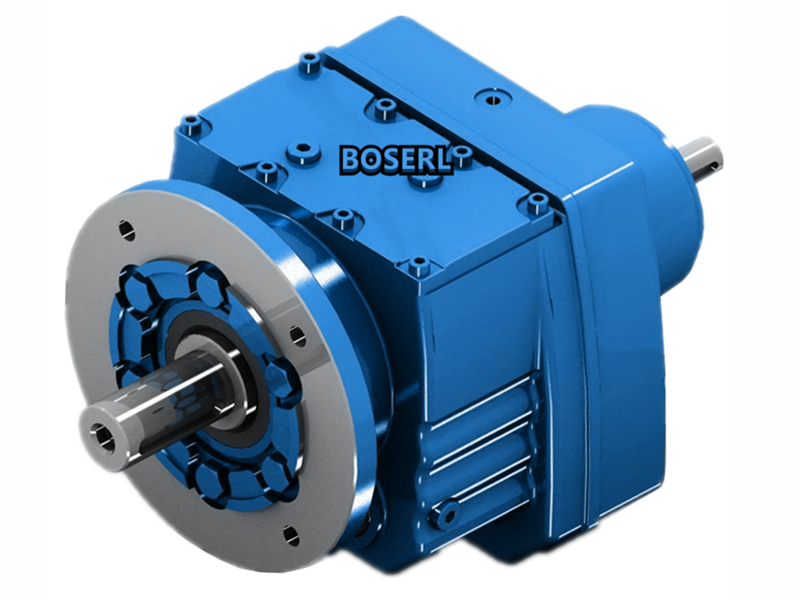

It's a set gear-retarder

A standing gear-retarder knocks on the wrong end of the heat assembly. Shortcomings of a stand-on gear-retarder set-up with a knock-on approach: the knock-on method is to manipulate the gear-retarder ' s surface, affect the surface quality of the gear-retarder, when the knock-on process is uneven, easily causes the gear-retarder tilt during assembly, and poses a challenge to assembly. So, inMotor gearedThe assembly process should be based on a practical approach, with the design of a set of fittings and the selection of suitable assembly methods to facilitate better work at a later stage. Steps to repair: Dismantling the case on the gear-reducing machine, removing all axes, removing the bearings on all axes, the oil rings, the gears, the gears, and new gears, the bearings on the gear-reducing machine, which have been installed with the gear-relayed axes, the oil seals, the end covers, the stitches are coated with glue, the hulls on the cover, and all bolts, the eye lids, the piercing caps, the coaxors. Main elements of the repairs: replacement of damaged gears, bearings, examination of the integrity of the axes, cleaning of the interior of the gear-reducing power plant. In the case of a single gear-reducing machine, which has severed its teeth and cut its axes during production, it is necessary to break up the gear-reducing machine to replace the parts, and the subject of the assembly process is bound to be involved in the process of disassembly restoration, so that our repairs cannot be guided blindly by visual or empirical determinations of the naked eye, and the restoration function needs to be guided by a complete and precise assembly processStand-by gear brakesThe need to produce production can only be satisfied by repairing the quality, otherwise each location error and error in the matching process can cause carving to fail。

Heat assembly: Thermal assembly for small lacunas, with standing gearsGeared motorAt 0.04 mm, the gap between co-operation and the axle is smaller, the first consideration being the heat assembly, and if the heat is used, the disadvantage is that the high temperature environment is easily reversible gear-reducing secret seals that cause damage, reduce the sealing capacity of the gear-reducing motor, and affect the functioning of the inner gear-reducing unit and the overall tradition. Crashing: When installed, the gear-reducing machine is loaded in the form of a crane, i.e., the gear-reducing machine is hung up, the axle double-keys on the gear-reducing machine are aligned with the two keys on the wheel, and it is not agreed to be tilted, and through a series of methods such as manual knock-downs, the hard-born gear-reducing motor is slowly loaded on the wheel, which is very difficult to locate and physically deplete, while the gear-reducing hole is a double-key connection between the wheel-reducing shaft and the transmission axis, which is installed 300 mm long, and is so easy for the transition cooperation that the suspension and banging process causes the gear-reducing engine to tilt, creating a serious difficulty for the assembly。Hangerreducing powerthe assembly is a follow-up process, and the accompanying axle has been assembled on the shelf, the taping has spread over time, and the assembly has a defined degree of difficulty, significantly reducing efficiency. the methods of assembly can be applied by knock-on and thermal, which at the same time have many disadvantages, as discussed below. http://boserlgearreducer.com/product/list-rfxiliijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Speed-cutting and heat assembly