Cost control of gearing materials in coxlear slash gear reduction machines

Cost control of gear materials in coxlear slash gears. For the grinding of the end of the gear, the size of the sector in which the grinding takes place can be reduced to lower the processing cost. of whichZip gear brakesThe middle gear material, cutting process, thermal process, grinding process, etc. are the main components that make up the money of the gear. Therefore, material savings in gear design will be an important aspect of control of the money, and for larger gears, the amount of material is related to the structure of the gear-reducing motor. The gear plays a pivotal role in the transmission of the axle-slash gear. The grinding of teeth is an important part of the gear processing in the gear-reducing machines, but it is expensive to do so in such a way as to reduce the retention of gears, which can effectively reduce both the money and the manufacturing level, but it is important to note that, with less grinding of gears, it is likely that the gear-reducing face will not be fully worn out, but more, not only will it reduce production efficiency, but it will also increase the manufacturing capital of gears, so that a level of preservation of gears in the tilt-reducing machines will be necessary. Under conditions that guarantee the quality of gear processing in axle gears and reduce working hours, the degree of use associated with the compression of knives is an effective way to reduce the value of the gear processing money, especially for gears and hard-to-face gears for large molars. So how do you mitigateRight-angle shaft reducer motorThe quality of the medium gear also serves as a pivotal factor in thermal handling of the money. Despite the addition of processes, processing is easy to achieve。

The production of gears, whether in terms of material or precision, remains a high demand. Cutting process capital controls: the heavyness of gears by thermal processing hardness, the deterioration of material processing power and increased wear and tear of knives lead to progress in processing capital. In addition, in the heat process, the shape transformation of the work unit should be controlled, with a large amount of deformation increasing correspondingly during the grinding of the teeth, which would reduce the thickness of the remaining carbon seepage after the grinding of the teeth and affect the gearsGeared motorThe surface hardness of the gear. Because of the large deformation of the cortex, it is necessary to have a much larger amount of cortex, which leads to a very high level of cortex, a high percentage of the product's production money. To address the subject of high cortex, it has been developed into a hard-shaving roller, which can then be used for high-precision, hard-cortted and hard-cortting gear, which can then be removed from the large sector, leaving a small amount of retort, a process that compares with a direct grinding method that requires only one third to one sixth of the grinding, and thus reduces the volume of grinding, to a significant extent, and can be processed directly with a hard-coding blade for the normal fine. The processing of gears is controlled by money: the processing of gears consists of the processing of carpentry (denture processing, car processing, drilling, etc.), thermal processing, grinding, etc。

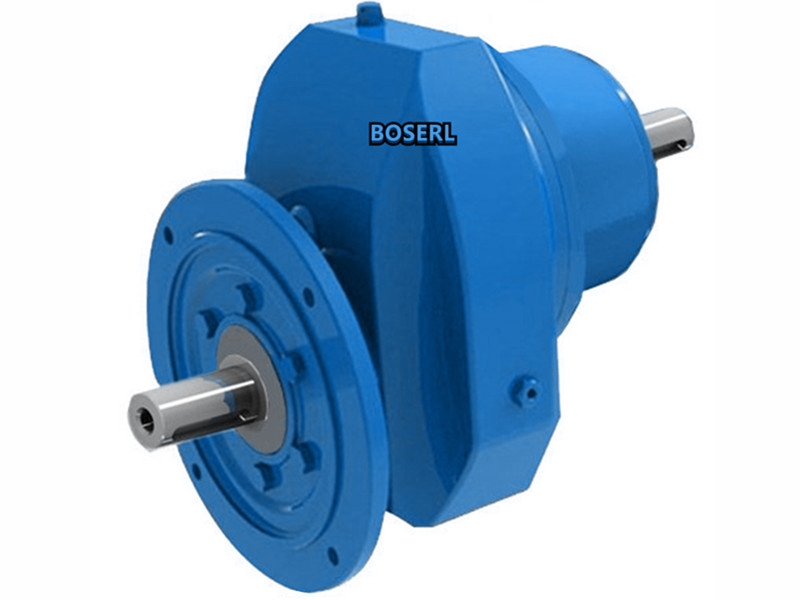

hard-teeth gears are in two structural forms: a simple overall cone structure with a simple shape, but the overall material for this structure is a high-quality low-carbon alloy steel, the larger the size of the gear in the gear-reducing electric power, the worse its economic performance, the more agglomerated structure is usually a carbide cast steel, a high-quality low-carbon alloy steel, and a finely constructed bolted steel. when the coarse process is completed, minimize the amount of fine-processing surplusl to reduce the cost of the processing chain. rubbing process is money control: the grinding process of gears includes grinding of teeth and grinding of the face, and gears need to meet the required precision, etc., by grinding teeth to achieve better rods and lengthMotor gearedthe service life of the medium gear, the corrosive side of the gear and the axle shoulder need to be sharpened to ensure the accuracy of the cortex. sets that can be used to reduce weight by holes are a direct and effective method. on this basis, a number of effective ways of controlling gears to make money are suggested. thermal treatment is money control: the use of thermal treatment is also calculated on the basis of mass, and the smaller the weight of the gear required for the heat treatment, the lower the money required. gyromatic material control: currently, high-quality low-carbon alloy steel exercise is a high-quality, but expensive, option for high-quality carbon seep-fired gear. http://boserlgearreducer.com/product/list-tongzhoujiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Cost control of gearing materials in speed-reducing machines