Use and development of the r series speed-reducing machines

Use and development of the r seriesreducing machines. The r seriesreducing machines have a long history and have so far used a wide range of axle-slash gear-reducing machines. However, the other categories are essentially the deformation of conventional-type oil pumps, the rationale of which has not changed, and the coxlear gear reduction machines of different variants can only be adapted to the corresponding working premise. The following are the basic working principles of conventional-type r-series slow-down machines. The rapid development of today ' s society has increased human demand for energy, with oil as an ancient fossil energy source being the main source of human energy. It is broadly divided into the following categories: conventional, front-type, double-back head. the working method for a thorn rotation to an energy-efficient pump is: to be in the upper stagesGearbocUnder the lead, the thorn rotation is rolling in the direction of thereducing box, the chain-enabled chain and the pump poles are moving up and up to the intended upper-mortem position, the thorn rotation is shifting to the hydraulic system of thereducing container, the push-down rotation of the electric motor is rolling in the reverse direction to the r-seriesreducing machine, and, when the wheel is driving down the lower chain and the pump, to the point of death, the thorn rotation is shifting in the direction of the pressure-reducing tank system, and, if the wheel returns repeatedly, it completes the up- and down-to-the-up of the axle gear-reducing wheel。

Under the control of the smart-r-seriesreducing machine, the electrics roll back and then drive the pump poles up and down to the straight line, and complete the pumping of the rods. The structure of the r series ofreducing machines, which are specially designed for the plattered permagnetic press pump, is a single-barrel structure for the axle gears. However, the main obstacle to the current development of the axle slash gears is the lack of reliable and well-functioning switching devices. However, the r series.Geared motorThe sorghum oil pump, which is still widely used, needs to be multiplied in size if it is to be more aggressive, and has inefficiencies, among other things, resulting in the spread of resources and energy, contrary to today ' s philosophy of a resource-efficient, environment-friendly society. Intelligent transformer cabinets control the operation of a double-magnetic permagnetic power machine, with two wheels on both sides, one connected to a pump and the other connected to a heavy tank. The over-exploitation of oil has led to a rapid decline in oil reserves in major oil fields, and oil extraction by oil pumps has begun to move gradually in a long and low-spill direction。

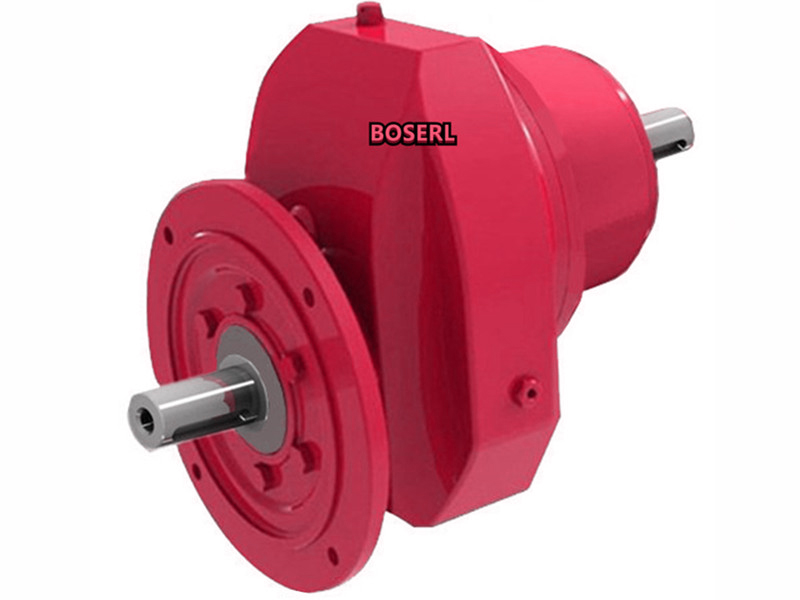

The sorghum oil pumps are highly reliable, but they are less and less well-resilient because of their inefficient oil pumping, their poor adaptive capacity and their inability to adapt to current conditions, such as the long- and low-slashing requirements of the oil field collage gears, and the fact that these topics cannot be resolved from the very long term makes their prospects for future development less and less optimistic。Motor gearedThe advantage is that the whole machine is simple, less vulnerable, has a high balance and has a long run. The disadvantage is that the double-magnetic integrator is so expensive, it has a poor ability to resist, it is restrained by a large turn-around, and it is difficult to start. The engine may or may be a power unit, such as a diesel engine, which provides power by slowing the brakes and boosts the rotor-strangling apparatus, which eventually transforms the continuous one-way rotation of the r-series brakes into the upper and lower swing of the beam, with the axle gear brakes connecting the pump poles to the ropes and driving the pump poles up and down the wells. The r series ofreducing machines for conventional beam pumpers continues to be the one currently using a wide range of pumps, consisting mainly of motors, coaxe-sorted gear-reducing machines, racks, and rotor-stretching agencies consisting of beams, rotors, chains, etc. at the same time, r-seriesreducing machines gradually show up with their sprinting and scalding, as well as the efficient and energy-efficient gear-reducing, etcHorizontal reducerdevelopment is increasingly being addressed. http://boserlgearreducer.com/product/list-rxiliijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Use and development of speed-cutting machines