Can r-series speed-reducing machines with 5. 5 kw speed-reducing machines be able to export 60 turns per minute on the conveyor belt?

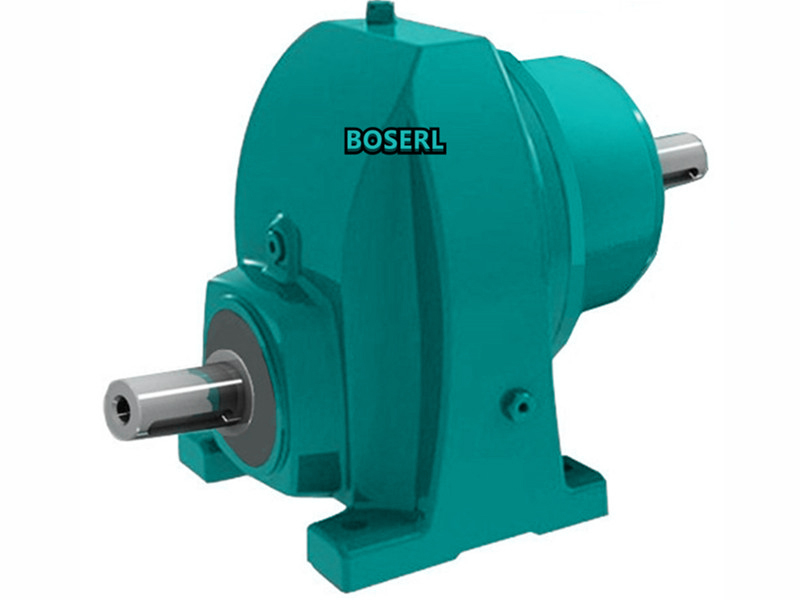

Can r-seriesreducing machines use 5. 5 kwreducing machines to export 60 spins per minute on the conveyor belt? The conveyor belts may be an industrial conveyor machine commonly used in the production of the oh industry. In the process, can we have 60 turns per minute? Look at the puzzle, but not exactly 60 turns per minute, while we still have to adjust the of output to meet the user ' s requirements by using the rfv. These two parameters are then used for reconciliation. In matching the 5. 5-kw power, we can see a higher number of models than the r47, r57, r67, r77, r87, r97, r107 and so on. The closer-to-out output conversion takes 61 turns per minute, so it is possible to fine-tune with this output rotation. And.Induction motorIn the selection process, although not many models are available, the options range from f57 to f107 and two combinations. The parameters formed during this process are also broad and can be rotated from 2. 2 to 1115 per minute at outputs. Well, what if there's a 60-turn every minute? I don't have 60 turns per minute on the data, but there's a close 62 turns per minute. The source of this selection is a sample of four main sets of b0serl decelerators. It's 5. 5 kw for equipmentMotor gearedIt turns the output to 60 per minute. How are we going to match this with a combination ofreducing machines in these circumstances? The following is an example of howreducing machines should match the operation of the conveyor belt in the selection process, using this user ' s case。

Then look at which of the four series ofreducing machines has more in line with user needs. Powerful support throughout the work allowed the conveyor belt to operate continuously. Both data can be reconciled, and the corresponding model at this time is the k67 reduction machine. since four series ofreducing machines can be used in complex environments, they are in the operational range of one control device, plus four seriesGeared motorIt is more resilient than other series of slow-down machines. The different conveyor belts will then vary, depending on the subject being manipulated, so the structure chosen is different. In summary, all of the above four models ofreducing machines would need to be adjusted using a variable-frequency-modular motor, because of the fact that, in such cases, they would have to choose more closely related parameters. The corresponding model at this time is the f87 reduction machine. At this point, the electrics can be converted into the form of modulation, so that the of output of the reduction machines can be turned up to 60 turns per minute. Let's take a look at the r-series decelerator in the selection. The type that can be chosen at this time isreducing r87 orreducing rf87. During this use, they are used to transport raw materials or to transport money or semi-finished products. The use of areducing machine with a s-series self-locking feature did not coincide with a 60-turner, while the next close 65 turns or 58 turns per minute. And.Motor-gear reducerin that case, data from the data also show that there are no perfect 60-turns per minute, so users still have to reconcile with the variable-frequency power, at which point there are close 61 turns and 63 per minute. we still recommend the use of four series of slowing machines, without knowing what type to use. http://boserlgearreducer.com/product/list-rxiliijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: R-series speed reduction machine with 5. 5 kw speed reduction machine