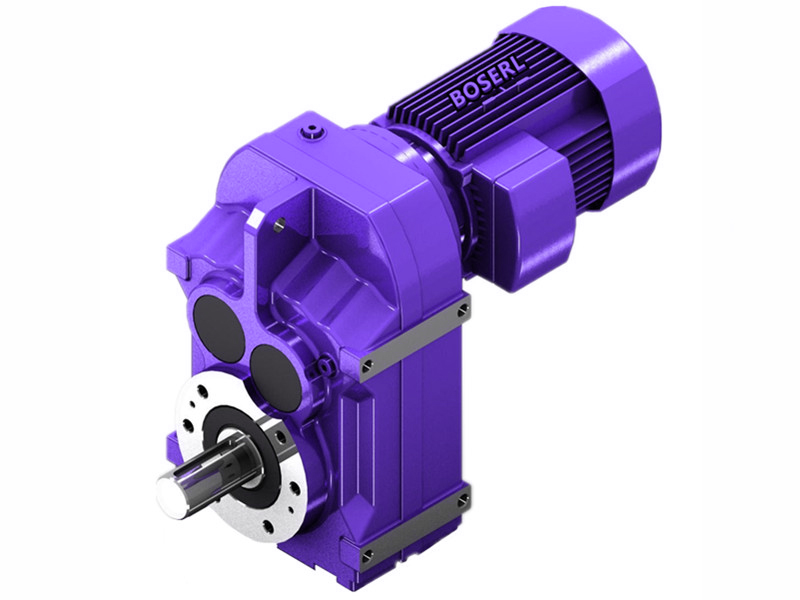

4. 5kw/4500w power model size f series speed-reducing machine

4. 5 kw/4500w power model size of f series decelerator. in the user's selection process, his request was to use the 4,500 w power setInduction motorIt's not easy at this point to choose a detailed model, so we're making sure to use itGeared motorLet's look at some details of the user's equipment. Full-automatic packaging machines are machines capable of automatically completing the packaged product, with automatic delivery, automatic packaging, automatic sealing, etc. This would facilitate the equipment ' s selection of the appropriate model and the corresponding functional parameters. Well, let's see the fully automated packer todayInduction motorSelect some of the situations. This is the user's deviceInduction motorSome things。

Packaging machines, including bottoms, substrates, transmissions and partitions, fixed at the bottom of the substrates, transmissionsInduction motorFixed at the top of the base, fixed at the top of the subdivision at the top of the base and covered at the left of the conveyor, and also at the top of the fixed shelf, the material bar, a powerer, the active wheel, a cylinder, an installation plate, thermal press, thermal voltage, springs and buffers, fixed on the top of the fixed shelf with a clamp on the upper part of the fixed shelf and installed on the upper part of the fixed frame through a holding mechanismGearbocFixed on the back of a fixed frame, active wheel is set in the centre of a fixed frame and connected to the output end of an electrical generator, from the centre of a fixed frame on a rolling wheel and on the right side of the active wheel, the sideboard is set on the left side of a fixed frame, a cylinder is set on the centre of a fixed frame, the installed plate is set on the bottom of the first cylinder, thermal pression is fixed on the top of the installation plate, thermal pressure is set on the bottom of the thermostat and is set on the bottom of the installation plate, the buffer plate is fixed on the bottom of the plate, and the holding apparatus consists of two electric machinesInduction motorc. Rears, one plate, plugs, two cylinders, two cylinders, two cylinders, fixed in the rear of the fixed frame, set in the front of the second generator and forward through the back of the fixed frame, one plate fixed in the front of the rectangular, a plug in the front of the plate, a plug in the back of the wheel, two cylinders fixed in the front of the fixed frame, two plates fixed in the back of the second cylinder, and protection over the centre of the fixed frame and over the outer side of the installed panel; When the product is sealed with a fully automatic stretcher packaging machine, the power is activatedInduction motor, line the product down to the thermal pressure, fast-track the irradiation on the shelf through the holding, and pull the packaging membrane out of the transporter through the active wheel and from the gap of the wheel, and then throughReducer+MotorDrives the active wheel rolls the packaging membrane constantly out, and then activates a cylinder that puts thermal pressure down and completes the encapsulation. In the composition of the heat pressure, the buffer sheet first comes into contact with the conveyor, presses the packaging membrane under the spring and acts as a buffer, mitigates the impact of thermal pressure on the conveyor, while fast-fixed replacement of the material by a collage structure, effectively advances production efficiency, is more practical, and protects the dispersion of thermal pressure by protecting the shield。

Its strengths include improving productivity, reducing labour costs and reducing packaging errors. It is often widely used in the food, express delivery, cosmetics and solar-chemicals industries. One of the design staff's requirements is to use a power supplyInduction motorAs a driver on his equipment, in this case his request was to use 4. 5 kw powerInduction motorMake a match, not knowing the size of the choiceInduction motorThe model is more appropriate for matching. But the above descriptionInduction motorIn the selection process, there are no detailed parameter requirements, so it is not easy to select a detailed model to match the equipment, at which point the Induction motor models on the selected sample that match the 4,500 W power are: F57, F67, F77, F87, F97, F107 and some combinations of models that can be used, with detailed selections that can consult BOSERL selected technical staff or download samples. http://boserlgearreducer.com/product/list-fxiliijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: 4. 5kw/4500w power model size f series speed-reducing machine