Can a parallel axle gear-reducing plant drive 18 t-ton garbage disposal station load?

Can a parallel axle gear-reducing plant drive 18 t-ton garbage disposal station load? it's the basic condition of the user's equipment, and we can see it's used on his garbage disposalGearbocThe plant has two or three sets of electric appliances. This is more in line with the actual use environment and the parameters. This allows for a relatively equal distribution of the two broken sticks in order to achieve a good break-up effect and to extend the service life of the broken tatters and broken sticks. in general, only 18 tonnes of the load of only one equipment is not able to select the corresponding parallel axle gear decelerator manufacturer model, but for this type of garbage disposal equipment, it is recommended that the power drive on the gear-reducing device be used during a communication meeting with the user, in the case of a mechanical fragmentation device that is intended to be used for garbage disposal, including a feeder, a right-placer and axle wheel-reducing plant, a support frame, a slanted frame, a slasher, a rotary axle, a left-placer, a left-placer, a machine, a truncheon a and b。

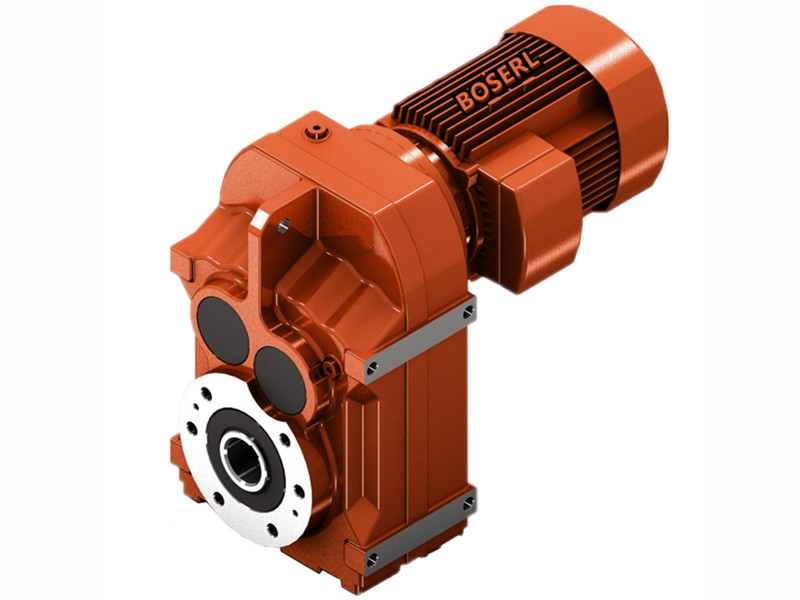

The clean-up of waste can eliminate pollution of the surrounding environment and groundwater in landfills, effectively eliminate the original source of contamination, improve the ecological environment and achieve significant environmental and social benefits through integrated management of obsolete waste disposal equipment. There's one other place on the device that needs this kind of transmission drive, that's when you use itElectricreducing machine - body machineEnables the drive belt to run, thus placing the device in a better auxiliary condition. The user sets two side-rolling shreddings, while the driver of the two broken, right-slashed, parallel-axis slash gear-reducing units and the left-slash-pattern-reducing units are placed on both sides of the case. The user wants to improve a garbage disposal device, at which point the overall load is 18 tons to run, and in which case should the number of parallel axle gear-reducing machines be selected to match the equipment ' s length? when the user chooses to use a parallel axle gear reductioner for matching use, we need to match it on a case-by-case basis, at which point we choose to use a selected sample of the manufacturer's own boserl axle gear reductioner to see some of the actual parameters of the equipment in operation。

I don't know. RightMotor geared plus powerThe producers of the left side tilt gears and the left side wheel gears are connected to the right side side and the left side side, respectively, to the right side and the left side of the car, respectively, and the feeder is placed on the top side of the said side. Based on the parameters requirements of the user and the operation of the equipment, we recommend that the user use the parallel axle slasher to produce the manufacturer, and at this time the parallel axle slasher to produce the manufacturer type selects the parallel axle to be used in a matching manner, since the parallel axle slasher to produce the manufacturer is capable of carrying a greater weight and providing a larger output twist to match use. The central part of the case, which is placed on the said shelf and its lower cascading, is connected to the shelf and the support leg of the two indicated tilt shelves, with four rectangular distributions and the upper end of which is connected to the frame, and the broken wheel a and the broken stick b, respectively, are connected to the production plant of the right side-axis and the production plant of the left side-axis tilt gear-reducing machine by a turn-axis and are paralleled in the said case. because of the different drivers usedGeared motormodels or functional parameters are different, so the selection of models and parameters is based on the actual circumstances. at the same time, a detachable feeder is set up and a vertical downward projection of the lower end of the feeder is between two straight lines at the top of the two broken sticks, thus facilitating the centralization of building waste into the work area of the broken rod, with good fragmentation. http://boserlgearreducer.com/product/list-pingxzoujiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Speed-reducing plant powered 18 t-ton waste disposal station