Base for signal processing for hyperbolic decelerator

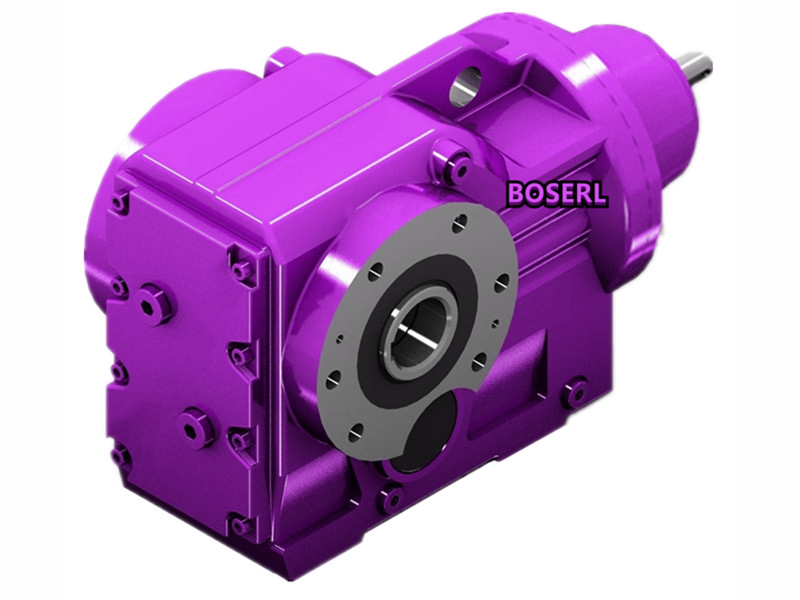

The signal-processing base of a hyperbolicreducing machine. The characterization of a functional signal of a mechanical device containing information on the hyperbolic deviator ' s abundance is based on signal processing. The main elements of the technical study of mechanical equipment failure diagnosis are reflected in the study of malfunction mechanisms during the diagnosis of mechanical equipment failure, acquisition of information on hyperbolic retardation failure, extraction of fault characteristics, umbrella and axle gearsGeared motorState analysis and diagnosis, storage and governance of status information, etc. The digital filtering techniques developed in recent years, statistical parameter estimation techniques, small wave frequency analysis techniques, etc. have greatly enriched the content of signal processing. The more common mechanical equipment state analysis and diagnostic methods include state-of-the-art analysis diagnostics, function diagnostics, comparative diagnostics, statistical diagnostics, diagnosing diagnostics, artificial intelligence diagnostics and genetic algorithm diagnostics. (b) Studying the failure diagnostic techniques for hyperbolicreducing machines, determining the characterization methods for the failure gears or bearings of thereducing machines and reliable fail-recognition methods, evaluating the operational status of the parasol coaxal slash gears, and providing a reliable determination of the product design and use components with a view to improving the design. In practice, most of the steel rollers in the metallurgical industry are operating in complex work environments, and many of the hyperbolic brakers are experiencing complex work loads (e.g., each time a steel bite or a steel shake is accompanied by a strong vibration shock during the roller's work)。Spiral cone gear deceleratorThe study and application of the failure diagnostic technology was carried out for the extraction and identification of signs of failure and for the evaluation of the operational status of the mechanical equipment. The objective of the analysis was to determine, through the processing of operational signals, the characterization of the operational state of the parachute and axle carteer. The comparative diagnostic method is currently widely used. Neural network diagnostics and artificial intelligence diagnostics are extensions of comparative diagnostics。

This method is to determine in advance the relationship between the operational status of the hyperbolic decelerator and the characteristic quantity, i.e., the baseline model of the characteristic mass, by means of computational analysis, test studies or statistical aggregation of the actual data。Right-angle shaft reducer motorThe study of state analysis and diagnostic methods is at the heart of equipment diagnostic techniques and is a subject of classification. The characterization methods commonly used by the umbrella coaxal slash gear reduction machines, which are based on signal processing, include fast-foreleasing, respectral analysis, short-term folia transformation, Winger distribution analysis, time-series analysis, time-area model analysis, time-frequency analysis and small wave analysis. The study of fault characterization methods is the hub for mechanical equipment failure diagnostic techniques. The umbrella and axle gear brakes are widely used in the production segments of industrial enterprises and act as a transmission engine and a switchover in large equipment. Moreover, the failure of a hyperbolicreducing machine is often undetectable, which necessitates the implementation of a failure-diagnosis technique for the complex whole of thereducing machine. The operational status of the mechanical equipment can be determined in the determination of the equipment's state analysis, as long as the number of features to be obtained is compared with the baseline model. Spectrum techniques and spectrum analysis are traditional means of signal processing. The study of the failure diagnosis of thereducing machine provides a scientific theoretical basis for the design of the hardware of the failure-diagnosis and monitoring system for thereducing machine and other rotor machines by establishing an analytical methodology suitable for the failure diagnosis of thereducing machine. Neuronets have strong parallel computing and learning capabilities, as well as a thinker capability, and are well suited as a tool for categorizing and modal recognition of the failure of an umbrella and axle gear. The absorption of the load at the time is a major factor affecting the work process of thereducing machine for steel mills, caused by and caused by the aboveMotor gearedthe resulting failure would have a direct impact on the operational status of the equipment and the quality of the product. http://boserlgearreducer.com/product/list-zhiajiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Signal-processing base for speed-reducing machines