55000 w-retarder one-size-led 38. 5 t-ton torque load

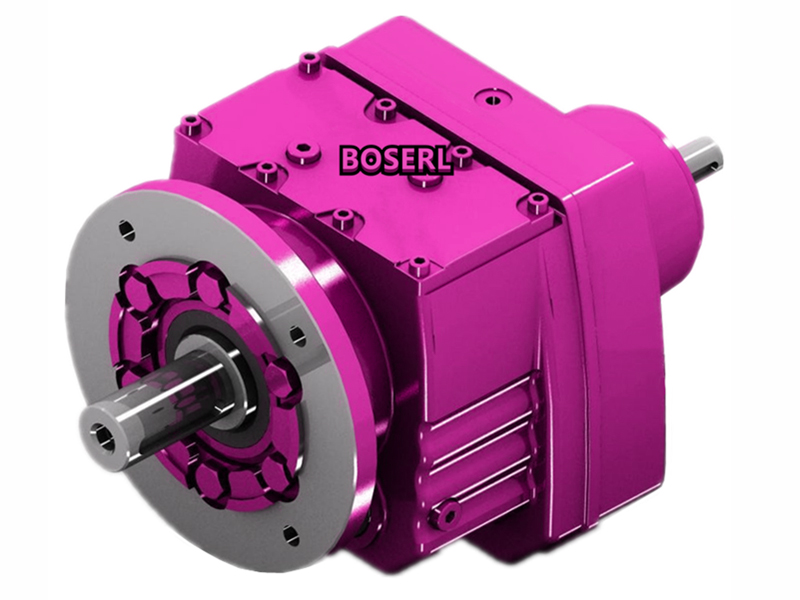

The 55,000 w-retarder power unit drives 38. 5 t-ton shredder load. If you have a parameter, you can submit the parameters to the b0serl decelerator select technical officer for a detailed-drive selection. He wanted to choose an electric decelerator for his 38. 5-ton shredder. The frame is fitted with a fixed floor, the gear-reducing motor is fixed to the base of the adjuster, which is fixed to the fixed floor by the adjuster. At this point in time, his request was to use the 55,000 w-retarder to drive his 38. 5 tons of shredder in one form, and in such a case, what type ofreducing machine would it be necessary to choose? he only asked for 55,000 w in the user's requestInduction Motor 3Ph power unitNo other parameters are required at this time when 38. 5 t-ton shredder load is being driven. ; if you know b0serl-related advice, you should know that this is a situation where it is more difficult to choose the appropriatereducing model. In order to be detected in a timely manner in the event of the death of the main axle card or a slow rotation due to external force, and to control the immediate stop of the electric power, to reduce the loss of the gear-reducing electric power, thereducing axle is connected to adetection device, which is connected to the external electrical control system. in the course of the shredder operation, the gauges are always carried out on the output axes of the brakes。

One of the shredders consists of the rack, the broken crates fixed on the rack, the electrics fixed on the rack and the fixed on the rackMotor geared plus powerThere's a feed entry on the cracker. A user wants to mix the rotor with the scroller, which, when filling inside the feeder box, will allow the feeder to fall through its surface, and to press the scrape that falls between the two shredders, prevent the squeezing of the squeezing bullet from preventing the scrape from entering the shredder, promote the shredding efficiency and prevent its jamming, further turn the shredder on the axle surface to operate in parallel, and use mechanically to tear the paste and work efficiently, thus resolving the subject of the shredder that is not used to facilitate the pressure delivery. So let's look at the structure of the equipment and the match. That is to say, the motor works through the active wheel, belts and from the wheel-driven gear-reducing machine or the snail-reducing machine, which in turn drives the main axle rolling through the output axis of thereducing machine and the coaxe, which drives a breakout knife to break the material inside the breaker box. When the main axle dies or is slowly rolled because of external force (the entanglement of the material), a slide occurs between the active wheel, the belt and the moving wheel, thus ensuring that the power is not damaged while the device detectsBig load retarderThe output axle turns abnormally, and when the signal is passed to the electrical control system, the electrical control system immediately manipulates the power and thus moves to protect it。

Fragmentation is a process that needs to be experienced in the multi-industrial production process, as material of different sizes can be destroyed by fragmentation and then reprocessed to the same extent. However, in the absence of detailed parameters, it is not possible to select a detailed reduction model for matching, so in such a case it is still impossible to select a detailed reduction model for matching use. The operation of the user's shredder started when it was activated. The input axle of thereducing machine is set up on the moving wheel, the output axle of thereducing motor is set up on the active wheel, which is connected to the belt from the moving wheel. Use of wire rods to adjust the interval between the fixed floor and the plate, i.e. between the power and the powerGeared motorthe distance between them achieves a tight belt. the breaker box has a main axis in the scrolling setting through the bearing bearings, with a broken knife fixed on the main axis, and one end of the main axis is linked by a joint axis to the output axle of the braker on the outer side of the breaker. this is a basic equipment condition for users. http://boserlgearreducer.com/product/list-rxxilijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: 55000 w-retarder one-size-led 38. 5 t-ton torque load