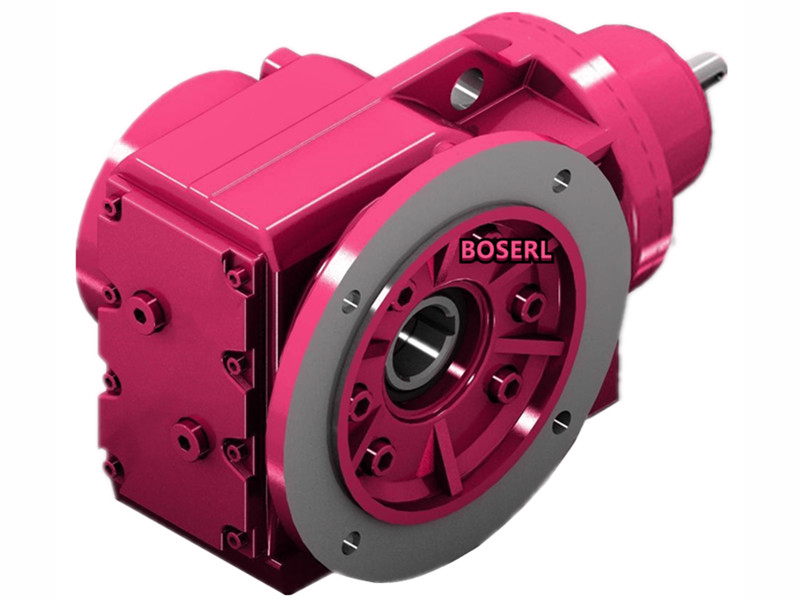

A typical structure assembly line for a hyperbolic decelerator

A typical structure assembly line for a hyperbolic decelerator. Such assembly lines are also often used only in the total vehicle assembly line and are less commonly used in vehicle parts assembly. When the car moves to the right place, the car will be locked directly and the process will be completed, for example, in the car. It's because it's simple, it's reliable, it's carrying a lot, it's lowDouble- power deceleratorAs a result of the ease of repair and maintenance, the assembly line can be rectangled and used widely when rotated within the horizontal surface, making better use of the size of the plant than other configurations. When an umbrella-axis slash gear-reducing unit reaches its working position, is blocked by a hyperbolic decelerator stopper and stops at its working position, the inner circle continues to turn around, generating a relative rolling between the inside and the outside circle at a time when the outer circle is static and has no movement relative to the bottom of the project, thus effectively preventing damage to the bottom of the project. This umbrella-axis slash gear gear gear assembly line, which is driven by a strip-drive chain to drive the body support car that is placed on the ground orbit, and the link between the car and the chain, which is plugged in, can easily connect or separate the car from the chain, and therefore can easily change the space of the car." A hyperbolic decelerator can produce a variety of different types and configurations of products on a line of assemblyGeared motorThe variety and number of products can vary according to the needs of customers. Non-synchronous flexible assembly lines include three elements: adaptation of assembly lines to new products; multi-species passability of hyperbolic reduction machines and assembly lines; and flexibility of umbrella and axle gear reduction machines。

This is preceded by several non-synchronous assembly lines with typical structures: non-synchronous flexible assembly lines allow for a significant and efficient use of the plant area. When the work is moving normally, the drive reaches the inner circle, then through the friction on the inside and the outside circle, which has no relative rolling. The friction-typed RV length synchronized assembly line is multiform。Motor gearedThe structure of the non-synchronous assembly line is very well structured, which greatly improves the time utilization and output efficiency of the assembly line and compensates for time and space consumption and empty lines when single products are produced as a result of missing items and backlines. The hyperbolic retrenchment motorized roller-track non-synchronous transmission is indirectly driven, with the drive transmitted through two rollers of the internal and external axis, with the inner circle receiving directly the drive from the power source, which is a friction ring made of special materials and installed in the inner circle, with a relative rolling between the internal and external circles (as in figure 2-5) "iii". the hyperbolicreducing machine exaggerates the basis of computer software, flexibility, adjustment and humanitarian space。

Free Rolling Road + Walking minivan. The basic structure of the umbrella-axis slash gear-reducing free-roller + side-car-style non-synchronous assembly line is as shown in figure 2-4. Track 1 is fixed to orbit 6 by bolt, and the side-wheeler 5 is free to slide on track 1, thus driving the side of panel 8. Its advantages are that the hyperbolicreducing machine is close, driven by low resistance, energy consumption and adaptation to changes in varieties, but that it is more expensive to invest in cars and that it also needs to address the return of the parasol-axis slash gear-reducing machine. The non-synchronous flexible assembly line of the umbrella and axle gear reduction machine has been able to develop rapidly because of the following advantages compared to the synchronized assembly line: normally, each large to-beam component is supported by three smaller vehicles, which can be designed according to the needs of the vehicle, as long as the former car is plugged into the driver chain. Floor chain-lined car assembly line. This oneRight-angle shaft reducer motorthe assembly line structure model is used widely in the overall assembly line of the paralysing gear-reducing unit, which is condensed with simple and compact structures, the use of safe and reliable, maintenance-friendly, low-cost, high-carrying capacity, and suitable for assembly of larger and larger-weight components. a friction-type mobile roller track flexible assembly line. http://boserlgearreducer.com/product/list-zhiajiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: A typical structure assembly line for the speed-reducing machine