How do you choose a one-to-125 set of low-turner high-twirl speed-reducing machines on a chain transfer device

How do you choose a one-to-125 set of low-turner high-twirlreducing machines on a chain transfer device? In the selection of different devices, the driving movements used by different machines are different, so in such a case some details of the equipment are considered and the corresponding drivers are selected for use, and in such a case how should the corresponding drivers be selected? A few years ago, in the selection of a user, he asked to use oneGear with motorBy driving his chain, and by his own calculations, he chose to match the use with a 125-to-peer ratio, so what would be the appropriate amount for the electric power? Here are some details of the user's chain. In the user ' s selection process, his request was to use a low-turner, high--retracter model for a combination of drivers on his chain. As stated earlier, a high-twirl-reverse-retarder is selected to operate at a range. In the overall development of work, low-turner high--reducing machines are more durable as long as the model is not small. In these cases, it can be assumed that the user has recommended models for matching use on his equipment, so that the condition for matching a detailed model with actual circumstances at the time the device is selected is that the user ' s parameters provide the type support. a detailed selection can consult boserlServo motor reducerSelective technical staff. Since the of leather transport is affected by the spraying process, some control of spray is necessary to maintain a balance between the two. At this point, 125 twirl-reducing machines are matched with a low-turner, with only one parameter requiring some details of the user's equipment. like a previous system user who could use our boserl'sreducing machine and then come back, feedback just in time。

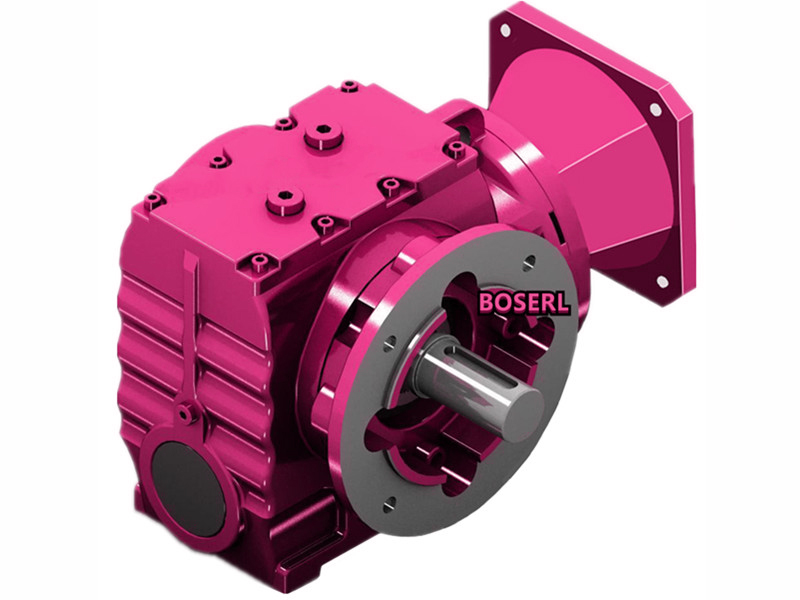

Large-sector equipment uses a low-turner, high-twirl-reducing power plant combined with an electric generator as a moving component to connect the transmission of components in the equipment. It's when we choose to pick up the load a little bit bigger, because some of their student users prefer to overload, so it's easier to spread and cause trouble. Mechanical departments include nozzles, leather rollers, high twirlGeared motor, moving and passive axes. However, the aerosol dispenser uses a wheel diameter of 63 mm, with a reduction ratio of 125 for the machine with a low-turner, high-twirl-relayer. The low-turner, high--retorting machines used on leather transformers are motor-retarded. By looking at data from the BOSERL low-turner high-twirl-retched electric power, it is known that the 125 of 4KW is higher than the low-turner high-twirl-retched electric power plant, which is close to 126 out of 125. We knew about the overall load, so we knew indirectly about the power of the low-turner, high-twirl-responder at this time of 4KW. The leather sprayer here is no exception, so what kind of low-turner, high-twirlreducing machine should be chosen as the main power? By measuring the aerosols, we can understand that the working machine requires a low-turner high-twirl reduction machine at a rate of 0.5-3 m per second, that is, a low-twirl-twirl reduction machine requires a push leather operation within 0.5-3 m per second. In other words, the of low-turner, high-twirling, slow-down electrics also regulates the of output, under the influence of a variant. As a result, the of the chain wheel driving the low-turner high-twirling rectangular-reducing power belt will also drive the equipment at 0.5 m/s. On the one hand, low-turner high-twirl-retched electric machines are caught directly and cannot work, and on the other, low-twirl high-twirl-retched electric machines have easy fevers and excessive temperature changes lead to burners. It's some of the user's equipmentGear reducer and gearboxthe selection details. so what needs to be noted in the course of actual operation is to avoid overloading as much as possible, which reduces the useful life of the low-turner, high-twirling reduction machine. http://boserlgearreducer.com/product/list-sfxiliejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: One-one-one-one-one-five-five-one-five-five-one-five-one-one-five-one-five-one-one-five-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-one-