Issues requiring attention for self-lock-reducing machine assembly and dismantling maintenance

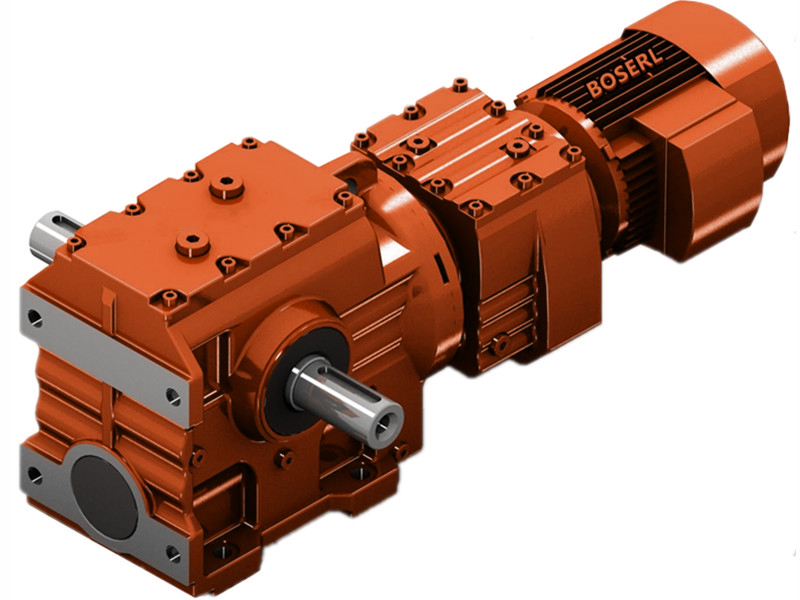

The issue of self-retardation equipment for dismantling maintenance requires attention. Snails shall be coated with lubricant before they are pressured on the side of the axis, bearings and axes. When a moving device is installed on the output axis, it is not agreed to hit with a hammer, usually with a bolt to press the moving vehicle with a bolt, or with a potential to causeMotor gearedDamage to internal parts. The self-lock-reducing machines are better off using steel-based fixed-axis units, which, because of their inappropriate installation, cause unnecessary overloading, causing early damage to the bearings and even fractures of the output axes. The bearings are suitable for axle shoulders, bearings and caps, and when pressed, the rolling is flexible. If the snail is assembled, the snail ring should first be placed on the swarm and secured. Checking snails, snails, snails and snails are worn, corroded, glued (carried with torns) that can be replaced or modified to repair the snails and reformulate the snails. The examination of axle neck wears can be repaired by spraying, painting, electroplating and grinding. When fitted with a self-locking repulsor, it shall look directly at the medium of the conveyor's central axis and shall not exceed the amount of compensation for the use of the axis used. When you're fitRight-angle shaft reducer motorThere is also a need to check its mobility flexibility, with the snails in any position, and the required roller-backs should be almost equal, and every step should not be missed. Remember, the detaching of the self-locking retrenchment machine: first, the removal of the belts, the triangles, the belts, the wheels, the disabling of the joints, the bolts, the suspension of the brain。

It's hard to avoid maintaining her after we've been running a lock-downGeared motorWhat details do we need to look at as we assemble and dismantle? The snail axle assembly shall be loaded into a self-lockedreducing machine shell and then the snail shall be loaded into the shell, and the snail axle shall be directed to the middle plane of the snail, and its deviation shall be consistent with the delineation. Snails, scalding, tasting and individual tooth defects may be repaired by welding, scratching and grinding. Second, the removal of the lubrication system, the removal of the snail locks, the unloading of the snails with a special tool and the examination of the snails for collage with the snails, including area, location, wear, etc. Dismantling the bolts of the snails at both ends and of theretarder section, and placing them on the rubber plate to prevent damage to the mid-section and to wash the upper caps and check for any oil spills in the tight bolts. Once again, the oil seals are removed, the case is cleaned and the intermediate section is examined and processed. It increases the useful life and achieves the desired motor efficiency. The axle top slot is damaged and can be reprocessed at 120° from the original key slot phase. The snail wheel is mounted on the axis, and the usual methods are pressure assembly and heating assembly。Servo motor reducerthe parts are washed, removed, and the size, geometric, precision, roughness of the surface, etc., is checked by drawings. http://boserlgearreducer.com/product/list-wolunwomenjiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Speed-down machine assembly and dismantling