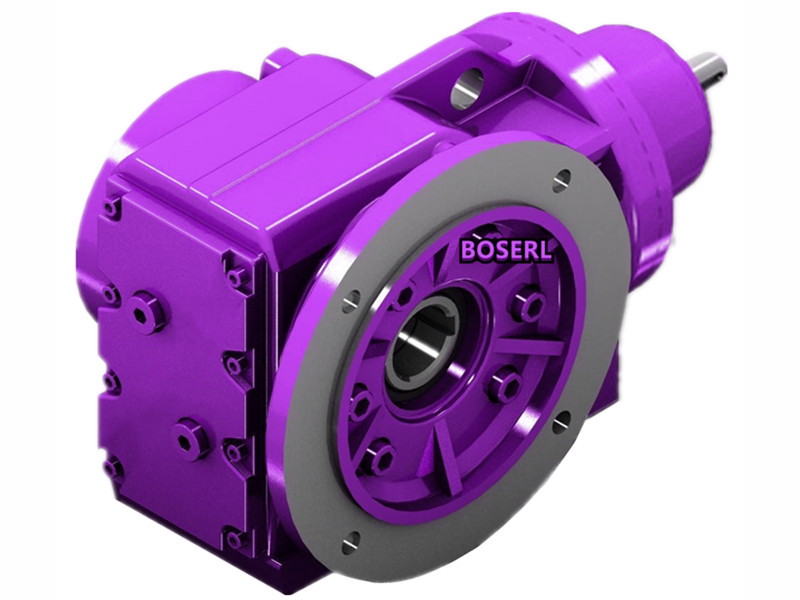

Points for periodic examination of the gears and bearings of the k-series slowing machines

Keys for periodic inspection of gears and bearings of the k-series slowing machines. Observe wear and tear of ball bearings, internal and external circles and shelf maintenance. In order to perform autonomous safety work, welding links are to be robust when welding is used, and all types of cylinders are to be used in accordance with welding and gas cutting safety protocols. The wrench must be tight when removing the bolt, with special care to slip the wrench, which cannot be removed and which can be welded off the nut. security requirement alert: all k seriesGeared motorThe examination staff must study the construction measures and work procedures in a genuine manner, all the examination staff must wear the proper work safety items, all those who operate the electrical welds must have an electrical welding certificate of qualification to be manipulated, strictly enforce the blackout system, perform power outages, check the electricity, signboards, and have exclusive supervision. The use of the welders must be done in accordance with the protocol, the reverse chain must be used in a prior manner to check the type of the chain, the chain is open and the chain must be operated in accordance with the relevant safety control protocol. Pre-testing of electricity to confirm that power has been out of service before registration; removal of high--end and low--end-end-to-wheel protection shelves from the k-series reduction machines. Each year, the gears and bearings of the cone gear reduction machines are subject to a scheduled security check, and the spare parts plan and the financing plan for repairs and repairs are based on the inspection. pull out the wheel and free the cone gearer at both ends; unload all the oil in the k-seriesreducing machine by defusing the oil, unconnect the upper and lower caps to the bolts and remove the upper caps through the back chain; move the gears to the wheel by intermittently moving the high- end to the wheel and observe the wear of the gears, while at the same time confirming the end of the gears by touching the tooth under static conditions; and move the axes with a small hammer to see the high- and low- end and shake handsRight-angle shaft reducer motorThe axes are used to observe the trajectories of the bearings, to observe the ball bearings and the wear of the bearings and the inner and inner circles of the bearings; and to clean the k series of brake bearings with diesel fuel to wash out all the oil muds in the bearings。

The point of the test is..Motor-gear reducerThe internal and external circle of the bearings, the rolls, the holding of the frame, the movement of the axis in the direction, etc. Are intact, while the axes are also washed. Inspection of the construction steps: fill out the inspection contact notification form and forward it to the dispatch room. Quality requirements and care: when replacing the k-seriesreducing gears and bearings, make sure that they are properly modeled and installed; the bearing bolts of the bearing bearings need to be tightened to prevent dust from contaminating the gear-reducing bearings of the cones, and the cushions and cushions cannot be missing when the bolts are attached, but they must be placed in order, while the nuts need to be robustly in place, evenly, but not too strong, but not too strong, and too strong for the connection rings. In the absence of a title, the gears and bearings will be installed sequentially and a new no. 90 gear oil will be injected, and in the event of an imminent replacement in case of a disagreement, in the event of a delay in the replacement of spare parts, a replacement of the back-up turbostat and maintenance of the replacement cone turbostat. in order to ensure the proper functioning of the k-series decelerators, extensionMotor gearedthe useful life. http://boserlgearreducer.com/product/list-kxiliejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Points for periodic inspection of the brake bearings