K-series speed-reducing machine cooling method

The k-series slowing machine cools. in addition, unlike axle-mounted fans, more interactive fan blade design options can be selected and can work on their own, and not related to the rotational direction and rotation of the cone gear axle, where necessary, for example, when summer temperatures are higher, additional cooling methods can be provided to achieve constant temperature control, which can be removed and cleaned without prejudiceDouble-polar slowing machineI don't know. an electric fan cooling method can replace axle fans and external oil-air heat exchangers, where a fan is installed on the k-seriesreducing box, with a steering panel that directs the gas flow along the cone gear-reducing machine and on both sides, and with the advantage that the electric fan has advanced the imprescriptibility of the input axis, improving the cooling effect and controlability, and, first, the parasol wheel input axis can be linked to other moving components, such as belt wheels, reversers, and hydraulic complications。

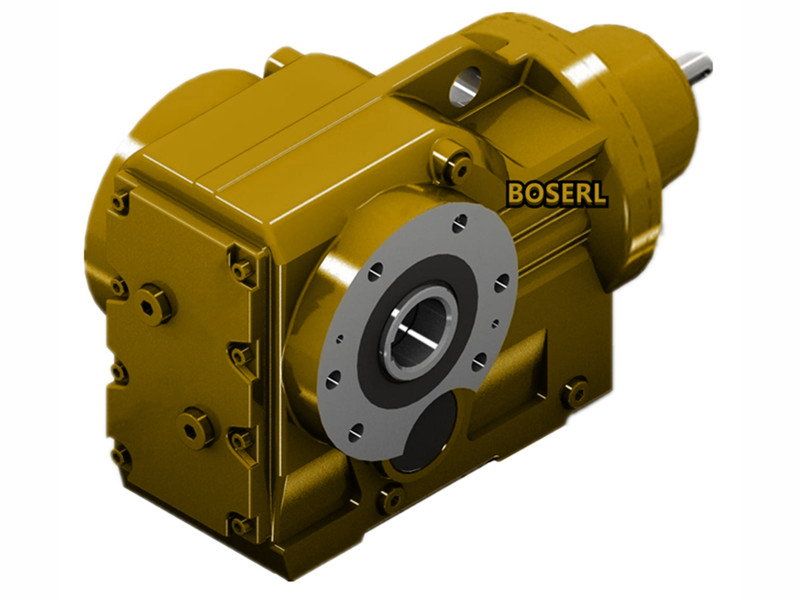

Because today's conic gearreducing machines bear high loads, the cone gearreducing gears produce high heat, which results in a reduced useful life of the k-series gear-reducing motors, the choice of a fair-way cooling method becomes the cone gearGeared motorImportant sectors of work. Air cooling takes the form of natural cooling, axle fan cooling, oil-air thermal exchangers and fans (external), the basic method - natural cooling - which conveys heat to nearby air using natural convection and radiation heat, but which often does not match the load used in today's drivers. As such, the tank temperature should be lower, so in special applications high reliability is required at 140-150of and additional capital or cooling units are required for larger transmission devices. Thermal power depends on the parameters (model, size, ratio, velocity, oil number and level, and cooling unit) of the cone gear reduction machine, the working environment (near temperature, air current, work cycle) and the promised temperature of the large tank. In the case of the g. O. T. O. S recommended by the g. O. O. A. , the life of the k. V. V. gear transfer and lubricant is defined。

Thermal power means that the k-seriesreducing machines can function continuously and do not exceed the specified high-power temperature of the tank, which is, or is greater than, the heat power required to perform well. The higher the temperature, the greater the heat power. it's closedMotor-gear reducerThe maintenance of appropriate oil temperatures is important to ensure the lifetime of the gears, and cooling becomes even more important in the long-term use of the cone gears, as improvements in the design, materials and manufacturing methods have resulted in the improvement of the mechanical power of the k-seriesreducing machines, all of which have resulted in a high load, as well as an increase in the heat of the moving devices。

Although 200 off is not recommended for temperature, in some cases it is possible to achieve a suitable cone gearreducing motor transmission feature, for which some cone gear-reducing machines use a high promise tank temperature of 220 off, but work beyond 200 offi (even under short-term conditions) reduces the lifetime of lubricant and contact seals, increases the wear of the k seriesreducing gears and axle surfaces and reduces these impacts to a level that requires accurate maintenance, with several cooling methods available for closed gear-reducing to advance their heat power, the basic methods of which are air cooling and water cooling. so, chooseDramatic gear brakeconsideration should be given not only to mechanical power but also to the corresponding cooling methods in order to maintain a certain thermal power. the air cooling method is described below. an alternative method of cooling is an air thermal exchanger of external oil, which is pumped to recycle the oil between the tank and the radiator, followed by an electrical fan to cool the radiator, which, in order for the oil to operate, will cool the radiator, while the heat exchanger, like the heat exchanger, will need to increase the area of the ground and lay out external pipes. http://boserlgearreducer.com/product/list-kxiliejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Slower cooler methods