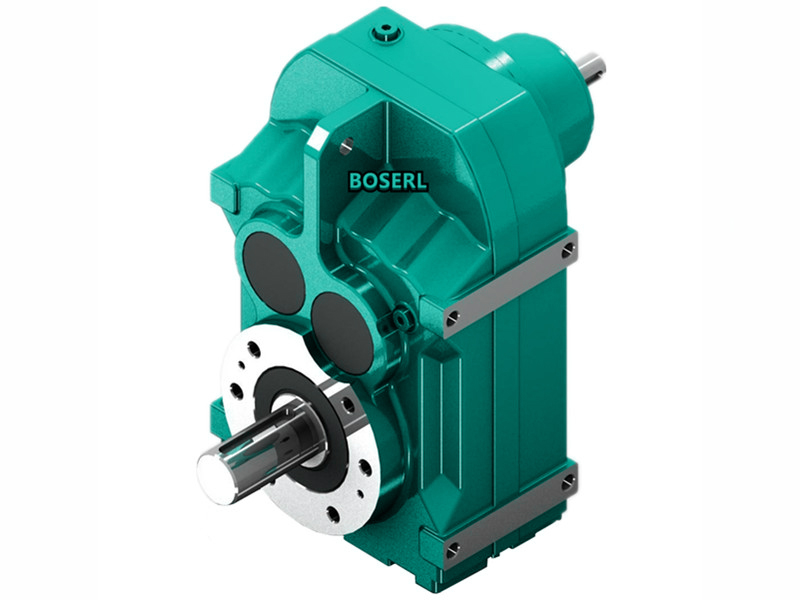

The dentures for the f series speed-reducing machines

Teeth for thereducing machine series f. The teeth are cleaned and ct-1 coated on four teeth. full cleaning of parallel axle gear gears, cleaning of teeth, ct-2 coating of four teeth, sealing of bearings, and protection against grindingMotor-gear reducerAxes. Checks the dentures of the gearing gears and requires compliance with the drawing requirements. At the end of the dents, the remaining cams of the gears, which are grinded at both ends along the long direction of the gears, are smoothed; parallel axle-reducing gears are cleaned clean, coloured, and the gestals of the gears are drawn with transparent tape; and thorough and careful cleaning is done to ensure cleaning. Cleaning fluids are optional for kerosene or for various types of washing agent. When the load and velocity are determined, the control time is a central indicator of the quality and efficiency of the rods, and when the teeth are taken, the grinding agent is painted on an average basis, and the contact with the grinding face of the run-off 5-10 shall be checked and the trends are captured, and then the re-advances are applied to thebox until the teeth qualify. gear loading: in f seriesGeared motorAn output axis with a fixed twister, the effects of which are in addition to ensuring that the rodents are in a state of continuous condensation and have a defined condensed pressure on their teeth, and that they are aware of the prerequisites for the development of the teeth。

When the rate of carving is low and the load is preponderant; when the gear is high and the load is small, the load must be undisturbed and cannot be changed at will. Examination of freckles in the gears of the f series for gear reduction machines, condensed to the drawings ' accuracy in the long direction of the teeth, in the centre of the teeth, in the high part of the exposure, around the round, and in case of contact with the teeth or the teeth, in the hard point of contact with the soft sands and the removal of the teeth or the roots, in principle only the large gears of the parallel axes are promised. it's by denturesInduction motorNoise, life expectancy indicators have improved significantly and client complaints have decreased significantly. the denture process: select the appropriate dentation method, first level up the test platform for the f seriesreducing machine and require a horizontal level

Pre-dental requirements: the rolling parts of the f series gear-reducing machines (including axle bearings or slide bearings, neck seals, etc. ), the main parts of the oil road, tube, hole, etc. , shall be closely and effectively sealed to avoid the entry of grinding agents in parallel axle-reducing machines. Checks for dentures, for looseness, to meet the operational requirements of dentures. In the manufacture of parallel axle-reducing machines, as a result of processing errors in the box, gear-processing errors, heat-processing deformations and assembly combination errors, in some cases, low dent exposure, reduced the useful life of the f-reducing machines and, in order to eliminate all types of error, progressive dent-exposures, improved corrosiveness of the dents, in addition to the measures taken in the process, could be studied in the assembly. gear load determined to beGearboc15-20% of the rated load. the wheeled high- axis should be flexible and free of anomalies, and can then begin to study the teeth, in a low-to-high- sequence, and the velocity and load of the teeth will follow the previous specifications. 0.05/10000 mm, then connected to loading equipment and found, requires a conoaxial degree of 0.01 mm, and then tightens the bolts of the convulsors and presses the whole device to the test platform. http://boserlgearreducer.com/product/list-fxiliijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: The dentures for the f series speed-reducing machines