How do second-stage brakes and electrics turn 59 per minute

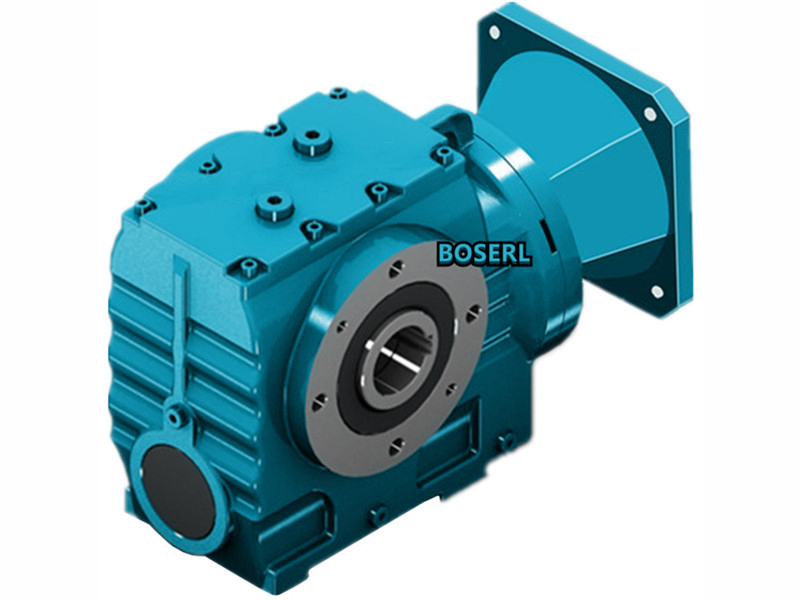

How do second-stage brakes and electrics turn 59 per minute? At this point in time, when his output turns 59 per minute, how do we fit his plate cutter better? Let's take a look at some of the details of this equipment selection today. This is the connection between some of the devices of the user ' s equipment. User's plate cutting equipment includes fixed frames, electric stretchers and floors and driveServo motor reducerWith the power. We recommend that users use the s47, s57, s67, s97 models for secondary retardors and electric generators. A screwdriver is placed between the front and the back of the fixed frame, a set of electrics is attached to the back of the fixed frame, the first line of a straight frame of the screwdriver is attached to the output axle of the secondary decelerator and the electric generator, the surface of the screwdriver is connected to a slider, the slider is connected to the cutter, the two two fixed frames are set on the left and the right sides of a fixed frame, the inner wall of the fixed frame is placed on a moving board, the pressured assembly is attached to the pressurized plate, both the cutting and the said pressured component are located above the floor, the electric stretcher is placed on the bottom plate, and the one end of the fixed frame is connected to the side of the electric stretcher. It also includes a support plate, which is set at the top of the said base plate, with a cutter, which is directly below the cutter. During the production of some of the plates, it is sometimes necessary to cut them according to their actual use. in the user's description, he asked to use level 2Geared motorCombination with the electric selected type is used on his equipment, and in this case it is not easy to select a detailed type. The front and back walls of the two fixed frames have a slider and the side side of the flowboard has a second slider that matches the slider. The cut assembly consists of a stairwell, a cutter attached to the output end of the electric generator by a secondary brake placed inside the stairwell, and a stairwell connected to the slider in question by means of a link pole。

In the process of selecting the second-stage brakes and the electrics for his equipment, the user was asked for parameters, which means that in such a case, the equipment should be considered and then selectedSecond-stage brakesIt's better to match the power plant. In the process of cutting, some of the materials are hard and others soft. By setting a slider, it is possible to limit the track of a slider and avoid deviation. These models, however, meet the user ' s needs for use, and can be detailed by downloading a sample of secondary brakes and electric generators or consulting boserl selected technical staff. Through the spring's kinetic force, it is better able to hold the plate tight and avoid deviation. The pressure assembly consists of a pressure pole and a pressure plate, the top of the pressure pole, a lined flow plate and its extension to the outside, the upper end of the pressure pole with a limited block, the bottom of the pressure pole with a connection to the pressure plate, the surface of the pressure pole with a spring, and the spring between the pressureboard and the flowboard. There are also two slides between the front and back walls of a fixed frame, two of which are placed on both sides of a screwdriver, and the first slider referred to is attached to the surface of the two sliders. By setting the cutter, avoid damage to the cutter. However, some cutting devices need to be used during the process. In the selection of a user on 22 october, he needed a secondary decelerator to match the power to be used on his equipment. when used, the plate will be placed on the support panel, which will need to be cut in the direction of the slot, activate the electric compression pole through an external switch, move the two fixed frames downwards until the top of the plate, then inherit the pressure, move the bar upwards, press the spring, then press the spring until the cutter can cut the blade, then activate the two different setsDouble-hole output reductionin this case, a second-stage brake is rotated with an electric wheel-led screwdriver, a screwdriver-led slider is slided over the length of the slider, a slider is moved through a connecting pole-led support frame, a second-stage brake is rotated with an electric wheeled cutter, and the plate is cut by moving side. see then what is more appropriate at this time when the secondary brakes and the electrics reach the parameters of 59. http://boserlgearreducer.com/product/list-saxiliejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Second-stage brakes and electrics turn 59 per minute