Gear-reducing machines with EMP environmental design parameters

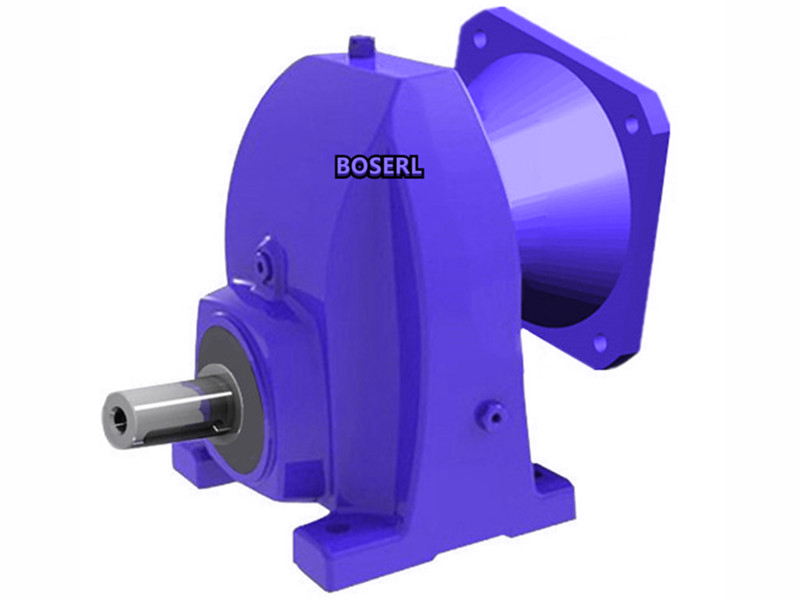

Gearreducing machines are equipped with EDP parameters. In the context of the need to use blast protectionGear boxThe EMP solution is based on the PMSM series, which is an environmentally friendly electrical series designed with high-efficiency rotors, and incorporates embedded inert permanent magnets made of rare earth metals in place of minimum temperature rat cage rotors. The design of the blast-proof gear-reducing gear with a protection level of up to IP66 and the need to replace lubricants only after 15,000 working hours is an ideal option for applications of critical reliability. As a result, B0SERL developed the Ex-rated IE4PMSM GearK series ofreducing electric power, which provides the same level of energy efficiency as the rest of the series and the ATEX classification for sectors 1 and 21. They also help to reduce the maintenance costs associated with applications. This is linked to gear brakes, which provide up to 18,500 Nm of rectangular value and high output. In addition, by applying B0SERLAn umbrella gear-reducing machineThe expertise of blast-proofing power plants can significantly reduce the price premium and operating capital associated with the electric power that is usually designed to operate in a zoning environment. for those involved in the chemical processing industry, there is no need to compromise on energy efficiency because the application requires atex certification equipment。

Applications in explosive hazard areas are not currently subject to the eu definition of minimum energy efficiency and, as it is clear, blast protection takes precedence over energy conservation. Compared to the most efficient conventional power, it reduces the heat loss of rotors by 100 per cent, the total loss by about 25 per cent and the overall efficiency improvement by 10 per cent or more. For pmsm users, this improved functionality translates into lower overall ownership, reduced co2 emissions and continued savings, thus mitigating future increases in energy capital. b0serl provides high quality and reliability of german engineering products, which are used in a variety of applicationsGear motors: Spiral, tilt, axle installation, snails, detached single-track and integrated reverser drive units (including IE4 selections) for general applications, in addition to ATEX rated devices for hazardous environments. This would ensure that maintenance managers optimize their spare parts inventory and avoid additional technical training for new reversers. The PMSM design provides many hubs with wind. Electrics can be easily integrated with variants, such as Danf0ss FC-302, to ensure that the required is maintained at each stage of the mixing process. In an attempt to improve overall site efficiency, petrochemicals, oil and natural gas and mining industries are at a disadvantage. B0SERLMotor gearedno such restrictions were imposed on the application, and there was a greater tendency to promise to the client to use the reverser best suited to the situation. in many cases, manufacturers of special appliances such as s have designated specific reversers to be installed as a sector of application. the voltage sensor. http://boserlgearreducer.com/product/list-tongzhoujiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Gear-retarder with blast-proof power