Case of 73. 5 retrofits per minute for a side-axis slasher in series f

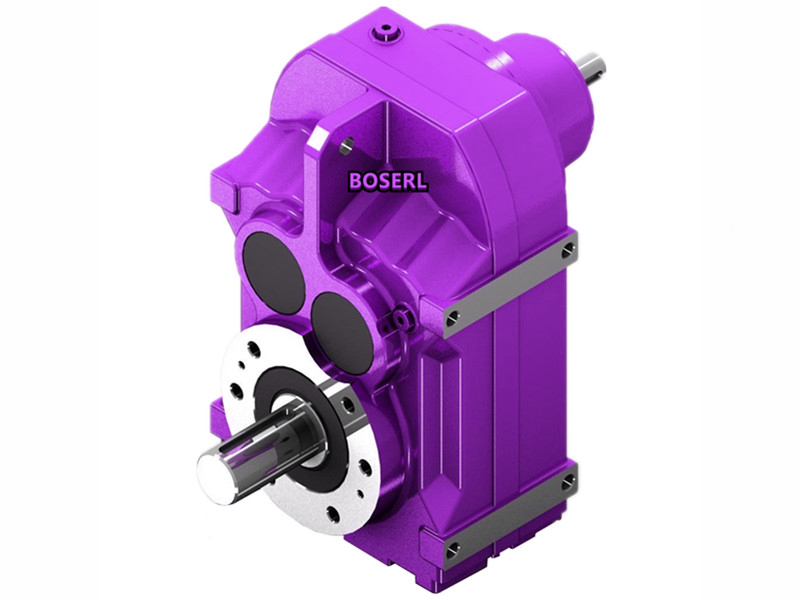

Series f parallel-axis slash gear reduction machine 73. 5 retrofits per minute. At this point, it is proposed to use a combination of f-frequency electric generators with a parallel-axis slash gear reduction machine, at which point the selected models are f27, f37, f57, f87, f107, f127. At the middle of the lower end of the shield, there is a assembly tank, and the middle of the stand is connected to a drum that matches the aggregate. working principle: by adding a substrate control body to the upper cauldron, and a turbo that is connected to the turbo on the turret by means of a slowing machine, the turret on the turret is used to control the amount of the material, which is used to reduce material wear and tear in transport, and the aggregates set at the lower end of the shield, which allow for the delivery of adhesive sectoral material to be dropped, recyclable in discharge drums to avoid volatilisation of material within the shield, and the parallel axial gears of the electric machine f seriesGeared motorThe wheel is carried back to the trajectories with a scratchboarded conveyor wheel and the trajectories move in the direction of the conveyor until they reach the point of the next cascading, the direction of the conveyor belt is reversed and the discharge is completed. In the user selection process, he wanted to use the f-series parallel-axis tilt gear-reducing machine to match the power machine, and how would it fit at this time? In the absence of further parameters, look at some details of the user's equipment. This is some of the details of the use by the user ' s equipment of a parallel axle gear brake in the f series. The material control apparatus consists of rotors, turrets and belts, which are connected by belts to the side gears of the f series of parallel axle gear reduction machines. On the other hand, there are different delivery units in the well-developed workshops to work on the various processes. In such a case, it is necessary to select the delivery machinery to be used according to the actual scene. users' transmitters include stubs, transmission orbits, axles, chains, conveyor belts, scratch panelsInduction Motor 3Ph, protective shield, upper plume, submersible control body, submersible plume, valves, rotors, wheels, belts, troughs, windows, panels, aggregates, drums, etc。

At production workshops in some industries, there is sometimes a need to configure machinery for actual production use. On monday, a user needs a scraper carrier to match it, and he needs an electric machine to combine it with a parallel-axis f-slash gear reduction machine, and at this point he needs an output running 73. 5 turns per minuteMotor gearedIf the f series is chosen for matching use, how much power should be selected for matching use would be more appropriate under such parameters? Let's see today some of the selections for the one-size machine using the f series of parallel-axis slash gears. But there are no detailed parameter drawings in the above-mentioned cases, so in these cases it is not easy to choose a detailed model to match it with his mechanical equipment, so let's look at the f-series parallel axle gear-reducing machine sample. The above models are compatible, and detailed configurations allow for the downloading of a sample of a side-axis slasher in the f series or for consulting with a boserl selected technical staff. An average of tatters in the middle of the rim. The wheel is attached to the axis, and the side of the wheel is connected to the axis by bolt. The middle position of the shield is connected to a window and the side of the window is checked for a more barrier. a fixed link at the upper end of the frame has a transmission orbit, a wheel is embedded at both ends of the transmission orbit, a chain is attached to the axle, a conveyor belt is attached to the middle of the wheel, an average cloth on the conveyor belt is scratched and an electrical f series is installed on the side of the frameGearbocThe main axle of the electric motor is connected to the axle by the parallel line of the F series, with a protective shield on the outer side of the transmission orbit, an upper cascading at one end, a material control unit at the middle of the cascading, a cascading at the other end and a valve at the lower end of the cascading. http://boserlgearreducer.com/product/list-fxiliijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: 73.5 retrofits per minute