How to choose a single-ton coxlear slasher 37-minute load

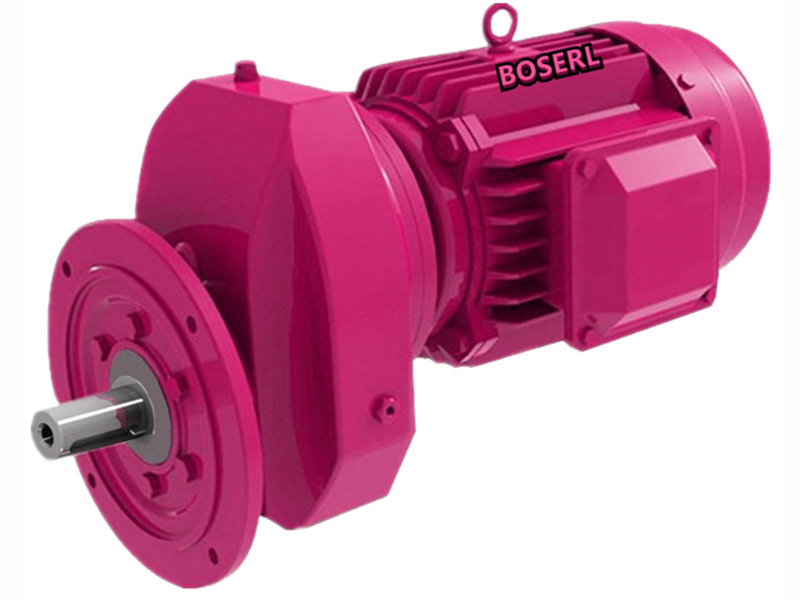

how to choose a single-ton coxlear slasher 37-minute load? the belt tray is installed on the internal side of the sideboard, the belt tray is located on the internal side of the conveyor belt and the sides of the belt tray are attached to the sideboard by bolt. the side plate is a c-shaped plate structure, and the side plate is installed multiplely at the top symmetry that supports both sides of the bottom shelf, and is connected to the side plate between the side plate and the side plate. drives a chain of mixed ends withVertical reducerThe end of the chain is connected through the chain. The side plate is installed at the top of the supporting side of the bottom shelf and the side plate is attached to the support frame through bolts, the side plate connector is attached to the inside wall of the side plate, the side plate connects to the side plate through bolts, the side plate is mounted on the inside side of the side plate, and the tight wheel is located at the end of the support frame, and the tight end is placed on the outer side of the sideboard through a tight device, with a tight mix and a tight device connected through the bearing. The chain shield is mounted on the outer wall of the side plate by bolting. In some of the larger construction sites, some longer conveyor belts are needed at times, and his load is larger, yet his delivery is not fast, so how do we fit the corresponding drive in such a situation? One user ' s request is that his conveyor load be 1 ton and that the of thereducing machine ' s output be turned to 37. The conveyor belt is placed in a tight, irradiated, driven external. This combination of parameter drawings can be obtained either by downloading a sample of an axle slasher or by consulting a technical staff member of the boserl slasher. If you choose to calculate using the parameters of the quadratic electric power, then the calculated power is about 4. 12 kw, then you can choose to use the 4kw power to match r97Geared motorThe actual parameters for the operation of his equipment can be satisfied。

This is some of the cases in which the equipment of the user used an electricreducing machine. The back-trail is installed on the inner side of the sideboard, the back-trail is located on the outside side of the conveyor belt and the back-trail is connected to the sideboard through the axle bearings at both ends. Block buttons are installed on the upper edge of the sideboard。GearbocIt is installed on the inner side of the support frame, and thereducing machine is located at the lower end of the support frame, and thereducing machine is attached to the support frame by bolt. Users ' belt carriers include: side plate connectors, side panels, support underlays, tight wheels, tight-stretching, drive irradiation, conveyance belts, belt boards, back-trailing,reducing machines, chains, chain shields, blockers, etc. The chain wheel is placed at the end of the wheel, thereducing machine, and the chain wheel is connected to the wheel, the axle gear-reducing machine. Such a driver requires that the operation of his belt transporter will be determined, and he would like to have a higher rate of transmission efficiency when the driver is installed, so that energy efficiency does not spread, so how would it be more appropriate to match the power-reducing machine? Today, the user’s belt-relayer is selected. So let's take a look at some details of the user's equipment. The drive of the coxlear slasher is installed on the inner side of the side plate, and the wheel is located at the other end of the support shelf, with both ends of the wheel being connected to the side plate through the bearing. In the process of using the power-reducing machine for the user's equipment, he is required to use the parameters, at a time when the output is 37 turns a minute, the load is driven by 1 ton and thereducing machine selected is more efficient than thereducing machine selected is recommended for useMotor gearedas a coaxial slash gearreducing machines are capable of operating at about 95 per cent, they match the actual user needs. http://boserlgearreducer.com/product/list-tongzhoujiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: How to choose how to load 1 ton at 37 turns