An effective way to reduce the grinder's load with a low-speed, big-twirl

An effective way to reduce the grinding machine ' s load with a low-, high- twister. Maintenance and equipment spare parts are not of high qualityServo motor reducerThe most direct impact of this is the efficiency of its use, as well as the most direct impact of its life, and we have conducted rigorous inspection and surveillance of its parts, all of which have been assembled with high-quality accessories, which have greatly improved its maintenance effectiveness. So we're only able to do it from the angle, and there's a positive ratio between the power of the power of the electric and the frequency of the frequency. We've been doing a lot of experiments here, and we've come to the conclusion that, in this case, if the frequency of the frequency is within the range of 33 Hz-40 HzLow-, big-twirlIt is a state that can achieve the desired. And if the output of the frequency transformer is on top of 40Hz, it will be more than 40 HzLow-, big-twirlThe load increases to a certain extent, and in this case the temperature of the body increases significantly and there is a more severe vibration. As the core of the millLow-, big-twirlFollow-up maintenance and installation are also important. With respect to the topic of the large amount of water available in the working environment, we have set up a special shield for the low-, high-twirl-reducing machine, which, by using it to a certain extent, can isolate water and milling from the shield, thus effectively improving the working environment of the mill. if the output of the frequency transformer is less than 33hzBig load retarderThe output power would be relatively small and, in this case, there would be some difficulty in starting the grinder。

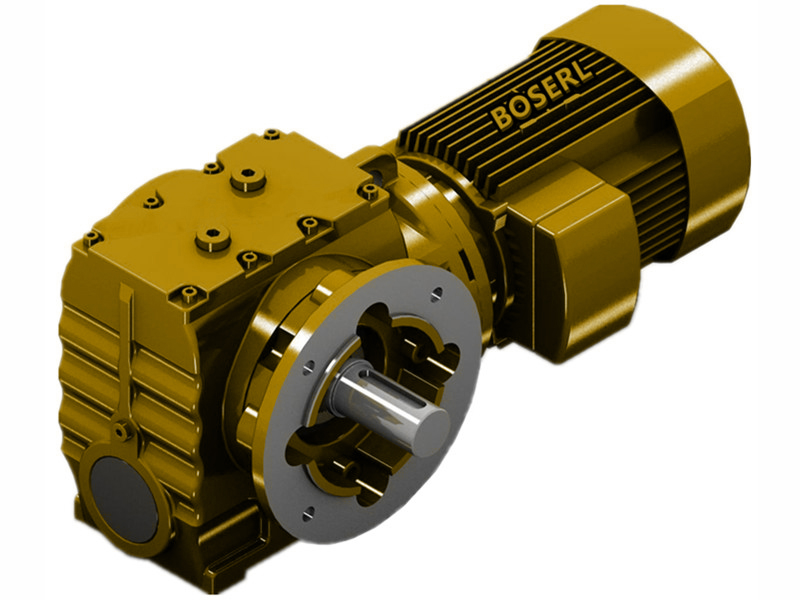

Use of grinder transfer devices in an electronic processorLow-, big-twirlthe grinder has a relatively high rate of rotation, and there are eight places on the grinder, and each has a weight of about 40 kg, precisely because of this high weight, which is likely to hold on to itLow- big twistGeared motorThe useful life has some impact. We performed some comparative analysis with the addition to the frequency setup and before it was added, and found that the output frequency was within 33hz-40hz at a power of about 66-80% without adding to the frequency power. at the same time, install accuracyLow-, big-twirlits operational effects, its useful life, and especially its powerLow-, big-twirl. And the grinding machine's working environment, where there is a large amount of water and grinding slurry in the vicinity, makes it relatively difficult to work in this environmentLow-, big-twirlThere could be some erosion and wear, while lubricated oils were deteriorating at a fast pace, further acceleratingLow-, big-twirlAnd if the frequency of the transformer drops to a certain extent, the power of the power of the power of the machine dropsLow-, big-twirlthe load is effectively reduced. due to limitations in the production process premises, this method of weight reduction is excluded. to that end, we have stepped up technical training for staff and have acquired tools such as stifling, which has significantly improved by keeping the coaxial error within 0.2 mmLow-, big-twirlThe operating premise. As a result, one party is faced with a degree of awareness of the requirements of the process; On the other hand, it's abatedGear reducer and gearboxthe loads have resulted in significant savings in electricity and more desirable economic benefits. http://boserlgearreducer.com/product/list-sfxiliejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Effectively lower mills with low-speed, big-twirl-reducing