What's a speed-reducing machine with a big roller than a snail?

What's a big roller than a snail brake? Can a cut be tens of thousands? But this is just one of the requirements in the design of a scalder, accompanied by a twist and an output turn. Because for their equipment, individuallyGearbocIt is very slow to meet the requirements for use, so a combination of forms is required. So you can consult the technical staff of the b0serlreducing machine to analyse the model that you have chosen to determine whether the next model is consistent with the type you use. The other turbo-typereducing machine is larger, and theirreducing ratio can be nearly 300, which is the use of a singlereducing machine. The formula used to calculate thereducing ratio by thereducing machine shows that thereducing rate is smaller than the greater the output-reverse rate, and the twisting is larger. So what kind of brakes would be more appropriate on multiple parallels? Here's to see how we can choose a combination of the need for a turbinereducing machine. In some cases, the requirements of users are contradictory, and the deceleration ratio can be reached while it does not. In this contradiction, then, there is a compromise to choose a more appropriate way to use it on a mechanical basis. Since heavy or large equipment requires a larger output twister, it would be more appropriate at this point to select such a brake. what if this is what you needGear with motorYou can't be squared. What do you want to do? choose a similar deceleration ratio or look at the b0serl decelerator selection to see which of the closer deceleration ratios is more appropriate。

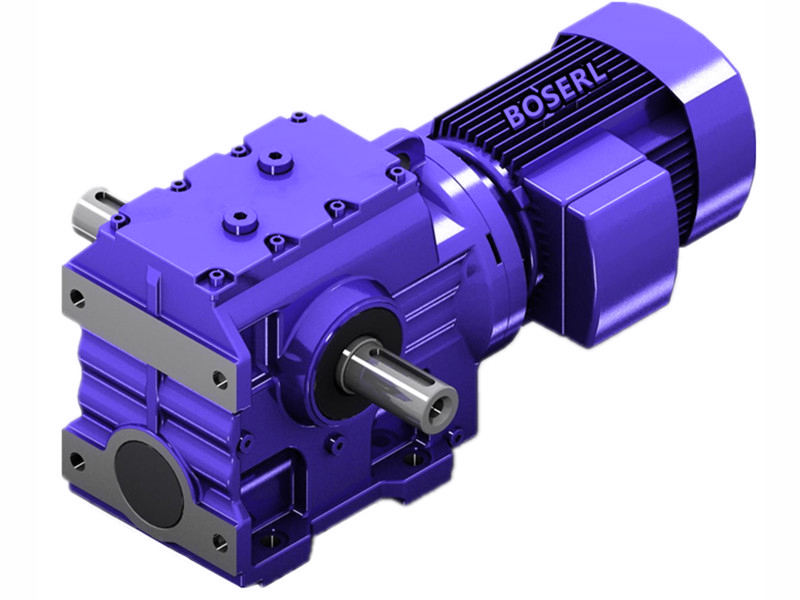

When equipment chooses to slow down, some of the equipment requirements are used for a variety of reasons, using a number of different sets of slow-down machines or a combination of electric machines. Some users are more commonSnail scalding, and for a turbine snail decelerator, the rate of a single decelerator is only 100, which means that other options would have to be considered if it had exceeded 100. When the ratio is high and there are twists and twists, we first need to know thecutting ratio. As in the case of the new combination, the deceleration ratio after the turbo reduction combination is the product of the previous two separate 075s. So how do you know how much of the combined turboreducing ratio is appropriate for your needs? It's up to you to ask for areducing machine, for example, if you need areducing ratio of 400, then you can combine two 20-to--reducing machines to meet thereducing requirements. However, there is often a need for some equipment forreducing machines that does not occur within these parameters, so what should be done with me? If the user's need is a snail brake machine, and the deceleration ratio is greater, there is one way in which we can satisfy his need for use, that is, to combine the brakes. A combination ofreducing machines has several characteristics, which are larger than, greater than, and lower than, output-reverse. It's simple to say if you want areducing machine to have as muchreducing ratio as possibleGeared motorthe gears have an impact, so the useful life is reduced. this combination is generally used on some of the larger equipment. so if your device is going to be such a gear-reducing machine, it could be in combination. http://boserlgearreducer.com/product/list-wolunwomenjiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: What's the big-wielder