How do you choose an acid-resistant alkali anti-corrosive stand-down?

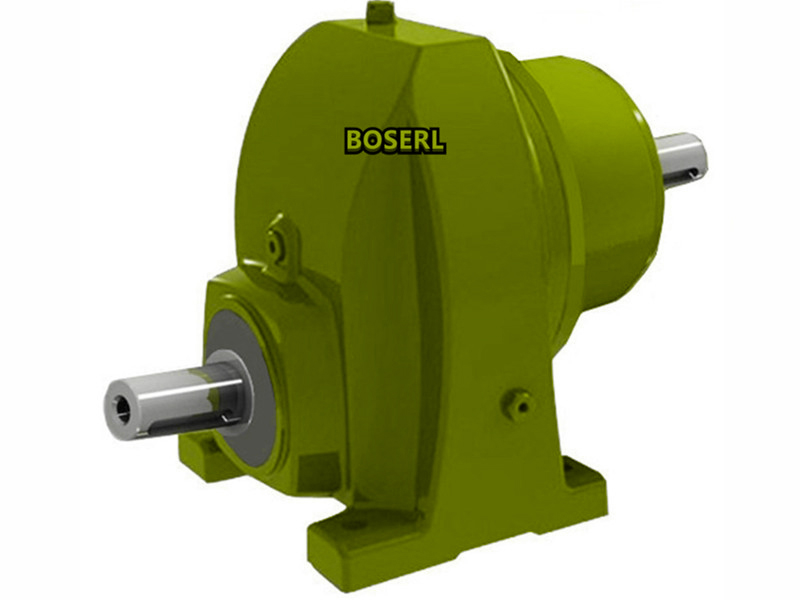

How do you choose an anti-acid alkali pre-corrosive flat-reducing device? How do you protect them from being a factor that enterprises need to take into account, for example, on a device? These are some of the more common cases of erosion, in which the surfaces of the mechanical equipment chosen and of thereducing machines need to be preservative and the prices of these specially treated devices are relatively high. Thus, in some exceptional cases, it is necessary to treat it in the light of the circumstances. Well, then, in these environments, it's a mechanical choiceStand-by gear brakesOr how do you choose the scalding machine? And what kind of protection level is needed to match the selection? See the details below. In some cases, they tend to be faced with a great deal of acidic chemicals, some alkaline chemicals, others with large amounts of salt fog. It can be used in such an environment after varnishing and treatment of thereducing machine ' s closedness. Let's take a look at the details. Further details will be provided on the environmental concentration topic. You can consult the b0serl expresser technologist or check the relevant information for details. In such cases, the choice is made in the light of the circumstances. Their environment may contain elements of erosion or, for example, exposure to directly eroded liquids. And the same is true of alkalinereducing machines. they're all embalmed in the form of varnishRight-angle shaft reducer motorIt's still a snail brake or an electric machine, and their materials are intolerant。

It is either cast iron or aluminium, and chemical reactions occur when it comes to acid or alkaline liquids, and oxygen in the air accelerates their response, and there may be erosion that leads to oil spills in thereducing cartons or to their collapse. Some are in a salty fog environment, where the requirements for verticalreducing machines are more stringent, and perhaps some environments need to be equipped not only for preservation, but also for blast protection. In the course of its use, it also requires an irregular inspection of whether the protective measures carried out were damaged. This is what we doGeared motorOr some of the topics often encountered by staff who provide the type ofcutting service. When a stand-byreducing machine requires acid resistance, his rationale is to perform corrosive treatment on the surface, at a time when a more terbby corrosive paint is needed to spray thereducing machine. Mechanical and mechanical devices are different from process decisions in different environments, in which case users need to know their own environment of use and use to match the corresponding machine. If it's acidic, then how do you choose the motor gears that are used on the equipment orServo motor reducerand? when you're in an acidic environment, you need acid-resistant brakes. in most of the above cases, there are industries in which chemicals are produced either in environmental or metallurgy. one common feature of these working environments is the easy erosion of machinery in such environments. http://boserlgearreducer.com/product/list-rfxilijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Anti-acid alkali pre-corrosion-resistant stand-downs