A hyperbolic deviator designed for food machinery

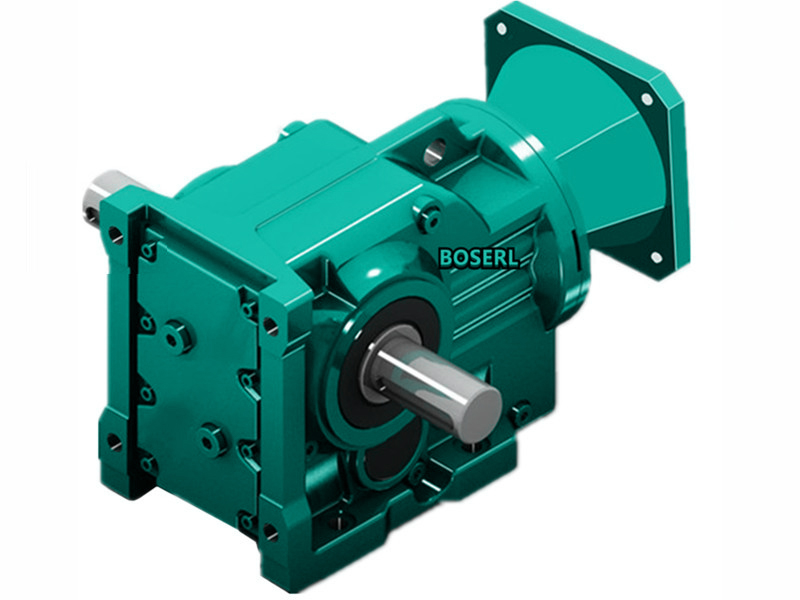

A hyperbolic deviator designed for food machinery. It's not always smooth. Humidity: cleaning the surface depends on its wetting. Food safety eu directive 1935/2004 (replaces 27) directive 80 / 590 / 89 / 109/eec) designates material food to which they may be exposed. boserl straight axisDouble- power deceleratorIt can be said to be a moving equipment designed specifically for food machinery and for pharmaceutical machinery. Here, the “good production practice” rule (gmp) is applied, which naturally means that the use of materials must not pose a threat to the health of any person (materials must be free of poison and physical safety). There are three possible states: complete wetting, water-related, such as those of stainless steel. A surface exposure to food must be easily cleaned. The key themes that need to be answered are: whether the food is on the material surface, what kind of surface structure is needed, what is the subject of the opening or closure process, what is used in the cleaning process, and how to ensure that the surface is sufficiently resistant to washing and disinfectant. food is a very sensitive subject, and to meet the requirements of the inter-european health organization, boserl engineer is designing a direct axisRight-angle shaft reducer motorAt that point, the whole machine could be said to be completely closed and smooth. In addition, the surface of micro and macro structures, whether they are subject to any change, is eroded, worn or stripped, even because of ageing。

There are strict legal requirements, which are selected from material. In additionReducer+MotorThere are additional statutory labels and traceability. Steel tracks: Paints and coatings - The choice of paint material is primarily used to protect them. Request: Each design engineer selects the production process in the heart of the particular food material. Retroactivity: All materials used in health-sensitive areas need to be traceable, covering: inspection; recall of defective products; proof of responsibility for products for consumer information. However, this “mechanical smoothing” is not sufficient. Liquids are distributed equally in objects. This means that the scale is strength and resistance to erosion, wear and temperature. Common materials include stainless steel - for most foods; low-carbon steel - for dry products and dry cleaning; and procedures or special products such as chocolate plastics (polymers and elastics) - special-purpose cable edges, skateboards, guidance tracks, etc. If the surface is rough, proof must be provided that it is easy to clean. The surface must be heavily tilted to allow for liquid drainage. The Directive also specifies that the materials used must be non-triggered ingredients that can change food or their sensory changes (effects on sensory organs) propertiesGeared motorthis means that they can neither absorb nor release the substance. http://boserlgearreducer.com/product/list-zhiajiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Speed-reducing machines designed for food machines