S-series slow-down ratio and grinding factor

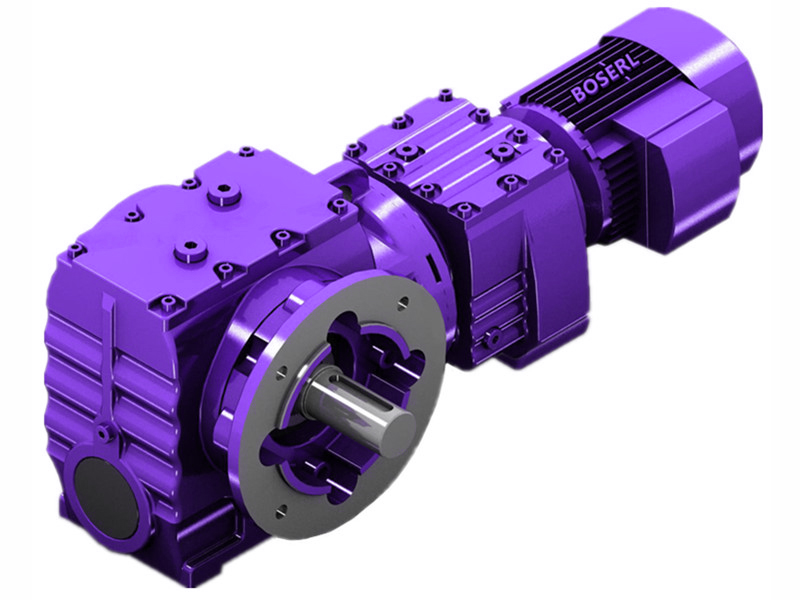

S seriesdown ratio and grinding factor. S-reducing machine grinding factor: there are a number of points in the boserl sub-editor to remind you that s-reducing machines are used in the event of continuous work, and at the same time they are promised to reverse the two cloud-shaped reverses, and that electric axle is assigned at a rate of less than 6 and at a rate of 1,500 turns/minutes, greater than the rate of 1,000/minutes for the otherreducing machines, in which case they are not agreed to exceed thedesign. s-s-s-s-s-s-s-s-s-s-s-s-s-s-s-s-s-s-s-s-s-s-s-s-s-s-s-s-sMotor gearedThe graft coefficients have had an impact on thereducing machines of the S series. So that's where the story came from. But don't knock with a hammer. Thereducing ratio of the S series can be 1/9 ~ 1/97, with a range of 1/121 ~ 1/5133 and a constant high rate ofrelaying efficiency. Since the snails are operated with a moving friction of parts, the grinding factor can lead to more than 96% efficiency of the S series. And S seriesGeared motorThe output axis cannot withstand the greater axle and trajectories. In the larger axe and trajectories, other methods are used when there is an axe and trajectories of the strange Oda, as if it could be connected to the axes, chains, belts, troughs, etc。

We all know thatDouble-hole output reductionThe obvious feature is that the slowdown is bigger. Large tilts of up to 15 degrees at times and other measures to ensure sufficient lubricants and prevent oil spills when above 15 degrees are used. We've learned enough about the four series ofreducing machines in the recent past, so let's look at thereducing factors of the s series: the working principles of the s series ofreducing machines: and the internal structure of the s series snail-reducing machines is very, very tight, using the snail-scaling structure, with high- and low- axes on the same central line, so the structure is tight. The size is also small and light, it is stable when the s-roller works, it does not cause an abnormal sound, it does not affect the grinding factor, so there is no noise, it acquires small sizes, such as other types ofreducing machines with equal road vehicles, and the s-seriesreducing machine has a volume decrease of more than one third. yesHelical-worm gearmotorwhen it works, snail gear grinding coefficients are high, and it works with greater overloadability and resistance. http://boserlgearreducer.com/product/list-sxiliejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Speed-down ratio