The replacement of hyperbolic and snail brakes saved $50,000 a year

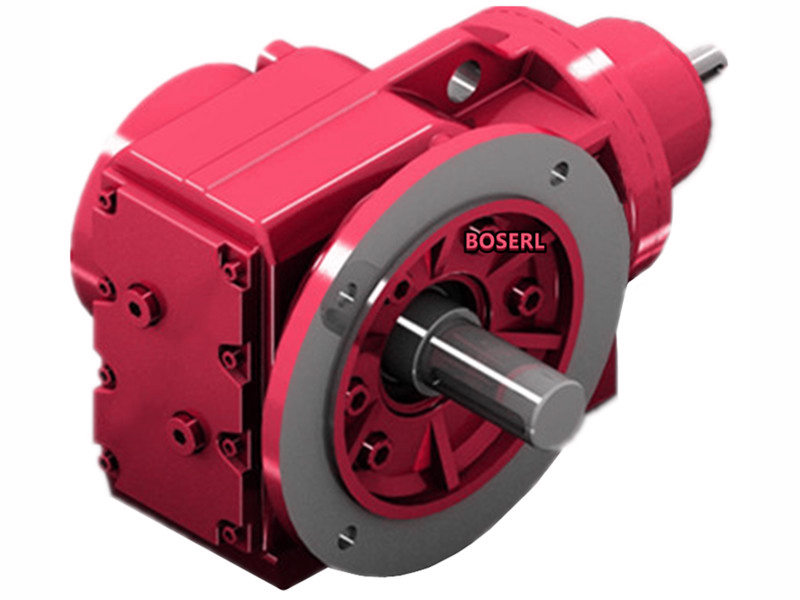

The replacement of a hyperbolicreducing machine with a snail snail has saved $50,000 a year. The following is a comparison of the parameters and energy consumption topics between the two slowing models. As can be seen more notably from the first and the first options, option II is more cost-effective, at a time when the option of using option II would result in direct savings of about $46,000 in expenditure, so an efficient transfer is selectedInduction Motor 3PhIt is true that an enterprise can be considered to be saving its own money in terms of energy consumption, and that, while the acquisition utility programme is more expensive than the programme, option II is better than the one in its subsequent use. At this time the efficiency is 94%, the input power P1n = (0.8+0.94) x 1 = 0.85 KW. Output twirl M2 calculation: M2 = 9550 x (0.8+28) = 272.86 NM can be seen with a safety factor of 1.0 for the type ofreducing machine. So when we learn about the input twist of the electric machine, we calculate the size of the output twist, at which point the output twist M2=9550x(0.8+28)=272.86NM. The installation size of the user was limited and his overall installation size was not too large, so in such a case he chose to use areducing machine in the form of a snail. So what happens at this point if a hyperbolic gear-reducing machine can be used to completely replace thereducing machine? Option two: If you choose to use a hyperbolic gear-reducing machine, because of their different efficiency, there will also be some difference in the selection process. And there's two of the B0SERLreducing machines in the series that meet his release requirementsRight-angle shaft reducer motorI don't know. When the deceleration ratio is 50, the corresponding use safety factor of fs = 1.176 can be seen in a snail snail snail-reducing machine sample, with an efficiency of 68%, then the rated power of the input power is calculated on the basis of P1n = (0.8+0.68) x 1.176 = 1.384 KW。

So his rated output is M2n=M2xfs=272.86x1.176=320.88NMGs snail scalding machineThe selected sample shows that the type ofreducing machine should be selected as 110-50-1.5 KW-1-4P. What about the energy consumption of thereducing machine? The annual electricity consumption of the output line is 22 days/month: Px8x22x12x40=*1.384x8x2x12x40=116920.32 (kW.h). And the deceleration ratio is the same. It's 50. How does he calculate his energy consumption? The annual electricity consumption of the production line decelerator is (calculated for 22 days/months): P1nx8x22x12x40=0.85x8x22x12x40=71808 (kW.h) calculated by industrial power use, and the annual electricity expenditure for the current line is: 7108x101=72526.08. Option I: If snail snails are chosen, based on the data provided by the user, our B0SERL decelerator Select Technical Officers have calculated the rate-reducing ratio of i = 1,400 + 28 = 50 calculated at this time through the rate-reducing formula and the parameters provided by the user. This is some of the case with programme II. His rated output is then M2n=M2xfs=272.86x1=272.86NM. An egg knife is available by means of a sample of thereducing machine of B0SERL, at which time the type ofreducing machine should be 38-48.18-90S4. The one-year expenditure on the water line, calculated by industry for electricity of $1.01 kW.h, was $1,16920.32 x 1.001 118089.52. A large enterprise will need to purchase 40reducing machines, requiring areducing machine output power of 0.8kW, n1 = 400mn, all impact reduction, 30 start-up frequency hours, 8 hours per day, hour, ambient temperature 32C, output velocity = 28rminGeared motorWhat's more appropriate? How do we match the corresponding brakes to be more efficient and less expensive? The B0SERL decelerator Selector Technician then provides users with two options. In this case, you can also see if your device is in a similar situation to match the corresponding decelerator. http://boserlgearreducer.com/product/list-zhiajiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: 50 grand in the year of replacement