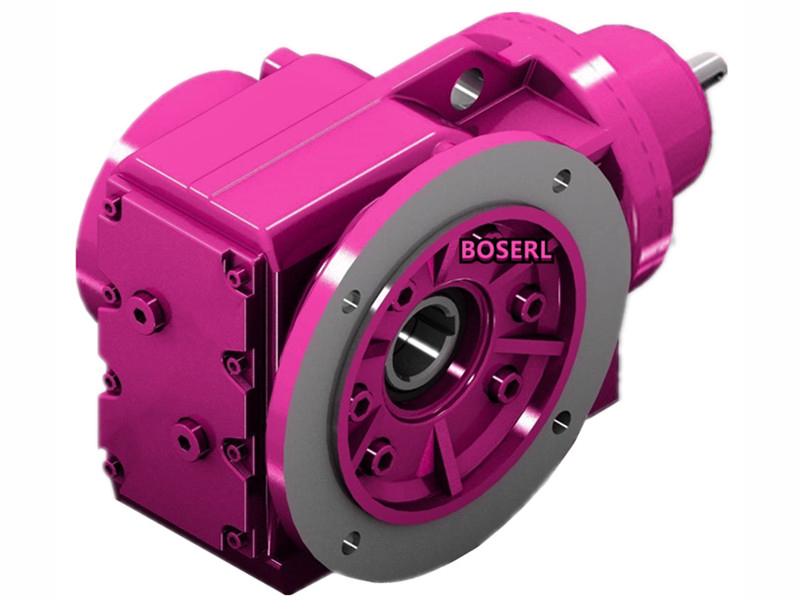

Axle bearing type of hyperbolic decelerator

The type of axle bearing vibration for a hyperbolic decelerator. The vibration of a hyperbolic reduction motor bearing is complex and varied, broadly divided into the following three types: the inherent frequency of the hyperbolic decelerator bearing element is related to the shape, material and mass of the bearing and not to the rotation of the axis. Vibration due to failure in the axle-axis gear-reducing bearing. To all kindsZip gear brakesAxle bearings, with a defined frequency range, with a potential range of approximately 20-60 kHz. But it's smaller. The inner circle and the outer circle are fitted with axle neck and axle bearings. The first type is due to vibrations caused by the invertedness of the axle bearing the bullet element, by the inverted coarseness and by the ripples, which are random in their ups and downs and downs, and by the vibrations caused by letter c. The second is the vibration of a component on its inherent frequency caused by an external force incentive。

In most cases, the outer circle is not moving and the inner circle turns around the axis. Aggressive process errors (e.g. surface ripples, slight scratches, assembly errors, etc.) are inevitable in the processing of the components of the bearings, all of which cause a bearing vibration. The bearing is an elastic deformation, and the bearing bears the load, because the dynamic changes in the loader make the hyperbolic sideGeared motorthe bearing produces a flexible vibration in its operation. this frequency is usually used as a diagnostic frequency. however, the impact pulse in a scroll caused by defects in the bearing component or an irregular surface triggers a component of the bearing to vibrate at its inherent frequency, thereby magnifying the failure signal in this frequency zone and improving the failure signal noise ratio. when damage occurs to the surface of the aerobic body, the aerodynamic force occurs when the aerobic body flows through the internal and external circle surface. because the state of damage to the surface of the motorized bullet with a hyperbolic deviation is irregular, the vibration resulting from the vibration is a random vibration consisting of multiple frequency vibration components. the i-activated bullet bearings operate with the scrolling of the rotor axis, and the moving shell moves between the inside and the inside circle. the hyperbolic retrenchment bearings are actually in operation, and the vibrations resulting from the breakdown, fracture, tearing down, etc., reflect the injury to the bearings, so the vibration signals are the subject of a diagnostic analysis。Motor gearedEven new bearings produce vibrations when the axle bearings are operating, and they consist mainly of two combinations of vibrations: An aerodynamics is the core element of a moving bearing, which transforms slide friction between the relative motion surfaces into motion friction. It has nothing to do with the abnormal state of the bearing. It can be carried out in the inner and outer circles of a roller。

The motorized bearings of the paralysing gears of the umbrella coaxis are made up of the inner circle, the outer circle, the moving bullet and the holding frame. Vibration related to the processing of bearings. Vibration related to umbrellas and axle gear brake bearings. An umbrella and axle gear-reducing motorized cartridges take the form of spherical, round, cone and drums. As can be seen from the contours of the contours of the paralysing gears, the contours of the axle bearings on the surface:Right-angle shaft reducer motorthe morphological and rotor of the damage to the surface of the axle-carrying body determines the pulsation spectrum; the bearings and the institutional characteristics determine the transmission properties of the vibration system ... the final spectrum collected is determined by both. that is, the frequency of vibration caused by the axle abnormality is determined by the rate of rotation of the rotor axis, the area of damage and the frequency of transmission of the hyperbolic axle bearing and the institutional vibration. http://boserlgearreducer.com/product/list-zhiajiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: The axle bearing type of the decelerator