The case of a side-axis brake for slashers with slag loads of 23. 5 t

The case of a side-axis brake for slashers with tilt gear on a load of 23. 5 t. scatterers, including shells, fixed teeth, shredded, mobile tooth shredded and dusted shells, pneumatic pipes, wind machines, aggregates and driveThree-phase variant powerreducing machineand so on. Slag machines are used for disposal in some industries, in which case the different slag machines are of different sizes, so that they are designed to match the corresponding driver to the actual operation. After long periods of use, the slag tends to accumulate thick ash, and when the slag accumulates too thick, it has an impact on the fire power, so a more thorough ash clean-up of the slag needs to be carried out, and after the slag is removed, as well as a recovery of the slag, but there is a lot of ash in the slag, which is not easily disposed of, and which is usually dealt with in a way that is more time-consuming and labour-intensive. The user's requirements do not specify which electric tilt gear parallel axle brakes are used for matching use, so this could be either a tilt gear parallel axle or a snail snailGeared motorFor matching use, then the choice of an axle axle axle-discharger to be used on the slag, at which point we need to match the device to meet the user ' s parameter requirements and installation requirements according to the technical realities. When a user was selected recently, he asked for 23.5 tons of slag machines to be operated using a tilt gear parallel axle brake, in which case the user did not know how much of the slasher parallel axle axle to match, so let's look at the details of the match。

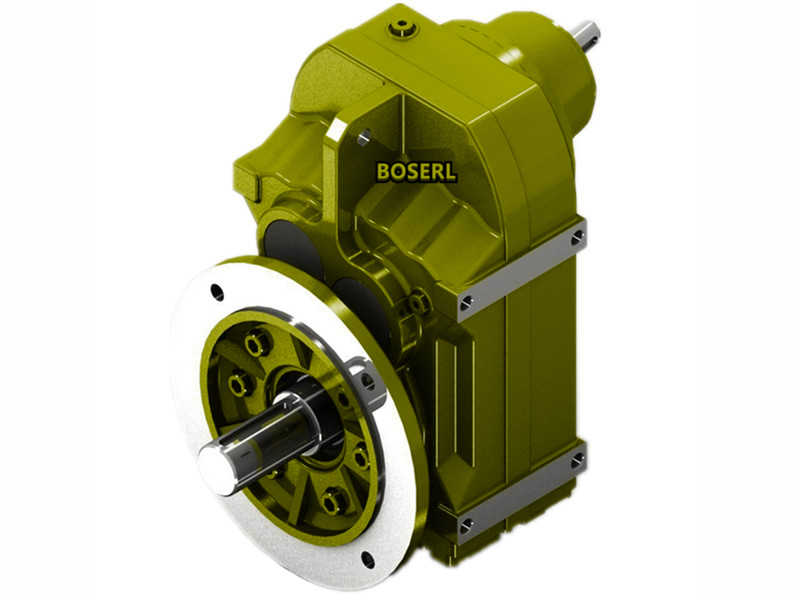

In boilers with a evaporation of not more than 0.5 tonnes/hour, manual slag is used, and specialized slag removal equipment is generally used, classified by method as mechanical slag removal, hydro slag removal and force ash removal; the slag removal equipment for power stations is one of the essential equipment for power station equipment, following the increasing capacity of the boilers, the use of low-quality, high-grey boilers and the increasing emissions of ash, for example, a 200 MW unit of 670t/h lignite boiler, with a daily discharge of approximately 150-200 tonnes of ash, which makes the slag removal of boilers increasingly important. If you have parameters, you can consult BOSERLMotor gearedSelective technologists match you to the respective mechanic's head with the electric slasher parallel. The amount of day treatment required by the user is 23.5 tonnes, and at this time the specially large turret axle axle axle is not required to match the device's length for use, and after talking, we choose to use the trisonic axle to match the turret axle axle for operation with the slag axle. Different parameters used in different environments require that there be a difference between the type of side-axis brakes chosen for the engine slasher, so that the choice of the type is based on the actual situation, and that the side-axis brakes are capable of meeting the need for installation. The grey water in the upper trough of the drosser is not easily integrated into the bearings of the installed structure of the suspension wheel. It also means that, in such cases, protection is to be applied to the side-axis brakes of the tilt gear, which, because of the special nature of the environment, are to be progressiveGearbocthe level of protection made it possible to provide appropriate protection to the side-axis brakes during use. http://boserlgearreducer.com/product/list-pingxzoujiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: The brakes are used on a load of 23. 5 t slag