How do you choose a stand-by speed-reducing machine for 1:45 on a sludge dryer

How do you choose a stand-onreducing machine for 1:45? However, during the user selection process, he had only one requirement for areducing ratio, and it was not easy to select the correspondingreducing model at that time. The treatment of waste material at the end of production requires different treatments depending on the material. But he didn't know how much power he used and how muchreducing it would match his equipment, so he consulted under the circumstancesGeared motorSelective technical staff selects the appropriate model for use to meet the detailed requirements of his equipment. How would it fit in such a situation?

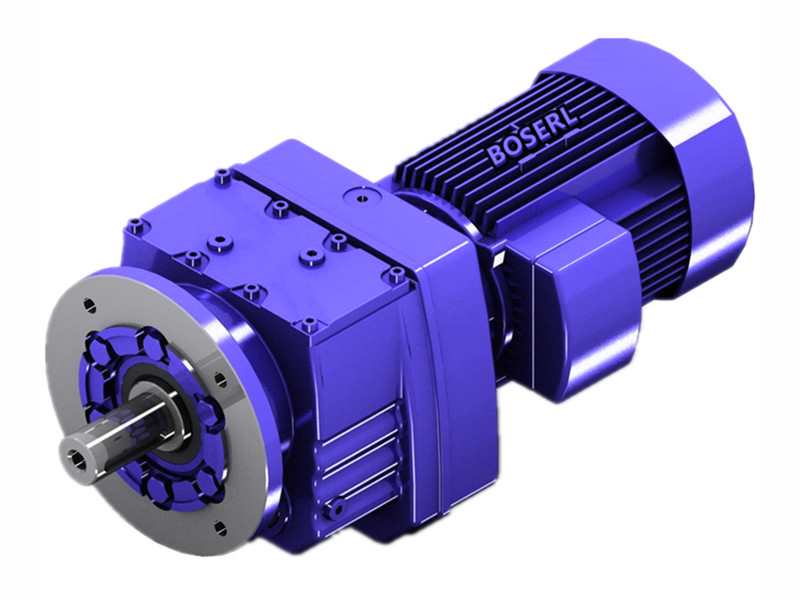

The storage warehouse is a ladder structure with both upper and lower teeth, and the storage warehouse is presented with a small structure with lower teeth at the upper and lower teeth, and the storage warehouse is connected to the cut-out particle box. It is therefore necessary to know the details of the user's equipment to select the corresponding electric andreducing machines. The storage warehouse of the user ' s device is placed on the exterior of the dryer, the strip-making unit is placed on the dryer and the strip-making unit is located directly below the storage warehouse. The storage base is set on the upper end of the slicing particle box, the drive-reducing machine is fixed on the side of the storage unit - the outer wall, and the gear is drivenInduction motorThe re-axis and the sub-axis are connected, and the sub-axis are set on the storage core through the bearings. For example, some sludges need to be dryed and then released when used. In the selection of a user a short time ago, his request was to use an electric reduction machine as the main driver on a sludge dryer. At this point in time, the user will need to communicate with the server-selector technologist to understand the requirements for matching the electrics and the slowing machine model to meet his equipment, so the user will need to inherit to communicate with theselect technologist to understand some of the parameters and then determine the model

Select to use on different devicesReducer+MotorThe use needs to match the corresponding model to the actual situation to meet the day-to-day operational requirements. The component oars contain a connector pole, and the one end of the connector is fixed on the outer wall of the distribution axis, and the component oars are set on the end of the line that connects to the wide segment axis, and the component oars are rectangular. A mix drive consists of a mixer-drive motor, a gear-driver or a snail-drive-driver, gear and gear, a mix-drive-driver anddrive connection, adrive and gear connection, the said gears and gear rods combined, and a ramp-drive connection of gears and gears and two symmetry-setd mixers, respectively. Anticipated particle-drives include strip-drive motors, brakes, gear gears and gears, strip-drive-drive motors anddrive connections, another set of brakes and gears, gears and gear rods, and cogs and two symmetrical axes, respectively. The mix drive is connected to the mixer, the cut-up particle drive is connected to the split axis, and the storage is located directly above the centre of the symmetrical mixer. In the course of his communication with thereducing technical staff, his request was to use a one-to-45reducing machine combined with an electric machine to satisfy his sludge dryer. This is some of the details of the user's equipment, where it is not easy to determine the model without detailed parameters, so in such a case the user is required to set the parameters of the deviceServo motor reducermodel determined. a group of substrate oars fixed on the outer wall of the substrate. the storage warehouse consists of a storage warehouse, a motor-reducing machine, a fraction axis and a component-group oar. cut-out granules are rectangular structures, two symmetrical mixers, two symmetrically set split axes and two symmetrically set copper combs are set in the direction of the length of the strangulation box. http://boserlgearreducer.com/product/list-rfxiliijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: 1:45 45 = 1 1:45 速 速 速 速 速 速 电 电 电 电 电 电 电 电 电 电 电 电 电 电 电 电 电 电 电 电 电 电 电 电 电 电 电 电 电 电 减 电 电 电 减 减 电 速 电 速 速 电 电 电