The case of a single-minute 82.5 rotation of the rotor gear reduction machine output

In the case of a single-minute 82.5 trans-select of the rotor gear reduction machine output. So let's look at some details of the user's equipment. How much power should be given to the rotor gear-reducing machine in order to be able to function with the user's slicer? So let's take a look at the swirling gear-reducing machine. Propulsive screw gearGeared motorThe electric power is connected to the control body, which controls the opening and closing of the motor, thus controlling the opening and closing of the propeller. But in these cases there are no detailed parameters, so it's not easy to choose a detailed model for matching, so let's look at the matching on the selected sample. The user's slicing machines are placed on the frame of the engine, the stylist, the rotor and the control bodies, which are connected to the schematic, stylist and cycling bodies, respectively, and control the stylish, stylist and chording. The control agency has a tactile manipulation interface, which changes parameters to make control more precise. Two sets of spiral poles are in reverse and multiple groups of spiral poles are present on the outer surface of the spiral pole. This is some of the cases in which the equipment of the user used an electricreducing machine. In the processing of some of the larger raw materials, slices are sometimes required. The control body is connected to the cutter, which controls the opening and closing of the cutter, thus controlling the opening and closing of the cutter. Sugar raw materials enter into the input box from the input point and drive the electric engine to roll the propeller and to mix the sugar raw materials. A user wanted to improve his equipment last week, and the requirement was to use itRight-angle shaft reducer motorFill the power with the output parameters required for his 82.5 rotation。

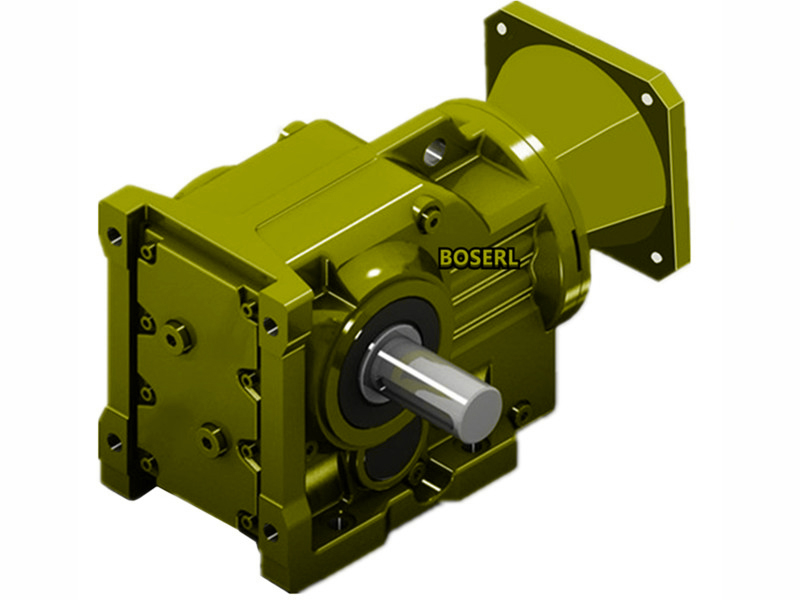

The rotor apparatus consists of a cutter, a cutter rotation axis with one end of the cutter, and a cutter electrician with a cutter rotation with the cutter rotation axisLevel-IIreducing machineAnd the case box, where there is a vent. Spiral thrusters have two sets of helix drive poles, and the propeller poles are aligned to the input point of the input box, the propellers are connected to one of them, both have gears and co-ordinated, and the propellers drive one set of helix drive poles to roll through the gear collage, thus driving the other. For the production plant, it is said that some large-scale mechanical equipment is needed to support their production. The detailed selection requires the user to look at the parameters requirements of its own equipment. The thrusters include feeder boxes, sugar raw materials set in the feeder boxes to be used in the direction of and to stir up broken screwdrivers from the input point of the input box to the output point of the input box, as well as a propeller screw gear gear-reducing machine to drive the propeller action, and a booster to be placed on the outer wall of the input box, which links the engine to the screwdriver. This set-up allows for two sets of spiral poles to roll, accelerate the mixing of sugar raw materials and improve their efficiency. At this point, the k37 and the k47 were matched with the vortex gear decelerator. The cutter rolls through the scissor rotation axle and rotates the cutter to cut the sugar tablets squeezed from the dropholes, the cutter and the moulds are placed in the dropbox, and the cut steps for the pieces are completed in the box and collected from the source. You can consult a boserl technologist or download a spectrotype of a screwdriver. on the user's choice of the corresponding power for his mechanical equipment andSpiral cone gear deceleratorin the selection process, his request was to use both combinations to satisfy the actual usage requirements of his equipment, and before more parameters were required, we needed to know the details of the user ' s equipment and then to choose the corresponding electric and rotor gear reduction model. http://boserlgearreducer.com/product/list-kxiliejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: 82.5 transpositions per minute