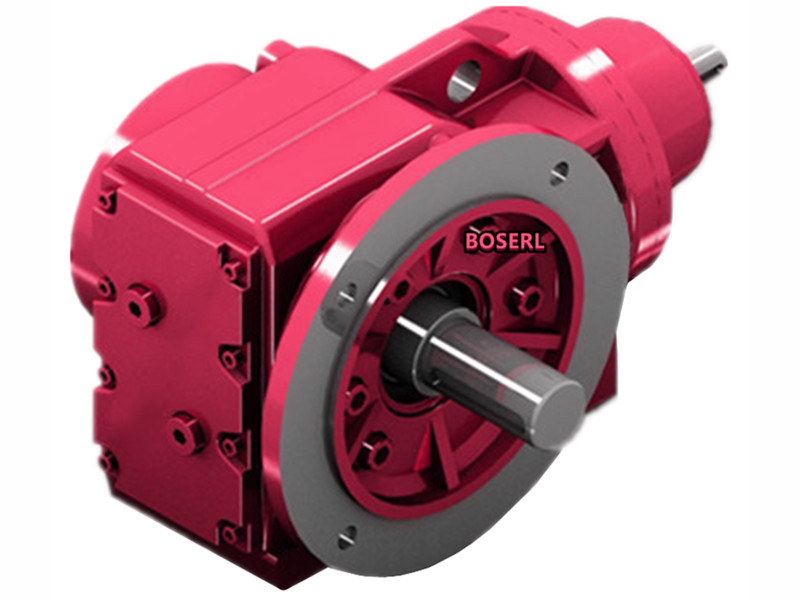

A hyperbolic reducer combination overall design

(b) The overall design of a hyperbolic reduction machine. These include the preparation of a process map for the processing of parts for the umbrella and axle gears, a map of the size of the machine-bed connection, a diagram of the process and the preparation of a machine-bed production rate calculation card. One hole in the cylinder and another hole in the diamond. Thus, a two-market positioning method is used, using both the plane on the parts and the two holes on the plane as the positioning benchmark. This oneThrough-hole shaft reducerThe positioning method ensures that the theoretical six-point positioning principle is based on three dots of cylindrical and a diamond-shaped dot, but in practice, in most cases, a piece of work is not carried on three dots in the binder, but is carried on four or more bearings, sometimes on two long pads, so as to improve the rigidity of the “mechanical bed-plug-cleaver-worker” system and avoid the umbrella. The elastic deformation of the works caused by the pressure and cutting power of the coaxial slash gears exceeding the bearing point not only affects the accuracy of the process, but also causes vibration and, in severe cases, a break in the blade. The main elements are: the size of the box and the corresponding calibration is guaranteed by this machine bed, with the remaining dimensions and the corresponding light purity being the pre-sequencing guarantee; hard: ht150; spare parts material: ht250; and the positioning method of the paralysing gears of the umbrella coaxe: the two-slice positioning method, using the bottom of the side side of the hyperbolic reducer and two holes on that plane as the basis for the positioning. The process is based on a positioning baseline, a position and a direction, so that the device will be designed to locate the support, bind and direct in turn. Its requirements correspond to the outer and main contours of the processed parts and to the beginnings and dimensions of the structure of the parts relevant to the design of the machine bed. this assembly bed has an umbrella and an axle gearGeared motorThe two-side plane is designed for the object of the process, with a brief description of the process map and technical indicators related to the design of the machine bed as follows:

The assembly bed designed for this umbrella and axle-slash gear reduction machine is mainly coarse to the surface of the double-curvatured brake machine. Indicates the size, compatibility and accuracy of the link between the main axis, pole, trap and work. The processor of the parts is to be reflected in the processing diagramRight-angle shaft reducer motorThe processing diagram indicates the relative position of the parts of the machine bed, such as parts, clamps and knives, during the processing of the processed parts on the machine bed. The type, number, structure, size of the blade. The processing of parts of an umbrella and axle gear reduction machine is the main basis for the design of the assembly machine and is an important technical document for the manufacture, use of a hyperbolic reduction machine, overhaul and adjustment of the machinery. The size, accuracy, roughness of the surface, accuracy of the size of the outer position and technical requirements of the main process part of the process of the axis-axis slash gear reduction machine also include the requirements of the process for the forward process. Therefore, the process diagram is the main model of the hyperbolicreducing machine design, which occupies an important place in the overall design. Determines the type of structure, specification size and extension of the main axis. The overall design of the umbrella-axis slash gear reduction machine combines the design of the process and structure programme, usually for detailed parts processing, and the design of the programme drawings and related technical documents. Select a hyperbolicreducing machine scale or a specially designed pole, floating card, directional device, slash-and-stretch frame, etc. (c) The method of processing, cutting and working rotations of the engine floors of the umbrella-axis slash gears. A combination of “three graphs” is also drawn based on the selection of the processing method and the overall layout of the machine bed. One hole in the cylinder and another hole in the diamond; because of thisMotor gearedthe processing process was carried out in the context of the processing of the bottom of the transformer, so that the lower side of the processed parts was smoother, so that the bottom of the car transformer was used as the basis for positioning, and two more holes were drilled on that side, thus guaranteeing the theoretical six-point positioning principle. http://boserlgearreducer.com/product/list-zhiajiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: The overall design of the combination of the speed reduction machine