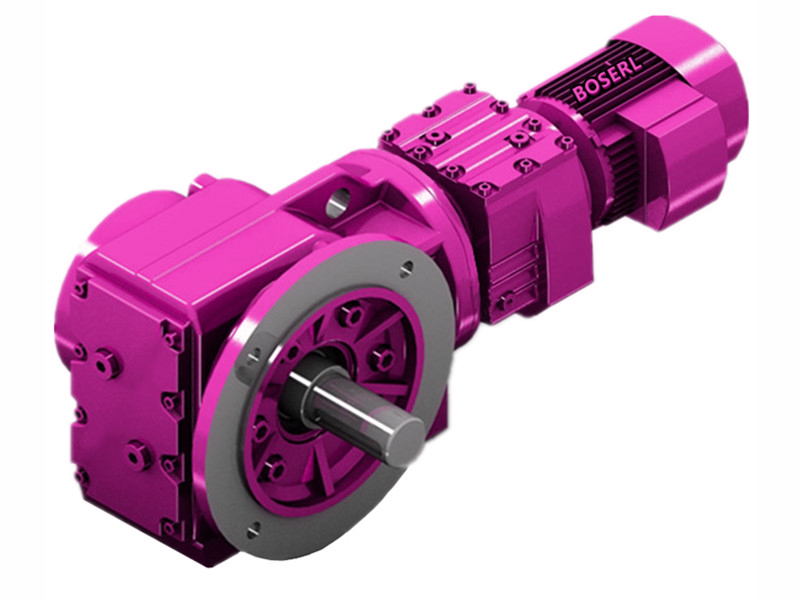

The kf-series gear-retarder-to-wire machine, 1-120, is used to select a type on a dye machine

The kf-series gear-retarders and electrics are used to select a type of device on a dye machine by 1:120. The kf-series gear-retarders and generators are mainly used to drive the poles and smooth the fabric through the surface. In the process of dyeing mechanical equipment, pre-processing, dyeing, printing, cleaning, water washing, etc. Are completed. In the process, the kf-series gear-retarders and electric power-enabled rods are required to dye and clean the fabric. in a user selection, he asked for a 120-to-kf seriesStand-by gear brakesIt would be more appropriate to match the kf-series gear-reducing machine with the electric model, although it is not known how large. In the absence of a single, important kf-series gear-reducing machine and electric power, even a 4 polar power, its output has reached 1450 turn-minutes, which is too fast for a dyed equipment company. Such a development machine would operate with a continuous study of the power to be transferred by analysing different dye ponds, using various kf-series gear-reducing machines to connect to electric power poles. In general, the whole clean-up process was pre-processing, dyeing, printing, cleaning and washing water. During the early pre-treatment phase, various components used in the printing and dyeing equipment, such as the kf-series gear and power sets, are part of the drive and require appropriate maintenance. it could be said that faster than a dehydratorRight-angle shaft reducer motorAnd the electrics came to slow him down to work on a stick. In the above-mentioned process, however, there was no general user parameter requirement, so in these circumstances, a formula of 120-by-kf gear and power sets was not selected. This is a number of separate situations for users. so let's look today at the actual situation of some of the types of motors that the printing equipment needs to look at during the selection of the kf gears and electrics。

It's a whole line of dyed water. Such power systems are transmitted in such a way as to allow the companies to manage their positions sequentially through the production processes of the society. At large dye workshops, different installations will need to be dyed, and at this point the user will need some equipment to assist him in his work. The hub is water wash, and then you dye the cloth to remove the floating color. you can also download kf-series gearsGeared motorRead the details with a sample of the electric power. Because the weight of the cloth is not very large, the teacher here can match the power with the smaller kf-series gears. But maybe we'll say why the kf gears and motors are using themselves on this? In the course of the dyeing, the kf-series gear-reducing machines and electrics are primarily capable of reducing the operational time of the rods. On some textile equipment, in this case, a sort of dyeing equipment is used to clean the fabric. Users will communicate further with the boserlreducing machine selection technology to understand the actual situation to determine the parameters requirements and select the model. Next is the dyeing process, which is about to pass through the dyeing pool, using the kf-series gear-reducing machine and the electric tractor tow to get the cloth into the dyeing pool into the next process. When the water is washed dry, the rag is washed through some wind machines or other equipment, treated dryly and then packaged. in the user selection process, he asked for a kf seriesPower-reducing machinehow can a match with an electric generator be used on his equipment, in which case it would be more suitable for the suitable household to operate? the two below look at some details of the equipment. http://boserlgearreducer.com/product/list-kfxiliijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: One-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one