The beer factory's brewing equipment is a screwdriver gear-reducing machine

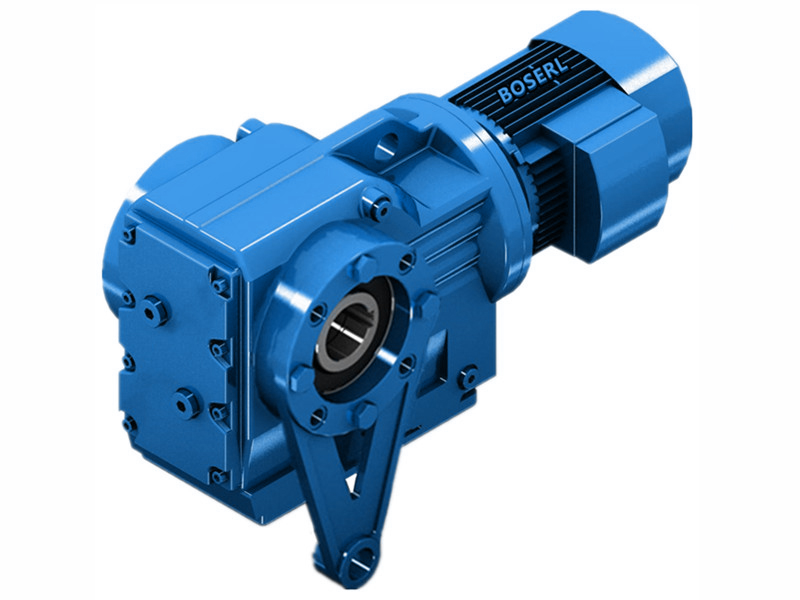

The beer factory's brewing equipment is a screwdriver gear decelerator. This is the processGearbocThe converted surface became very resistant to scratching, as it was six to seven times harder than the original aluminium alloy. A new 18,000-square-foot beer factory was recently opened on the outskirts of madison, wisconsin, which is the leading contracted beer factory in the midwest. Through the upgrading of the brewing equipment of previous generations and well-established staff, they are not only involved in the brewing process, but also provide comprehensive advice and strategy development on how to succeed in the artisanal brewing community. The decentralization control vfd eliminates the need for expensive central control cabinets and expensive wiring, thus saving sustainable capital, reducing installation time and minimizing manual capital and very cheap system modifications and upgrades. The contract beer factory not only helped to reduce the cost of the house and to eliminate the high cost of equipment purchased at the new craft beer factory, but it was also environmentally attractive to bring production closer to all demand locations. It's wonderful chemistry, erosion and grinding. k107 slow down and new typeSpiral cone gear deceleratorCommunication vector drive series are designed to be used in distributed control scaling up。

As the demand for refined beer continues to grow, beer brewers have begun to shift to contract beer factories, a cost-effective alternative brewery that can help them enter a rapidly growing market for refined beer. The availability of decentralized or centralized vfd control is another advantage of the b0serl solution. two series according to requestMotor gearedAll have chosen to use hollow holes, installed by frank, and equipped with energy-efficient generators. The brewing equipment is equipped with a b0serlk-series spiral gear reduction machine with five horsepower motors to roll the mixer roller in the beer equipment, while the f-series parallel axle gear reduction machine with five horsepower motors rotates the mixer in the beer equipment. Sprinting in brewing equipment, the b0serl transmission programme, using a sealed surface conversion system, provides an economically efficient, light quantitative replacement for stainless steel gear brakes. Through a revolutionary process, the shell and parts of the aluminum alloy reduction agent were electro-catalyzed, leading to the transformation of the molecular surface. Installation of the drive on the head of the membrane will replace the wire box of the membrane to create a fully integrated combination of memorizers/drivers. every seriesGeared motorthere are unique strengths and strengths. http://boserlgearreducer.com/product/list-kxiliejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Brewery equipment, screwdriver gear brakes