The f series speed-reducing machine with a 28300 w-responder mix is used on the particle dryer

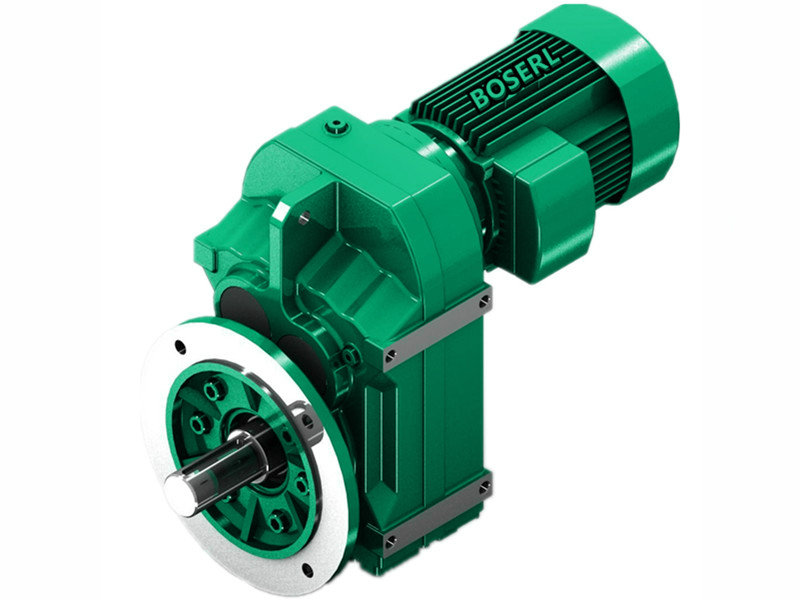

The f seriesreducing machine is used on the particle dryer with a combination of 28300 w. While the conveyor belt moves primarily by maintaining its position by a support pole, the vibrating electric power will drive the scrolling axis, which will then drive up and down the bottom of the conveyor belt using the driver ' s lifting point to drive up and down, so that the drug particles in the vehicle can be averaged by a gradual plough under the vibration, at which time the heating unit in the heating cavity will heat up the air in the heated cavity, with a sector of the air heating directly drying the drug particles from the wind to the upper part of the vehicle. when the carrierStand-by gear brakesWhen transported to the end of the conveyor belt, the drug particles will fall into the storage box with gravity, and the real drug particles at the entrance to the tank will be pushed to the deep of the tank using a pusher, which itself is a sealed c-shaped structure, so that the drug particles will not be stuck to the inside side of the pusher. The user's particle dryer consists of the shell, pump, dehumidifier, total wind pump, driver, heating device, feed mouth, heating cavity, delivery unit, installation frame, controller, storage tank, pusher pole, wheel, stationary frame, connector, winder, vibrating machine, conveyor belt, flat-flow winder, sub-hull, roller axle, material tank, vent, F series gear-reducing machine, etc. The device works by placing particles of the material in the substrates at the feed point, and then rotates with the driver-driven transmitter, when the material is delivered to the charger via the silo, and the motor-reducing wheel is synchronized with the gear movement during the rotation, thus enabling the vehicle and the conveyor to move in such a way that each trough can be positioned with an empty vehicle. Some of the materials need to be dryed and particulateized during the production of chemical or pharmaceutical products. As the user does not provide detailed parameter requirements, it is not easy to select a detailed model for use by the user, in which case you can download B0SERLGeared motorThe selection sample or the b0serlreducing machine technical staff provide you with a detailed design for thereducing machine。

An earlier user's request was to use a f-seriesreducing machine with a 28300 w to be used on the user's particle dryer, at a time when the equipment should use areducing machine and the corresponding matching machine to be able to satisfy the user's requirements. in the user's selection process, his request is to useInduction motorIt is not easy to select a suitable device for matching a user's particle dryer with a 28300 w machine, at a time when his dryer does not have other parameter requirements, and in such a case it is necessary to know some of the user's parameter requirements to match the suitable reduction machine for use. The other part was transported to the storage tank by areducing power-enabled winder to assist in drying, while the air located inside the shell was re-drinked from the pump and delivered to the dehumidifier for dehumidification, and the air subsequently treated in the dehumidifier was re-heated by a total wind pump back to the heating cavity, thus achieving a rapid rotation within the shell. The parameters that operate between different devices during the granular drying process are not uniform, so that in such a case a small device matching the actual circumstances is used. When the drying is complete, pulls out the storage box from the right side of the shell and pours out the already dry drug particles. The material can then be transported through the vent into the vehicle. the device is simple and efficient in achieving average stalls and rapid drying of drugs, and the drying process is not only possible by adjusting heating unitsDouble-hole output reductionthe of wind delivery of power and total wind-injecting pumps regulates dry strength, and can directly adjust the delivery of the drug, so that the material particles suitable for different grains can be quickly adapted to achieve good drying, and the flow of drugs in the discharge process can be controlled and can be effective in avoiding uneven distribution caused by the difficulty of controlling the flow of the drug particles' effluents, while the re-storage of the gear-reducing power machine can also be used by vibration gear-reducing machines, further progress is made in amortization average, effectively ensuring drying and high practical value. http://boserlgearreducer.com/product/list-fxiliijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Speed-reducing machines with a 28300 w-moder mix in the particle dryer