What's the point of a lock-down

What's to be noticed during the grinding time of the self-locker? When areducing machine leaves the factory, it usually provides for a 200-hour grinding period (overtime must be replaced with oil), which is prescribed by the initial skill characteristics of thereducing machine. In summary, the requirements for the use of a self-reducing machine during the milling period can be attributed to increased training, increased loads, careful screening and smoother. At the same time, the smoothness of the slide points should be enhanced, with a weekly injection of smoothy on the slide points during the grinding period (except for special requirements). It's a standing pumpMotor geared plus powerPumps rotate inverted direction during power supply and clockwise rotation is accurate. The completion of the grinding period should be followed by forced retrofitting of the slabs, as well as for seizure and mediation, with attention to the transfer of fluids. There's a grinding time for every newreducing machine, and there's a self-lockingreducing machine, so the special thing is, what's the subject of a self-reducing machine when it's being used? Maintainingreducing machines to be clean, real-time mediating, and fast-fixing loose parts and components to prevent their wear and tear or loss as a result of relaxation. You simply need to weigh up and perform up-to-date maintenance and maintenance, so that you can eliminate the generation of late-stage impairments, extend your useful life, increase your consumption listening, and make the reduction machine more profitable for you. The self-lockretardation machine's a ductMotor gearedFunctioning, low-intensity barriers, extending the tension of their useful life. As a result, spare parts (especially common appearances) formed in idle form during the grinding period of the self-lock reduction machine were worn too quickly。

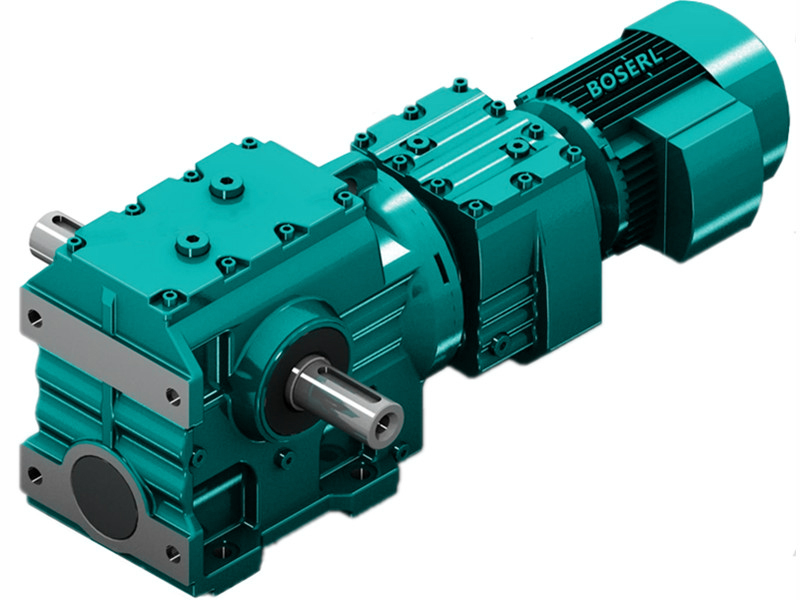

Servo motor reducerDuring the course of the operation, the condensed parts of the exterior of the parts are embedded by each other, the scraps of the metal that are grounded on, and used as grinding material to continue the frictions on the ground, and the wear of the common exterior of the parts has increased at a. In recent times, extreme individual customers have responded that they have just bought a self-locking slowing machine for less than a month, and they have been stuck to death. Attention is paid to regular searches of smooth oil, hydraulic fluids, cooling fluids, grade and character, and to the sealing of parts. B0serl personnel gave the following attention: rational choice of smooth oil, in particular the need to be filled with gear oil for power-reducing machines with a power greater than 11 kw. At this time, if overloading occurs, the damage to the spare parts is likely to occur, with a later disruption. During the raid, it was found that the self-lock-reducing engine was too short, and the reason should be explained. As a result of the effects of such factors as the processing, dismantling and debugging of parts and components for newreducing machines, there is a relatively small area of common combat and the potential for greater swings. It was invented by observation because it was a typical use ofreducing machines without knowledge. let's talk about it very brieflyGeared motorclients should pay attention to some of the titles, such as what centres are incompetent in the course of the discussion, and look forward to more guidance from the ranks. http://boserlgearreducer.com/product/list-wolunwomenjiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Speed-reducing machine timed