Emergency repair and maintenance methods for transformer frequency brakes to slow down electric generators

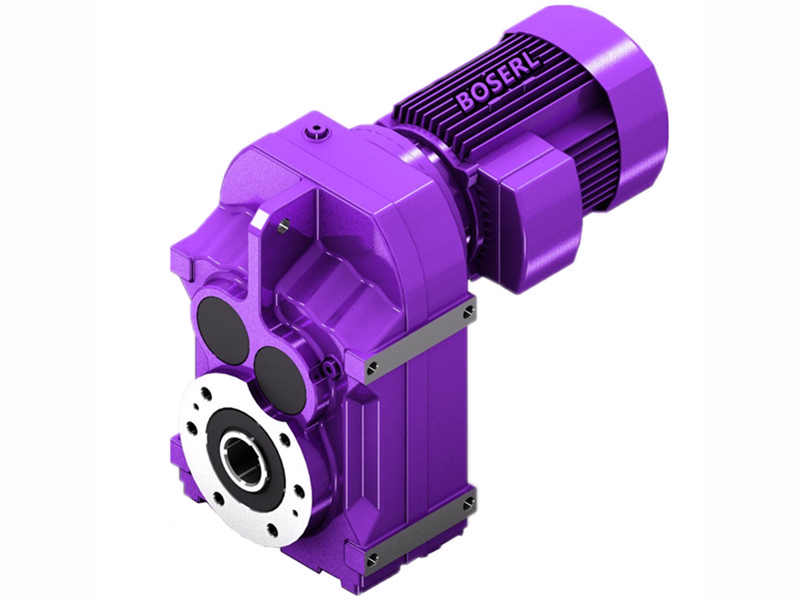

Emergency repair and maintenance methods for transformer brakes for reduction. If an empty cavity is applied in the slow, hardened, worn-out gear of a variable frequency brake, oil containing MoS2 is used. The temporary maintenance of the transformer brakes includes all fail-safe parts that are not guaranteed for normal use because of accidental break-ups or wear-out of components based on accurate protective measures. For the duration of the operationParallel axle reduction powerThe maintenance of the lubricant is well-functioning, and attention is paid to the following: The presence of metal particles from gears and the obscurity of oil in the taxis is recommended, a specialized laboratory is proposed to analyse the suitability of lubricant, the mixing of various types of lubricant is not permitted if the same type of oil has to be added to the tanks, time-tested instrument manipulation concentrations are checked, distance is determined, if the temperature of the transformer brakes exceeds 40° C in the environment, and the oil is checked every short period of time (the transformer brake motor lubricant, solvent and cleaning agent are toxic and harmful to humans: if exposure to the skin causes pain and sorrow, if inhalation causes severe poisoning, if ingestion causes death, the waste must be protected by a separate, suitable protection measure of the transformer brakes, and the waste must not be disposed of in the environment and assigned to toxic substances). Despite the adhesive decomposition, the addition of an attachment to lubricating oil as specified on the supply side and at the same time at the frequency brakeGeared motorInheritance to remain operational with reduced loads, and frequent checks are made on the efficiency of the motor lubricating system. For all applications requiring the limitation of the range of thereducing power plant, any two-rolling bearings with gaskets may be supplied, as required, and the thickness of the final pads may be determined on the basis of the actual axes of the bearings and the size of the frame。

The intent is to describe the manipulation of the removal and installation of units or components that require special procedures. Without taking into account the undamaged half-width and axle-direction compensation, in the latter caseDouble-hole output reductionThe change of axle bearing under constant control. A link that is more or less than the performance value will result in a different adjustment than anticipated. In order to avoid a reduction in the output of the transformer frequency brakes, emergency repair by the transformer brakes is often necessary for the duration of the emergency repairs. The following lists are some of the emergency repairs that were performed before the complete repair was undertaken: the re-engineering of axes that were different from those foreseen during the design period would result in a malfunction and damage to the machinery using this bearing. In the case of a broad starting point or crack on the gear edge of the transformer brakes, manual grinding, such as a wide-sector break, reduces the moving load. In the event of extensive damage to the side of the transformer brakes, such as severe point erosion and adhesion, symmetric gears (and fish skeletons) should be reversed, using the other side, without any need to reverse the point of the skeletal gear forward. These manipulations can be referred to as preventive and temporary maintenance. In selecting adjustments that would be more suitable for manipulating machines, the range of changes caused by the foreseeable axis link should be taken into account。Turn frequency brakes slowing downthe formula is valid only for the application of iron axes and racks. the following formula is used to calculate the terminal float system caused by interference. adjustments (sutures and preloads) are influenced by the number of bearings; adjustments for assembly bearings vary according to the connecting public difference, after re-engineered the internal parts of the transformer brakes. http://boserlgearreducer.com/product/list-faxiliejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Emergency repair and maintenance methods for slow-down generators