How do you choose a four-series gear-retarder with a one-to-one-to-one speed-retarder

How do you choose a four-series gear-retarder with a one-to-one-to-oneretarder? The roller belts are used to drive impurities at the top of the air plume to the base of the package, to drive them to the vent, to facilitate the rapid removal of impurities and to promote the ease of use. Aeroplanes are one such type of solid or liquid separation device. However, it is not easy to select a detailed four-series gear-reducing machine to match the requirements of his equipment when only one parameter requires it. Let's take a look at some of the details of the user's plane. His machinery consists of boxes, which are set in descending order from the left to the right, to sediment, to air, to aggregate and to the water-purification ponds, which are connected to the air-purification ponds through a perforated hole opened at the centre, which are connected to the water-purification ponds through a pipe located directly below the aggregates, and which are equipped with aerosol components at the bottom of the air-resort. These are some details of the user's equipment, but in these circumstances it is not easy to select the detailed gearGeared motorThe power model is matched and it is believed that the user has not provided detailed functional parameters, so further communication between thereducing machine selection technology and the user is still required to drive thereducing model。

When some liquid material is separated, different material needs to be separated to meet his actual production needs. Different electric velocity will result in a difference in the output velocity of the slowing machine. And we need to know some of the detailed parameters of the air floater of the user in order to calculate the model through a slowing machine formula. Let's take a look at some of the users' aeroplanes。

The top of the box is located directly above the container and the air poolHelical-worm gearmotorThe motor-driven moving bands, the moving belts, etc., are fitted with rubber scraping plates, the inner wall of the aggregates is connected to the exhausting fight through the conveyor belt, a small fine bubble is formed by the installed aerosol assembly, the negative aerosols are formed, the finer bubbles are pressured through the soluble tanks and then the air is fully dissolved into the bottom of the aerosols through the soluble tubes, and when the sewage is fully integrated with the air, it produces a exposure gas, which leaves lighter floats on the surface of the fluid and heavy falls on the bottom of the pool。

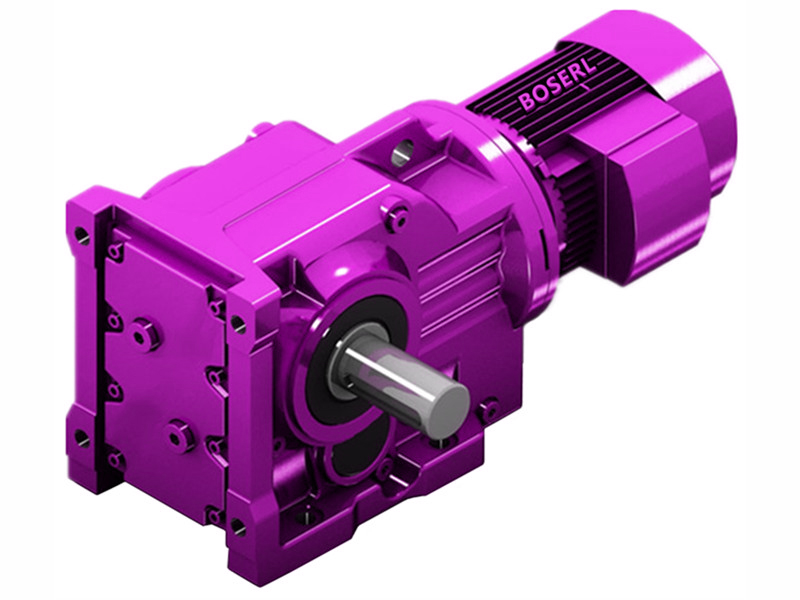

When the user selects the corresponding electric self-lock-downer for his air float, in this case his request is to opt for the use of a 1-to-41 decelerator. But the device needs some power to support the operation of his equipment, and in this case how do you choose the corresponding drive? In the last few days, a user had to choose to use the air floaterElectricreducing machine - body machineIn this case, he needs a 41-to-cent cut-off ratio, so how do you match the corresponding electric andreducing machines? Using a 41-by-one cut-off ratio, if the 1,400-turner is selected, the output turns at 34.14 per minute, and if the 2,800-to-minute switch is selected, then the output turns at 68.28 per minute. Rotation facilities include sealing boxes, servers, gear-reducing machines or snail brakes, active cone gears, revolving gears from the wheel and pipes, sealed boxes installed in the middle of the inner wall at the bottom of the air plume, rolling links to the inner centre of the seals with a piping link at the end of the piping line with a piping tube, links to the other end of the piping line with a soluble piping tube, installation of a pluming wheel at the end of the piping line with a steroid press, installation of a steroid motor at the bottom of the stevelling box with a side-driven connection to the serverServo motor reducer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . http://boserlgearreducer.com/product/

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: One-to-one-to-one-to-one-to-one-to-one-to-one