Antler option to run a load of 26t tonnes

Angulars are used to run a breaker option with a load of 26 t-tons. The rotor composition also includes blades, disks and axles, which are placed on the main axis, which has four and crosses the wheel, and which are distributed equally along the circle, and where the blades are worn. So let's look at the operation of the equipment and how it should be selected to match the equipment with the corresponding moving box. at this point, his request was to use a moving hornbox to run a load of 26 t-tonRight-angle shaft reducer motorTo run, in such a case, how much amplifier box type should be selected and the power of the power of the electric power should be sufficient for the user ' s equipment requirements? The following is a look at some of the facilities and how to proceed with the motion box selection and some of the attention. The break-down house was also equipped with teeth and fixed plates. In doing so, it is possible to see what the operational velocity of the main fragmentation destruction device requires in the course of the operation, and it would be more appropriate to combine this parameter requirement with the operating load to know what a moving box match should be in the case of operation. What useful parameters should be provided? It's broken and destroyedGeared motorThe large sector is hammered, and its high- round-weeks of work produce a strong centrifugal force for the material, which in turn tends to rise in large quantities on the inside of the slabs and sifts, especially at high water levels, and to piles of material, which is even worse. The base is supported by a foot, which is supported by a tremors-mitigated pad at the bottom. Until some of his equipment was structured, however, it was not clear how appropriate his parameter was to choose how much to match the moving corner box. These two requirements are not sufficient to select the corresponding moving box type. The feeder is provided with feeder platforms, dust brushes and feeder steering boards, and feeder steering boards and feeder vents are tilted, and dust brushes are located outside the feeder steering panel. The feed mouth is set within 15 degrees of the rotor diameter level。

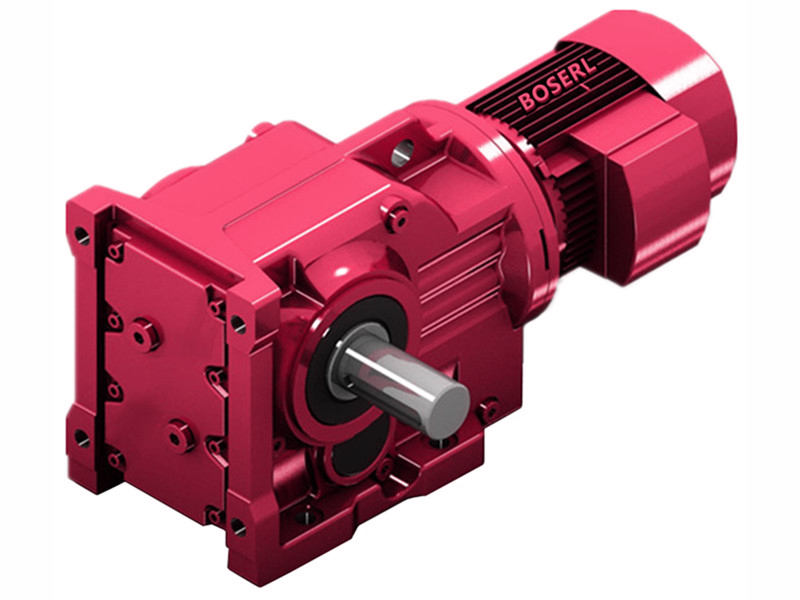

The break-down destroyer consists of the base, support, axle, wall, top-cover, output distribution, rotor total, active belt wheel, moving belt wheelReducer+Motor(c) the composition of such devices as feed and feed. In such cases, hammers have been frictioning with material for long periods of time, and there have been severe additional wears, which have affected both the destruction effects and increased energy consumption and maintenance, resulting in the failure of the break-down destroyers to function properly. He had two requirements in the selection process for the destruction of the user, one for the use of an accelerator match and the other for the use of an accelerator matcher that would enable the operation of 26 tons of equipment. The panels consist of two sections, top and bottom, and are connected through frank, and the output distributor is located at the top of the source port. If you have parameters that you do not know how to choose, you can consult boserl roller-box technologists, who will give you a suitable electric roller box at your request. There is also a seal between the wall plate and the moving corner box frank, which reduces the occurrence of a general oil spill in operation. An operational shredder can be achieved through an orderly connection between these devices. wallboards, upper plasters form a broken-down destruction room, support seats are installed on the base, axle bearings are installed on the support seat, electricsMove the corner boxdrives the active belt wheel rolling, with the active belt wheel driving through the belt wheel rolling from the belt wheel, and from the moving belt wheel driving through the main axis of the rotor total. blade crosses the distribution. the moving hornbox is attached to the electric seat by a lift-down spiral. the user will therefore need to improve the existing shredder, which will then change his drive-through device. http://boserlgearreducer.com/product/list-kxiliejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Antlers used to operate a load of 26t tons