Snail snail speed-retarding machine classification and selection

Snail snail deceleration machine to drive classification and selection. Fluid motion is the movement of a liquid or gas as a working medium, which can be divided into hydraulic motion, which relies on liquid static pressure, hydraulic motion, which relies on liquid power, and air pressure, which relies on gas pressure. The movement is divided into two types of movement rate, which has a number of fixed transmission ratios (see transformers) and non-variant, which can change continuously within a defined range. There are gear transmissions often using gear transformers, and small power transmissions may also be used in turbos with bands or chains。Motor geared plus powerThe transmission should be carried out in accordance with the requirements of the machine work unit and in a better condition. Small power transmissions often choose to use simple devices to reduce capital. Snail snails are mechanically driven to suit various power and motor requirements and are used very widely. Hydraulic transfer is small in size and has a better dynamic function; however, the transmission interval is shorter. The movement can also be divided into two categories: fixed-motion-paste and movement-paste. Snail snail brakes are divided into three main categories: mechanical, fluid and electrical。Motor-gear reducerThe basic parameter for moving is the moving ratio. The no-varication motion is often used to form a control system to control certain objects or processes, which should be selected according to the requirements of the control system. Mechanical motion is the direct movement by means of a piece of equipment, in which gear and chain movement are condensed; friction wheeling and belting are。

Electricity transfer is the conversion of electrical energy to mechanical energy using the electron mind to drive the brain work sector. There are various forms of motion transfer in which the mechanical non-variant structure is simple and maintenance-friendly, but has a short life and is often used for small power transmission; the liquid non-variant is accurate, but very expensive. Liquidity transfer has specific input and output characteristics that allow for a good match between the power engine and the machine ' s work sector. High power transmission gives priority to transmission efficiency, energy efficiency and reduced operational utility. Requirements for start-ups, brakes, reverses, overloads, slots and emptys should also be taken into account in the selection of a moving device。Gear motorsWork units need to usechanges as much as possible, as they need to. The power range of power transmission is large, automatic control and remote control is easily achieved, and power is transmitted at long intervals. Hydraulic and pneumatic motion is also easy to output straight-line motion. When the working sector requests a velocities, a fixed-motion-comparison movement may be used if it is appropriate to adapt to the power engine ' s velocity; if the motor is not adequate to meet the requirements of the process and economy, a variable-motion-comparison movement should be used. RememberPower-carrying brakesa simple-structured mechanical movement should be chosen under the conditions required by the stationary-maritime-maritime-movable-facing function. pressure transfer is mostly used for small power transfer and bad environments. http://boserlgearreducer.com/product/list-wolunwomenjiansuji-cn.html

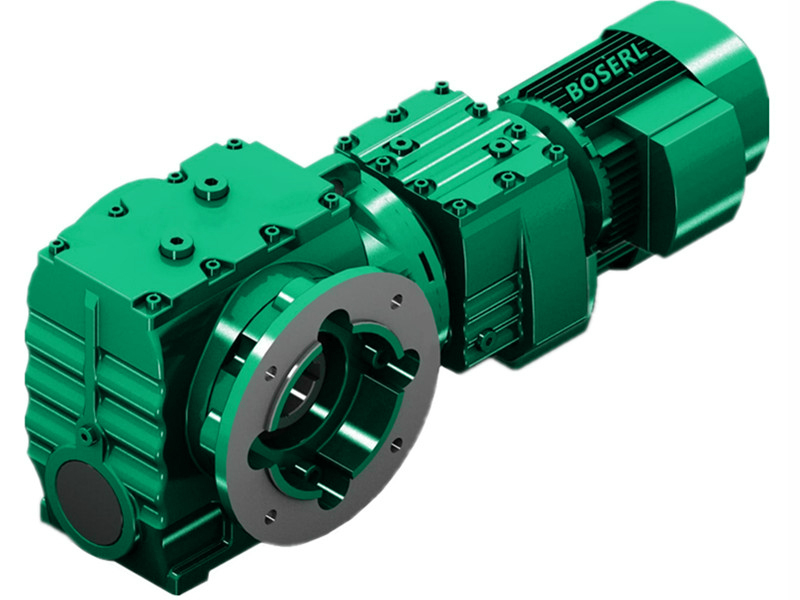

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Slow down