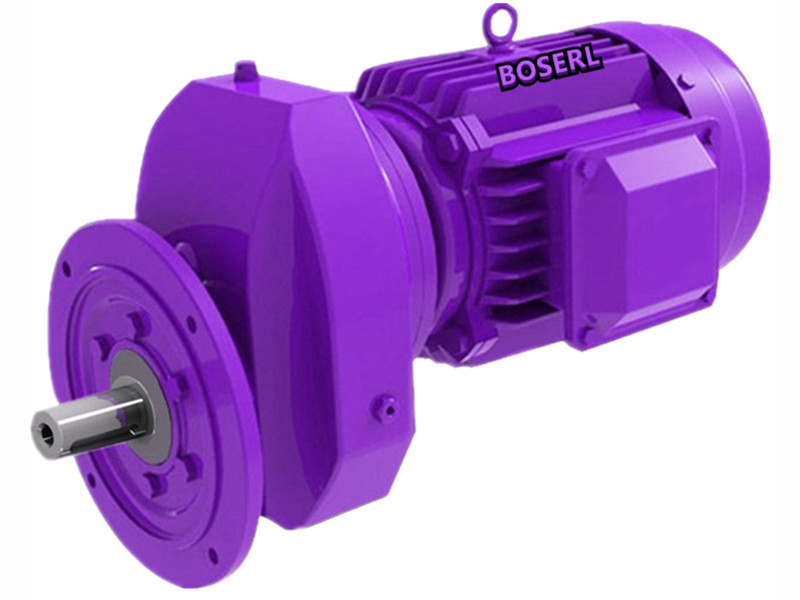

The axle seals of a combination of slow-down machines

The axle seal of the integration of thereducing power. In the course of the above-mentioned replacements, the bearing parts of the pumps must also be inspected. In the event of an increase in the above-mentioned leakage, it would be necessary to replace the axle sealing of the combined axle of the reduction machines. It is recommended that the relevant functional parameters be checked on schedule. The pump must be cooled to ambient temperature。Geared motorAn integrated circuit seal does not require any maintenance work. In the course of the maintenance work related to the integrated system of the slowing machine, attention is drawn to the following: Clockwise rotation: Progress Turns On Pressure; Opens the integrated pressure cap of the slowing machine and wrings the lock on the bolts. The stop-valve of the supply and export pipeline must be closed. Reload the pressure cover (don't forget to put the seal on). The axle seal was promised to have a very small leakage. Reverse clockwise rotation: lower the open pressure. The pressured nut in the filling box can be tightened only slightly so that the fillings in thereducing machine integrated during the operation of the machine can produce a light leak, which can help to diffuse the heat generated by friction. The necessary security measures for the integration ofreducing machines are required before the relevant dismantling exercises are conducted to ensure that no accidental start-up occurs. Check that thereducing power plant integrates all the tight screws, bolts and connections and, if necessary, re-heat them. Checking for the positive state of the joint axle and repairing the wear and tear of the elastic components associated with the integration of theimprovement motors。Motor gearedIntersections of integrated filling rings or jamming rings shall be staggered at approximately 90°, and the integration of slow machines shall be located at the end of the pressure cap at the end of the filling ring. In the event of leakage, replacement is necessary. If there are significant scratches on the axis, the axis must be replaced, otherwise the sealing of the new filling ring will be affected。

It can then adjust the bolts to set the opening pressure required by the spinning screw liner. RecommendedGear reducer and gearboxIntegrated pressure set value: approximately 10% higher than the working/operational pressure of the system. If there is a genuine need to update the filling box components, the axial bearings and sealed silent rings must be checked. Maintenance work related to the axle sealing of a combination ofreducing machines is limited to non-scheduled check for leakage. If the off-pressure valves need to adjust the open pressure of the off-pressure valves, follow the following steps: after the machine has been operating for a long period of time, if the combined leakage rate of the slower motors mentioned above is too rapid, the nut on the pressure cap of the filling tank can be tightened (i.e., rotated by one-sixth round) and then checked for the extent of the leak mentioned above. Care must be taken to break the filling ring along the axis and in the direction of the path, so that the ring can flow to and from the axis. For double or combined seals, the liquid position of the gill fluid in the container must be checked and filled as scheduled (if necessary). In the context of normal operation ofreducing motor integration, if thereducing machine integrated device is well utilised For slide media, Steimel gear pump time is not required to be maintained. Check if the pump is leaking (especially the position of the axle seal). If it is no longer possible to tighten the nut on the cap of the filling tank, an additional filling ring must be attached. In general, there's no need for changeMotoreducteurthe whole filling box component. the degree of integration of the monitoring devices (e.g., work-hour counters, pressure meters, pressure and temperature monitors, etc.) will depend on the corresponding norms for begging. http://boserlgearreducer.com/product/list-rxxiilijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: The axle seals of a combination of slow-down machines