How do you choose the parallel axle speed reduction machine 1:50 on the cold curver

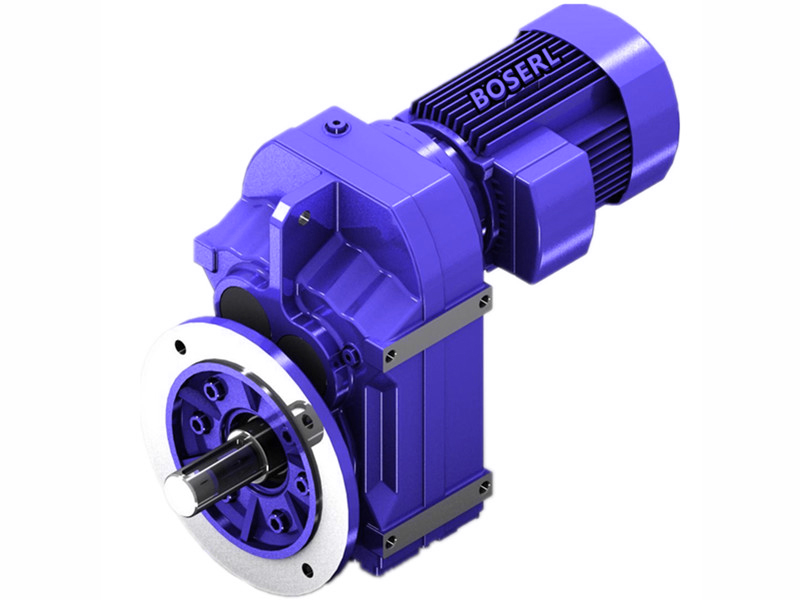

How do you choose the parallel axle reduction machine 1:50 on the cold curver? However, in communicating with users, his request was to use a 50-by-50reducing device, and what parameters could be used in such a situation to satisfy the 50-by-50 requirement? In the absence of other parameters, look at some details of the user's equipment. In the selection of a user in a short time ago, one user requested to use an electric generatorGeared motorUsing his equipment, but he did not know how large the power decelerator model was to be used to match the actual usage requirements of his equipment, so that in such cases the matching of the power and the reduction model was to be performed on the basis of the actual circumstances. the boserl decelerator selector technician, in the case you are given a choice, will match your proposal for a real, serviceablereducing machine with the actual operational parameters。

Or you can download a sample of thereducing machine to see how the detailed parameters match, and the plate moves to the left and is processed in the cold curver. User ControlGear motorsThe output axis scrolls around the clock, thus allowing the feeder box to move left, allowing the plate to match the input position of the cooler to the drive transfer device used on different devices, and the details are analysed to select the corresponding driver for use. The plates are processed through this device into the cold curver, and inter-mechanical work is carried out using a motor-drive-driven transmission device. the user turns on the power and controls the f-series decelerator that is connected to the power, or the output axle of the snail brake, which rolls back the clockwise of the output axle and drives the feeder to the right through the rotor and rail, thus enabling the lower side of the dent on the right side of the input box to contact the scrolled plate。

When the user selects the corresponding electric andreducing model for his cold bend, then the electric andMotor gearedThe model is different. The plate moves to the left, which, by force of friction, is able to drive the directional scroll, which operates through the cone gear and gear-driven conveyor, and the motor-drived conveyor, which allows the hairbrush to be moved, and the brushbrush to be cleaned and dirty to be washed down. In such cases, it is not known how large the motor-reducing machine chosen should be used by thereducing machine in order to operate his equipment, so it is necessary for the user to learn more about his equipment and to determine the model to be adequate for the operation of his equipment. In the process of processing some of the steel, he needed to process it with some of the devices similar to the bending machines. The transfer of the plate to the left would allow the scrape to scrape down such dirty things as the dust attached to the bottom of the plate, while the bottom of the right side, which would open the door, would scrape down such dirty things as the glued dust attached to the top of the plate, at the same time. The left side of the user ' s device is a cold curver, the right side is a roller, the user rolls a tight bolt so that the tight bolt is loose, the user is able to roll the feeder box and then adjust the angle of the feeder to the angle of the hand-roller, and when the adjustor ' s angle is completed, the user tightens the tight bolt, which in turn binds the feeder. So let's look at the details of the user's equipment today, and then look at the coolerInduction Motor 3Ph motor-formit's time to pay attention to something. http://boserlgearreducer.com/product/list-pingxzoujiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: 1:50 50 = 1 = 1 = 50 = 1 = 50 = a = 50 = a = 50 = r = r = r = r = r = r