One-to-141 speed-reducing machines are used in crowding transporter selection cases

A 1-to-141 second-rate decelerator is used in the squeezing transporter selection case. In the user's selection process, his request was to use the electric second-stagereducing machine on his equipmentGear with motorFor 141, how would it fit in such a situation? Take a look at some details of the user's equipment. He knew that the second-stage decelerator he needed was in the form of a straight-angle output installation. His squeeze transporter required an operational load of about 5 tons, and there was no data in detail, only a rough one, and at the time of the equipment selection, he had chosen the type of a secondary decelerator with only 4,000 nm. His other request was not to go too fast and the five tons mentioned above. In the selection of a user in the recent past, a user ' s requirement was to use a 1:141-level-ii decelerator for his squeezer transmitter, and in this case how should the corresponding secondary-rater model be matched for his equipment? The corresponding secondary decelerator model is then recommended for matching on the user's squeeze transporter. since all he could offer at the beginning was learning to provide a load of about 4 tons, possibly more than 100 kg, or 100 kg, which would have been more than 100 kg if it had actually been in productionLevel-IIreducing machineThere is a lack of output, so that it directly leads to a situation in which the squeezing machine begins to spread over many disasters when it operates. Because the output of the secondary reduction is a value, this value can be compared. It is only by comparing the size of the plate that the detailed range can be further understood。

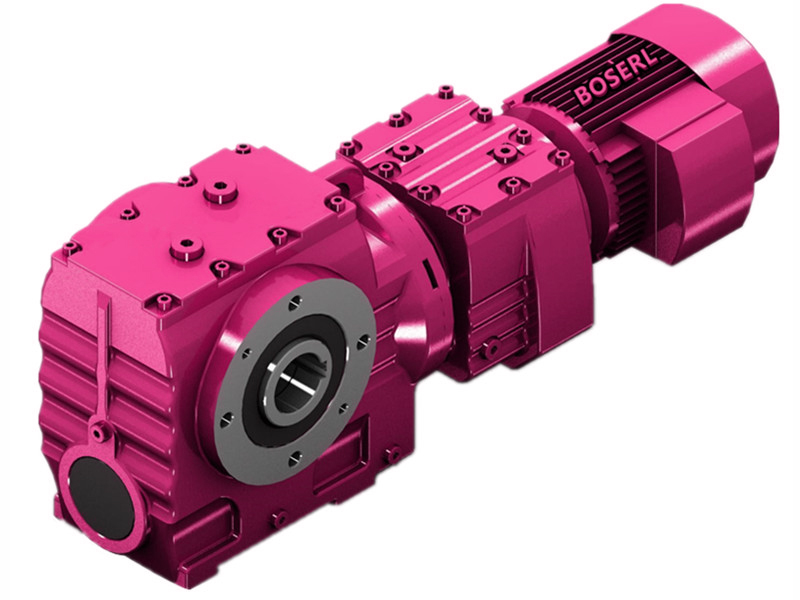

Details can be obtained from boserl's second-levelreducing machine or downloading the second-level techGeared motorSelect the sample to see the detailed parameters size. Based on the details of the installation of thereducing machines for the four series, we can lock in that he needs a second set ofreducing machines, either a k-reducing machine in the four series or a s-scalder snail. However, in the above-mentioned cases, the model cannot still be determined, since in the selection of the secondary decelerator we do not know the of transmission of the user's equipment, in which case it is not easy to match the power, when the requirement is slower, with the option of matching it with a 6p power plant, and, if no special requirement exists, with the option of matching it with a 4p-server, with the details of the user's actual operating environment and of how many poles it is appropriate. In some industries, the matching of the corresponding equipment with the corresponding equipment is done to select the corresponding device for operation. There may be some dyslexia in the operation of significant advances. so in an earlier chat, he asked for a 141-to-one cut-offServo motor reducer, drive a load of 5 tons. The recommended model may therefore be a S seriesreducing machine with at least 400 NM and it is difficult to determine what he needs, not too fast. Squeezing transmitters are mainly used for the operation of powdered or slurry-like substances, sometimes requiring larger output twists, sometimes requiring less large output twists, and then how should they be accompanied by a 141-to-141 secondaryreducing machine to operate? Here are some details of the user's equipment. This is the details of some of the equipment provided by the users. http://boserlgearreducer.com/product/list-saxiliejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: One-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-