4-5kw motors select a stand-down and output is 1/15 per minute

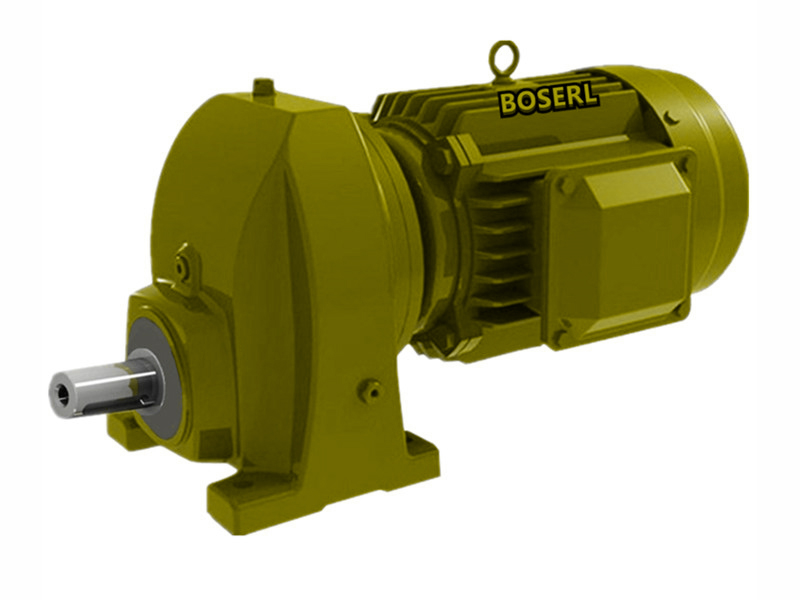

The 4-5KW motor selects a standing decelerator with an output of 1/15 per minute. a As the user limits the power of the gear-reducing power to 4KW-5KW, we can narrow the selection. If you chooseInduction motorIn the case of the 012KW, the selected use of the FA107RF77reducing machine for mechanical use, the functional parameter at this time is an output of 006r/min, an output twist of 13,900NM, areducing ratio of 22323, a safety factor of 085 and the R series gear-reducing machine in the same way that when the 180W power is used, the F seriesreducing machine can only be used to achieve the desired output-turning rate using a frequency-moder. However, a cursory screening revealed some contradiction between the output velocity and power that he needed and the high power choice. There are always a lot of different ways of usingreducing machines in the selection process, and different machines need to use them, so how do we face different circumstances in the selection process? Today, for example, how do we use available data to determine the details of thereducing machine? A user who chooses to use a 4-5KW power, acc, acce needs a power and a powerSnail scaldingwhen a combination is formed, it can be installed and installed, and thereducing machine is 1/15 per minute, so how should it be selected? an analysis of the user's needs, which he needs, is 1/15 per cent, then converted to the usual value of 0067r/min。

When the s-type turbine is selected, the output turns even more different, if the 012kw is selected for the turbine, it is only 012 turn minutes, while the 180w is used for 029 turn minutes. So it's not very appropriate to have a remarkable s series. So it's more appropriate to choose between the above. Turning first to the r-series gear decelerator, if it was 120w, the r147grf77 was chosen to deteriorate, with the output going at a of 006 per minute, at which point the 4 polar power was used. this power will makeGeared motorThe output turns to 0067 per minute. So we reduced his power to 120 w or 180 w. At the same time, the price of different electrons is different, so let's think first of all of using a level 4 machine, if we can't do it again. So what's the details of areducing machine that can meet this demand? We'll be able to get four series of slow-downs at this low -- to get rid of them and see if we can get this low. This is a very low rate of rotation, which usually takes the form of a combination of these. And that's-- well, it's down. The functional parameter at this time is the output twirl 13300nm, with a deceleration ratio of 21342 and a safety factor of 1. The rate of reduction would be approximately 20,895 at this time, if the 4 polars were converted to 1400; if six machines were used at this time, the rate of reduction would be reduced by almost half to 14328, while if eight poles were used, the rate of reduction would be reduced to 11194. As this output turns at a relatively small rate, the formula based on thereducing ratio can be seen to be very large. The output varies considerably, and the frequency is in the range ofs. Then we'll have to.Motor gearedIt turns into a veloctive form. The choice to use a K-type straight-anger is only 008r/min, and only 009 turns if 180W is used. However, if the 180W power sets were used, it would only be possible to turn 009 per minute, and of course the option would be to make the appropriate adjustments - down - with a variant. http://boserlgearreducer.com/product/list-rfxiliijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: The electrics select a flat-speeder