5. 9kw/5900w power model size of s scalders

5. 9 kw/5900w type of motor should be equipped with a scalding machine. The introspective device is used to drive a one-dimensional exercise at the workstation through a series of power transmissions to achieve the introduction of tyres. Axis one is mainly a support for silk bars. Track 2 and the cylinder are installed on the workstation, and track 2 provides guidance and support for the mobile clamp, and the cylinder provides power and undisturbed grips to the mobile clamp. turboBae has a self-lockerA turn-start is being carried out by rolling silk bars through the movement of a convulsor, so that the nut movement, the nut and the workstation are driven to the movement, thus achieving the effect of cutting tires. The active wheel is connected to the moving belt from the moving wheel. A user's equipment requires a power supplyS scalding machineAs a drive-motion device on his tire cutter, he asked to use 5. 9 kwS scalding machineI don't know how much to use at this timeS scalding machineThe model would be more appropriate. Tyre cutting can cut used tyres into small blocks, facilitating storage, transport and recycling. Connecting the wheel with the cutting device and transmitting the power to the cutting device. Move the clamps forward with the push of cylinder I and work with the two fixed columns to tighten the tyres to ensure that they are installed. The position of the cylinders three-modulated wheel three keeps the cutting line in a state of tightness and achieves high- movement by a combination of wheel one, wheel two and wheel three. If your device needs to select a driver, you can be consulted. Rapid tyre fractures can be achieved through cross-cutting across sectors to achieve their intended effect. Drive Axis II connects the wheel one with the wheel from the belt, enhances the transfer of track and drives the wheel one to roll. Then let's see the tire cutter todayS snailGeared motorSelect some of the situations。

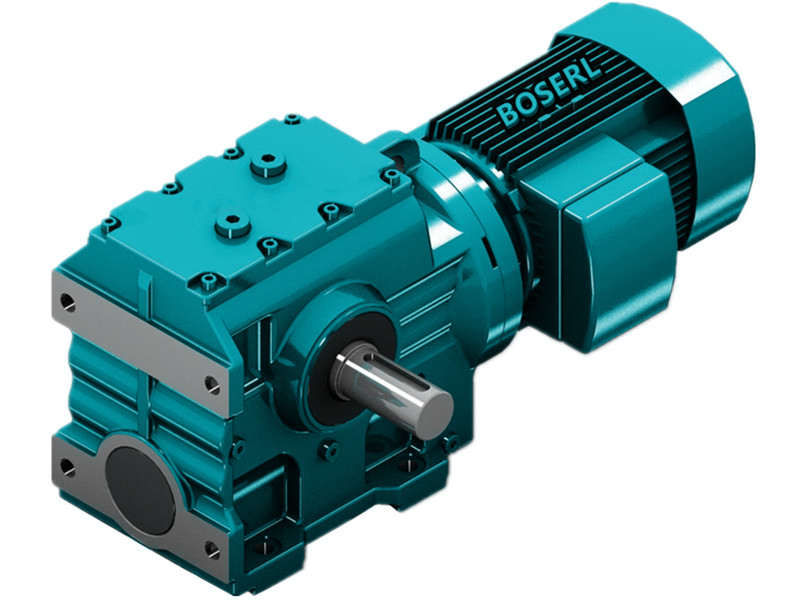

Users' cutters include delivery devices, fixtures, transmission devices, cutting devices and protective shields. It is not easy to select a detailed model for matching without more parameters, so look at some details of the user's equipment. One end of the transfer axis is connected to the electric gearbox two through the axis two and the other end is connected to the active belt wheel。S scalding machineA reverse can drive the workstation backwards and then the tyres can be replaced by moving backwards through a cylinder-led mobile clamp。Gear-retarding machineThe second is fixed to the bottom plate II, which provides power for the entire moving device. The coaxis are connected at one and both endsS scalding machineElectric one and silk bars for power transfer. The motor is fixed to the bottom and provides power for the whole of the device. This process is supported by some mechanical equipment, and there are differences between the equipment selected for different production requirements, with some details of the user ' s equipment being selected. Track 1 primarily provides guidance for the movement of workstations while providing some support. These are some details of the user's equipment. boserlS scalding machineIt is not easy to select a detailed model for matching use under the above conditions, so look at the configuration on the sample. The silk bars, in conjunction with the nut, transmit power to the workstation, which is firmly attached to the workstation. The models that can be matched at this time are s67, s77, s87, s97. Used tyres are a common environmental contaminant that, if not addressed, can pose significant environmental risks. Axis 2 and 3 are used to support the axis 1. The mobile clamps allow for back-to-back movement, allowing the entire cut-off to adjust to various types of tyres. when you cut a tyreS scalding machineElectric 2 is activated by rolling the active wheel through a joint axis 2 and a moving axis 1 and moving the movement through a moving belt to move the wheel from the moving wheel. The workstation is used for the filling of tyres. On the user's choice of the corresponding power for his equipment andS scalding machineIn the process, his request was to use 5900 wServo motor reducergroup as a driver for use. http://boserlgearreducer.com/product/list-sxiliejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: 5. 9kw/5900w power model size of s scalders