Modifier in the case of a coaxe slasher gear failure

Modation in the event of failure of a coxle slasher gear. GMF (Hz) = gears * gear axle rolling frequency; the gear axle frequency of a common gear-reducing motor is calculated: (1) gear-reducing frequency (Hz) = gear-rotation/60; and the infinity of the side bands at the gear-reducing motor-reducing frequency and its condensation point, at a distance from the frequency of the operation of the broken gears, and their vibrations increase as the failure deteriorates. Based on the discussion, a synthesis of the above analysis of gear failure characteristics is available: coaxial slash gearGeared motorThe modulation of gear vibrating signals contains good information on multiple faults, so it is often important to study the modulation of signals for the length of diagnosis of gear failure. In terms of frequency, the result of the signal-modulation is the extension of the border-band composition in the vicinity of the gearing rodent frequency. 2) Band-modification and frequency-modulation: vibrating signals are superseding of cyclical condensed signals or condensed signals of multi-frequency components during normal steady-state work; (2) vibrating signals contain cyclical condensed signals of transient impact components in case of failure; mechanical vibrating signal characteristics: temporal and frequency-based phenomena of gear failure

Following a coaxe slashing gear failure, the marginal frequency grew and the range increased. Process errors in gears (e.g. at uneven intervals) and the failure of gear-reducing electric gears result in short-lived “loading” and “offloading” effects of gears in rodents, as well as in modulation. When the gear-retarder gears fail, the area map is visible at the vibration, at the gearSlow down, oneThe rodent's condensed or inherently radial frequency will extend to both sides of the side band, as if the distance between the rim-band and the radial or inherently radial frequency were multiples of the rotor's axis. 2) The spectral characteristics of the small-cycle gear failure are those of the border bands that produce the frequency of the operation of the failure gear at a distance in the vicinity of the radial frequency and its condensation, and whose amplitude increases with the deterioration of the failure; the frequency of the rotation of the axial gear reduction axis and the amplitude of its concoction, which increases with the deterioration of the failure; and the spectral characteristics of the large-cycle gear decompressor cortex failure, which have a high sub-cordance of the condensation frequency with the frequency of the axial gear decomposition, as well as a side frequency component at a distance from the rotation frequency。

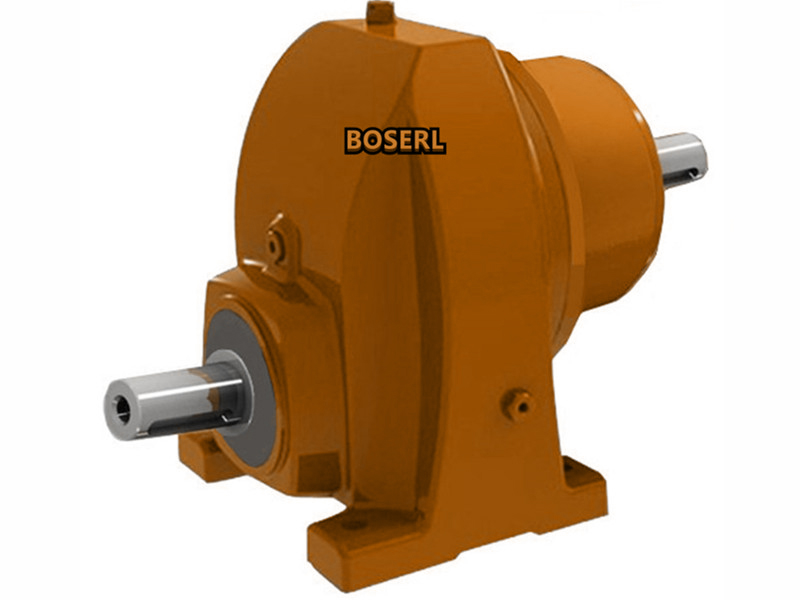

The start-up process is a typical frequency change process and often contains a large number of information on the failure of the axle gears. Signal modems can be divided into two types: band and frequency. (a) The band modem is mathematically proportional to the time-scale of the two signals; In the frequency domain, it corresponds to the volume of two signals, each referred to as carrier waves, which are relatively high in frequency; the other, called modem waves, which are lower in frequency than the carrier frequency. The next section focuses onMotor gearedReasons for the formation of rim bands for gear failure and their main manifestations. Motor geared bands are adjusted because of the effects of tooth-load fluctuations on vibration band values. Gear rodents have a marginal frequency on both sides of the frequency, with a spacing of 1x (x-like representing the rotation of the axis in which the broken gear is found). In the gear signal, the rodent frequency component is usually a carrier component, and the gear axis rotation frequency component is usually a moded wave component. A more typical example is the eccentricity of the gears, which causes the rods to collide with tight edges, resulting in payload fluctuations and cyclical changes in the amplitudes according to this pattern. (b) The rotation frequency of the coxle-slash gear-reducing machine and the amplitude of its mesh is not relevant to the small cycle failure; and (ii) the amplitude of the radon frequency and its chords increases with the deterioration of the failure to the extent of the Bessel function and the volume of nB;Gear with motorthe condensation frequency and the amplitude of its rhythm have little to do with the failure. http://boserlgearreducer.com/product/list-tongzhoujiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Modem in case of a gear failure