7. 1 kw/7100w power model size s-series speed reduction

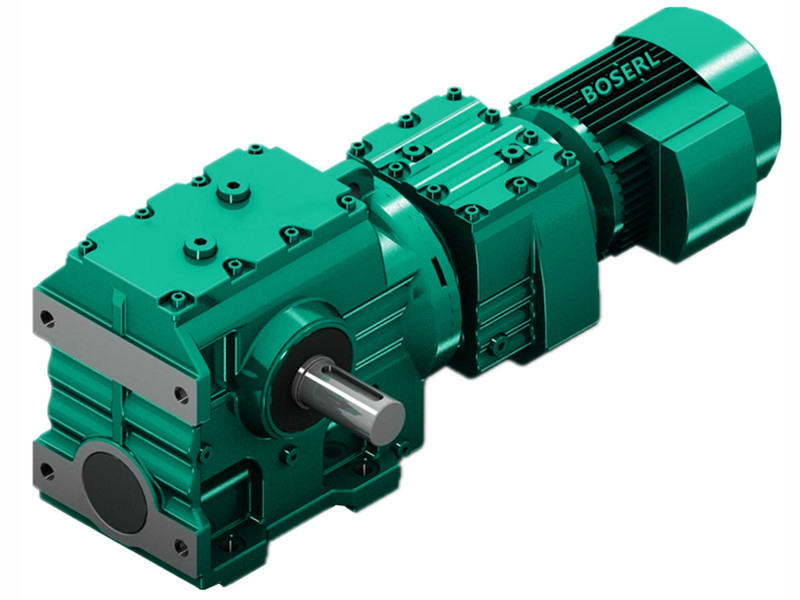

7. 1 kw/7100w power model size of s series reduction machine. A user's request is to use a 7. 1-kw-series sreducing machine on his equipment, and in such a case, to choose the twist that fits his device and the output that is used on his deviceVertical reducerSomething about the electrics. The parameter requirements are not provided in this user selection, so in such a case the configuration on the selected sample is considered and the selection sample is matchedHelical-worm gearmotorThe models are: s77, s87, s97, s107, s127. this is the user's equipmentHelical-worm gearmotorSome things. Detailed equipment selections can be done by consulting boserl selected technical staff. a longitudinal wiring around a silk frame is being pulledHelical-worm gearmotorPulling forward to the scrolling device, where the amount of horizontal metal wiring, which is actually required, moves the slides to the required position, and locks it to the point where the two threads are locked, and when the lateral wires are transported to the slide track through a tray from the storage platform, because the surface of the delivery slide is higher than that of the slider, the lateral wire is not inherited from the slides, when the cam wheel and pusher, the midpole, the top poles send the power to the forklift, which is used by them under the extension attached to the positioning saleHelical-worm gearmotorWhen the machine presses the delivery material, the horizontal wire in the gap between the pressure device and the delivery slide will be correctly delivered to the position of the welding device through the delivery track, and will be subject to a limit, the limit sales and magnets will position it quickly and smoothly, welding it with the vertical thread by working together with the upper and lower welding head, and pressing the lateral metal in the slide by placing the pressure on the pressure device through the fork and springs in order to achieve that the horizontal wire in the gap between the pressure unit and the delivery track will not fall further. Only two parameters require that we do not easily select a detailed model for matching use, so in this case we need to look at some of the user's equipment, and then choose the corresponding electric power andSecond-stage brakesModel。

Welders can be used in the manufacture of metallic wire products for construction purposes, such as safety nets, safety nets, quarantine nets, etc., which have an important role in the construction of welders in a variety of areas in which they can be considered to provide efficient, accurate and high-quality metallic wire manufacturing services. After the action, the pressurer and the delivery slides are repositioned through the spring and the second spring, respectively, into the next round. Electrics, conveyor boxesSeries sGeared motor" , laminate, roller, roller, loader, welder, winder, towcht, on the right side of the projectile, the storage platform in the projectile, the steering slide and the delivery slide are successively slanted from the top left to the right, and the storage platform, the steering slide and the lower end of the delivery slide are on a straight lineHelical-worm gearmotorThe upper end of the driver slider is above the upper end of the steering slider, the storage platform and the main end of the steering slider are fitted with a transferor pallet, the steering slide is fitted with a pressure device, which consists of a vertical pole, the middle end of the suspension arm beam, the end of the suspension arm extension, a lock button, a slider, a spring, a spring, a groove, a trough, one end of the vertical pole is connected to the steering slider, the other end of the vertical pole is connected to the arm beam, the middle end of the suspension arm and the upper end of the suspension beam are held with a lard, a slider is placed on the upper end of the suspension arm beam, and is connected to the slide by locking the slamming button, the other end of the zipper is connected to the forklift, and the extension of the forklift is attached to the fork wheelHelical-worm gearmotorThe other end of the delivery slide is connected to the middle pole through the top pole, the other end of the middle pole is connected to the pole, the other end of the pole is fitted with a wheel, the wheel is aligned with the cam movement, the cam cam is connected to the output axle in the moving device, and the delivery slide is accompanied by a second spring connected to the body. When the user chooses the match for his welderHelical-worm gearmotorAt the time, he asked for a 7,100 w power setServo motor reducermake a mix. http://boserlgearreducer.com/product/list-sxiliejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: 7. 1 kw/7100w power model size s-series speed reduction