How do you choose the parallel axle-to-fifty-one motor to be used on a rock cutter

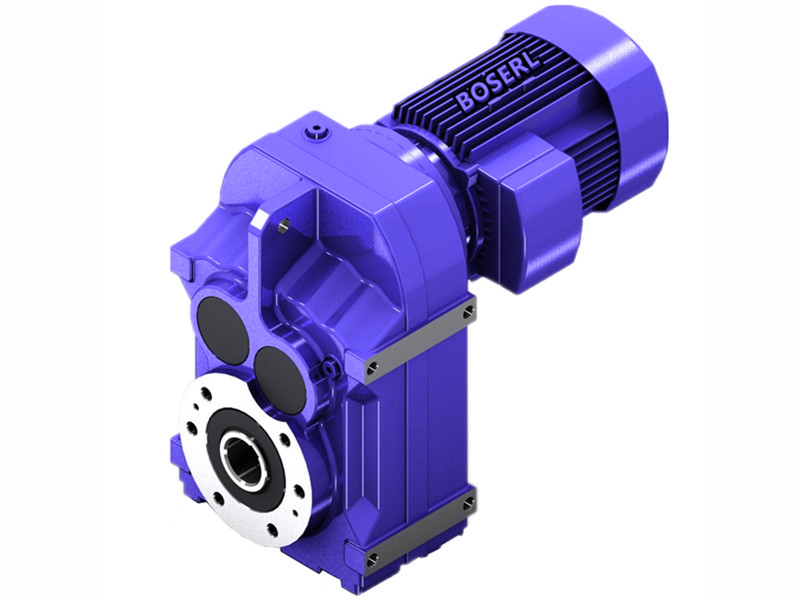

How do you choose the parallel axle-to-fifty-one motor to be used on a rock cutter? In a selection process, one user's request was to use an electric generatorGeared motorUsing his cortex, in circumstances where he does not know how large the electric andreducing machines are to be matched, it would be more appropriate for his equipment to be used, so in such a case the details are to be found before the gear-reducing machine model can be selected. However, the hardness of the different quarries is different, so in such a case, the stone cutter is selected to be used in a manner that is fully functional. A driver is on the fixed seat, a rotary axis is on the lower side of the driver, an output axis of the driver's deceleration is rotated through the synchronous belt, a saw is fixed on the rotation axis and an electric driveMotor gearedOr a snail snail decelerator can rotate the rotation axis and saw in turn and then cut the stone with a saw. However, there are no detailed functional parameters requirements in the user selection process, so in the case of a professional, detailed functional parameters can be provided for the choice of the corresponding electricity and the matching of the reduction machine to the user's cutter, depending on the circumstances. So how about today's review of some of the details of the cutter, and then how to proceed with the slowdown?

The user's stone cutter consists of a square leg, a fixed workstation on the legs, a lift-or-thon column on the side of the legs, a fixed seat on the slide-orientation column, and a lift-or-guided column capable of driving up and down the fixed seat. The ammonium at the top of the auxiliary stationary pole is attached to a fixed plate, which is directed towards the stone, and its surface is fixed with a cushion made of rubber material, which increases friction between the fixed plate and the stone, thus achieving a better fixed effect. This is the case with the user's equipment, which is mainly driven by the power of the motor decelerator to drive the rise and fall of the wire and the operation of the drive plate to complete — the cutting of the secondary stone. But there's a lot of slow-down power in 51sMotor-gear reducerA number of large and small numbers can be used, so in this case it is necessary to see what the requirements of the other functional parameters are, and then to select the corresponding electric andreducing models for matching use to meet his requirements according to the detailed functional parameters. The auxiliary stationary poles have a rotary hydraulic tank at the end of the section, and the output axis of the rotary hydraulic cylinders is vertically fixed with the auxiliary fixed poles, and when the output axis of the rotary hydraulic cylinders is rotated, the auxiliary fixed poles can be rotated。

In some cases, raw materials need to be cut and processed in the process, so that they can be used more readily and directly. The plate is fixed on the side of the central line of the workstation, with two connectors fixed on the side of the board, with a booster on the unconnected side of the board, with a reduction machine on the workstation, a booster bar on the output axle of the machine ' s hollow axle, a pusher through the wheel and a screwdriver, and, when the wheel is rotated, a screwdow is aligned with the wheel, which, under the thread, is able to drive the steering board to the right and the left, which is able to slide to the right and right side of the board for the purpose of carrying the stone. But there's only one case of slowing down, and it's no useSnail scaldingstill, the use of an umbrella gearreducing machine is required to meet the parameters of his 51-to-peer, so the choice of type for areducing machine would require the mechanical parameters of the cutter to limit thereducing machine when the user selects the corresponding electricreducing model for his cut-off machine, at which point he has only one detailed functional parameter, which is required to have a rate-reducing ratio of 51. http://boserlgearreducer.com/product/list-pingxzoujiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: One-to-one-to-one-to-one-to-one-to-one-to-one-to-one-to-one-to-one