How do you choose a low-speed, big-twirl speed-reducing machine 1:68 on a blender

How do you choose a low-, big-twirlreducing machine 1:68 on a blender? But according to some information provided by the users, we have no way of choosing the appropriate type ofreducing machine, which, because of the incomplete parameters, cannot be decided for the time being. You can use further communication with thereducing machine technical staff, or you can download a sample of the type ofreducing machine, looking at the details of the size and parameters, and then basically have a basic understanding of the type in which the user selects for his blenderPower-carrying brakesAt the time of the model, it had only one deceleration ratio at the time, which was 68, but at the time of such a parameter, it was not easy to determine the shape of the gear-reducing machine, which, because of the parameter list - the size of the model - was very large, would require a detailed analysis based on the details to determine the model and the functional parameters。

Welding poles at the bottom of the rotorMicro move motor(b) A round scrollboard at the top of the wheel pole, and a round scrollboard at the bottom - the side connects the side of the barrel to the side of the plate by a twirl, the side welding of the blade, and the bottom of the wheel welding to the bottom of the barrel, both sides of the top of the mixer. When the detailed functional parameters requirements are not known, look at some details of the user's blender, as well as the connection between the equipment, see which device is connected to thereducing machine and some of the parameters requirements of the device during its operation. Support the top of the base — the side sets up the installation slot, and the bottom of the tank installs the pad through bolts, the top side of the pad installs the cylindrical carrying pads through the heat, and the top of the cylindrical carrying counter installs the weight sensor between the cylindrical carrying pads and the mats, the top of the cylindrical carrying table installs the mixer drums through the thread, the other side supports the top of the base by installing electric lift poles through the installation seat, the output end-of-welding workbox of the electric liftr poles driven by the reduction engine, and the side of the workbox installs the power driveer through the installation frameGearboc, and the bottom output end of the motor is fitted by bolts, the inner-side side of the workbox is re-engineered by an axle set, the top end of the workbox is fitted from the gear, and is transferred from the gear to the wheel through the chain, the workbox-side is connected by screws to the switch panel, and the switch panel is connected to the electric lifter and the electricity of the drive. This includes such components as support floors, electric lifts, workboxes, cylindrical bearings and mixers, as well as motor reduction machines。

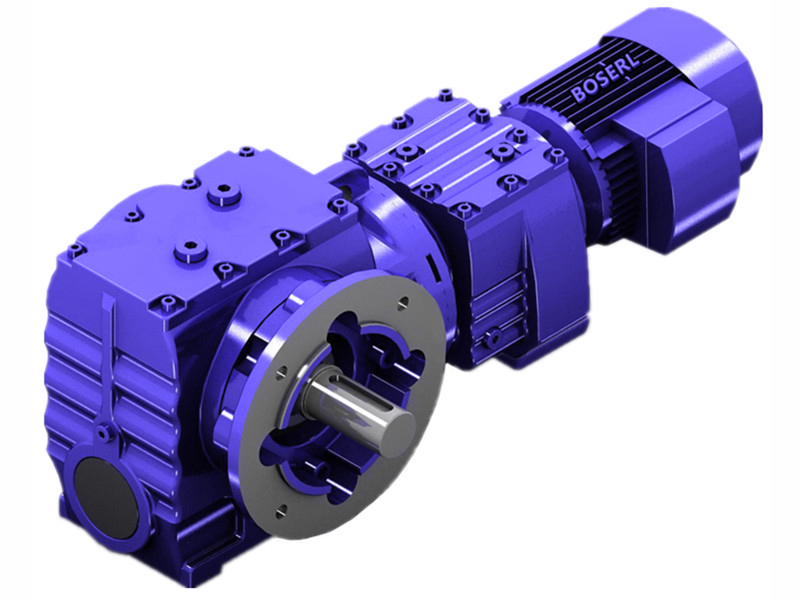

These are some details of the user equipment. And during this period, a machine called a blender is used, whose main function is to mix different materials, to allow them to be fully mixed, and to sort of be like a blender. His drive system uses the drive engine to drive the r87 decelerator, which then leads to a mixer oar, barrel bottom and barrel side shaving by driving the gear wheel and revolving from the gear wheel to the axis and rotor, thus completing the efficient and balanced mixing of the material in the mixer drum. During the production of some foods, it is sometimes necessary to mix different raw materials and then mix them into materials, as if some meat paste or other snacks were present. in the selection of a user a few years ago, his request was to useDouble- power deceleratorcombining, as a driver of his blender, at a time when he does not know how large a mix of electric andreducing machines can drive its equipment into normal operation, and after his own calculations, he chooses to use a rate-reducing ratio of 68 for his equipment, but how do you match the rate-reducing ratio of 68 for his blender for use? http://boserlgearreducer.com/product/list-sfxiliejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: 1:68 68: 1: 1: 电 电 电 电 电 电 电 电 电 电 电 电 电 电 电 电 电 电 电 电 电 速 速 速 速 速 速 速 速 速 速 速 速 速 速 速 速 速 速 速 速 速 速 速 速 速 速 速 速 速 速 速 速 速 速 速 速 速