The role of speed-reducing motors as one conduits

(c) the role of thereducing power plant as a one-way conduit. This could be addressed by irritant treatment of thereducing motor one-lined mainway or the installation of a small sideway system (dn4-6) in the upper part of the one-way valve, which would then be returned to thereducing motor one-line tank. The second pollution will cause widespread contamination of the repulsive pump (e. G. for oil supply systems) after the commissioningMotor gearedthis phenomenon is due to the gradual formation of the slide face of its gear components by grinding or wearing metal particles, which are removed from the lubricants. the above-mentioned tests shall be carried out in a static (before the installation of the pumps) moderating motors, where a specially designed evaporation unit and pipe test pumps can be used. the total roundage of lubricating oil should not be too small, otherwise the frequent pumping process and inadequate cooling would lead to heat in lubricating oil, with a cooler or heat exchange, if needed. when a filter room is running, the others are in reserve. based on the detailed design status of thereducing engine, the rated filter is more appropriate in the range of 0.05 - 0.13 mm. the filter can be remotely monitored with visual differential monitors or electronic contacts in order to understand how the filter is gradually contaminated。

Pipes (especially when located upstream of the pump) are contaminated by fine impurities such as metal shredding, welding or welding residues, or grinding particles, which are produced during the manufacturing or installation of the equipment. Installed inMotor geared plus powerfilters of inhalation pipes can filter off alien particles of specific sizes. the output pressure or total resistance includes the resistance of each implementer, land pressure differentials and pipe resistance. in the case of oil, the corresponding flow of the of thedeficit motors, which is the same, is not agreed to exceed 3 m/s. note: alien objects can undermine the operational reliability and safety of areducing generator ' s integrated pump and lead to equipment jamming or a total machine shutdown, and a larger number of ultra-subsidiary contaminated particles can cause an acceleration-reducing machine to wear off the slide surface and reduce the useful life of the pump. the use of the pump is strictly prohibited. warning! the test pressure is usually higher than the design pressure of the pump and thus tends to damage the pump。

If the pump is used to pump the medium to the closed system (with a one-way valve); if the two parallel pumps are protected by a one-way valve. For a mandatory wheel-back lubrication system (e.g., a commonly used gear unit), thereducing electric unit purified filter will have to be installed on the export pipeline. Measures can be taken to prevent secondary contamination of gear pumps by installing crude or plate filters on inhaled pipes. Attention:Geared motorconduit and implementer resistance depends on the size of the medium viscosity. it is proposed to install an off-pressure valve on areducing motor unit to avoid overloading of pumps due to ultra-high pressure. forreducing motor unit lubricant, filters have rated filters in the range of 25-60um. be aware that pollution and silt causes the filter to be gradually clogged and thus reduces the pump ' s inhalation capacity, so that attention is needed if the pump ' s operating noise increases. if there is air in the inhaler tube, this could lead to the subject of sensing when the pump is activated, for example:

Thereducing motor unit is required to conduct a test of the working or output pressure by means of a pressure sheet, which is installed directly at the point of export of the pump. A good way to prevent secondary contamination of gear pumps is to install a conversion filter or a double automatic pass filter in the export pipeline and design it as a continuous filter. When selecting the rated filter and the specification of the filter, the point that must also be noted is the viscosity range of the corresponding lubricant, and therefore consultations with the filter manufacturer are necessary. PreventionGeared motorthere is a difference between the effects of electromechanical heterogenesis and pollution: secondary pollution is the fact that injections and injections are vulnerable to alien, impurity particles or mineral coatings, which are mixed into the medium pumped by the slow-down machines. the larger the filter area, the longer the corresponding maintenance period. http://boserlgearreducer.com/product/list-rxxiilijiansuji-cn.html

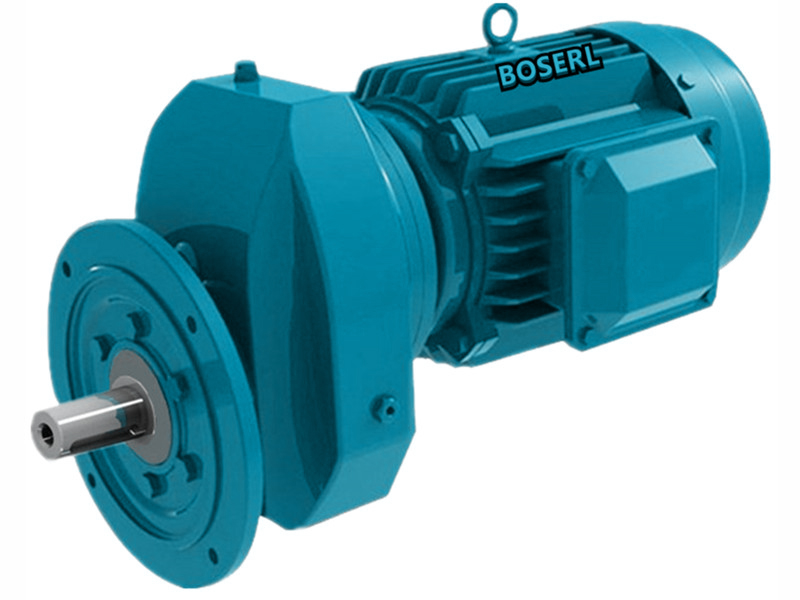

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: The role of speed-reducing motors as one conduits