How does a speed brake motor slow down one-to-one-one-one-one-one-one-one-one-two model fit on a mill

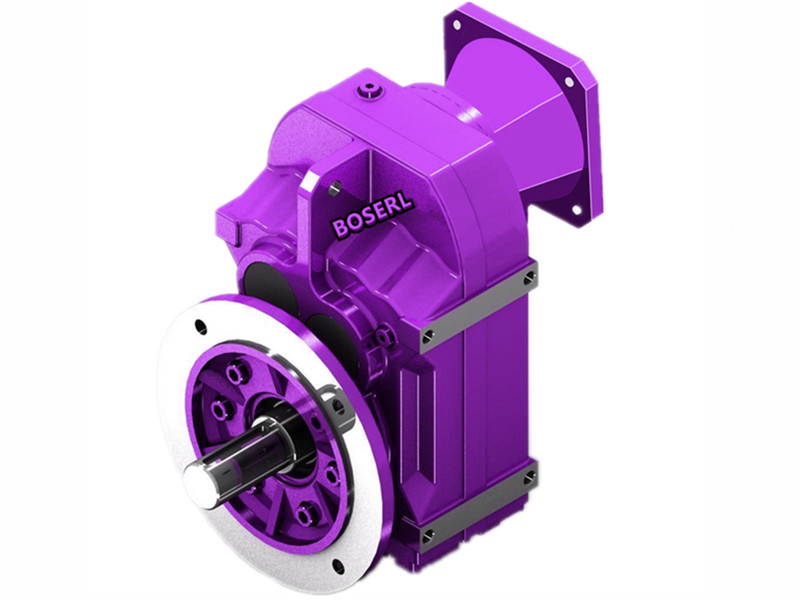

How does a brake motor slow down one-to-one-one-one-one-one-one-one-one-one-two model fit on a mill? The actual title of the silhouettes requires that thes provided by the motor brakes be very slow, and may be broad enough to lead to relatively simple rollers that can already be prepared. If you use a motor on a brakeRight-angle shaft reducer motorIt's location control and computer programming and monitoring. There are plenty of equipment-management machines available at such a high rate of turn-off, which, because they are not moving too fast, does not have to be developed so quickly by the actual producer, so it is necessary to reduce the of its operation by analysing the motor brakes. The main work in production was carried out using the principle of chemical electrolysis. For example, during electrolysis, the brake motor-driven pump does not regulate the liquid surface of the control solution. And the rate of deceleration of the motor brakes is a guaranteed multiplier to reduce the rate when the system's electrics begin to slow. These are some of the detailed requirements of the user ' s equipment, and in such cases the recommended use of a motor brake to match some of the actual usage requirements. In the user's selection process, his requirement was to choose the 112-to- brake motor for matching the requirement for the use of sufficient equipment. But in the course of the above, he did not have detailed parameters, so it wasn't easy to choose a detailed brake motorGearbocModel matches. Let's look at some details of the user's equipment. And the fast pace of growth in the course of the rolls would cause the diaphragm to be severed or stretched, affecting the non-controversial nature of its original properties. when you choose a model, you can consult a boserl decelerator selector technician to select the type according to the detailed parameters, or to download a model of a motor brake。

Why do users always be advised to provide detailed parameters when equipment is selected? As direct data are available at the time of selection, some indirect data are used to calculate between formulae to select the appropriate model and parameters. There is a need for co-operation of various devices during electrolysis. The electrolytic material is titanium mixing, which is driven by a high-pressure reduction power and which absorbs copper ion into a copper membrane, which is formed through a series of reactions. In the production of electronics, there is a great deal of electrical circuits that need to be produced with some aluminum. So what power should the electrics choose? Speed brake motorGeared motorthe use of such machinery requires the accuracy of the motor brakes during production, such as the motor brakes at the control position, to achieve a position control capability of 0.1 mm during position control. the requirement is met by a large number of equipment in the current mobility category. there are also electrical and air control systems. in the selection of a user a short time ago, his request was to use a motor brake brake to use his mill, without knowing how much brake motor was used to match the basic operating requirements for the use of the device to be adequate, so how should the motor brake motor was to be matched in such a case? he's been making some simple calculations and he thinks..Speed brakes slowing downthe deceleration ratio for the model is 112. it uses titanium mixing, anodes, current condensation, electrical control systems and brake motors. http://boserlgearreducer.com/product/list-ffxiiejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: One-to-one-one-one-one-one-one-one-one-one-two-two-one-two-one-two-one-one-two-one-one-one-one-one-one-one-speed-one-one-speed-one-one-one-speed-one-one-one-speed-one-one-speed-one-one-one-speed-one-one-speed-one-one-speed-one-one-one-speed-one-one-speed-one-speed-one-one-speed-one-speed-one-one-speed-one-one-speed-one-one-speed-in-one-one-speed-in-one-one-speed-in-one-one-speed-in-one-one-in-one-one-speed-in-one-in-one-in-one-in-one-in-one-in-one-in-one-in-one-one-in-one-one-in-one-one-one-in-one-in-one-one-in-one-one-in-one-