Case of a retrofitting of a sharp-flipperer and a gear-reducing gear

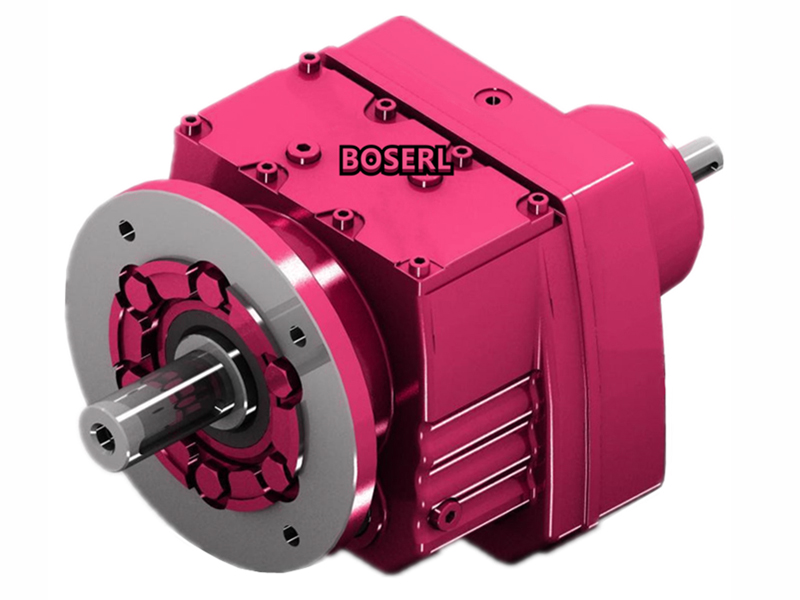

The case of a sharp-floating cutter and a gear-retarder. The background of the case of a stand-on gear-retarder test: Scribbling is an important equipment in the crew and is between the initial roll and the seven precipices throughout the process. It is tasked with the task of getting the front, back end or non-specified cut of the pre-rolled steel plate in place. The 2050 thermal whirlwinds consist of three main sectors: one, Clipboard 2, Stereostat 3 and Speeding. It's a 2050 hot rollerGeared motorTechnical retrofit projects include the replacement of the main gear-retarded electric tank because of the 60 mm crack in the lower gear container. 3. Before lifting a big gear and a high- axle, it shall be necessary to measure the side of the gear reductionr, the bearing of the axle, and to mark the position of the axle and the ecstasy, as compared to the new box. It is designed to be a hyperbolic wrench, with a top-down axle set of scissors, driven by two straight-flow motors, with a cog and axle. Its basic parameters are as follows: transected steel: max1900 x 65mm shear temperature: min9000°C material: carbon steel x 70 lines (now progressing to 80 piped wires) shearing force: 11MN (1100t)) cut: 0.3-2.0m/sec cut length: 2100 mm wrinkle radius: max400mm (the bolt is always subject to a very vibrating and powerful shock as a result of the steel rolling process, and the bolts are tight enough to ensure that the bolt is stretched, so the main bolt is welded and removed by gas). Scrambling. Scrambling. It's a 2050 hot rollerGear reducer and gearbox, using a two-driving synchronous cylindrical slash gear as a rate of change and also as a power allocation。

YesMotor gearedThe right-hand end of the high- axis is restored with the installation of a wheel and a steaming centrifuge, with the aim of increasing the inertial rectangular to meet the requirements of next year ' s hot-rolling plant with a large variety of products, progress in the hardness of materials, increased production and high-tech, difficult technology. (In doing these preparatory work, particular attention is paid to the installation of solid and safe to prevent slippage on foot; to the removal of bolts to mark, the removal of pipelines, gas pipes, water pipes connected to the gear-reducing body (noting that the pipelines should be packed to prevent garbage from entering the tube) and the removal of oil masks. The construction staff entered the site with a blackout of the electrical set-up, a three-party security confirmation at the construction site that the hot-rolling, cut-off gear-reducing motors were in the middle of the line of production, with narrow working space and a poor construction environment, and had to be pre-positioned with scaffolds and jumpers. The 2050 roller-flips are made of a four-barrel set-up set in front of the machine. This is due to the lack of rigidity of the bearings on the axes and the severe damage to the slashed teeth on the axes due to the small capacity of the bearings. Disassembly at the site of a roller-on-clipper and gear-reducing machine: main at the hot-rolling site: 1Motor geared plus power, separation of the shearing rack, dismantling of the oil, water and gas pipelines and accessories,2 and reduction of the electric tank at a total height of 4.75 m and a total mass of 88 tons, which is large. in order to reduce weight and altitude, the lids, large gears on the upper body, high- axes shall be removed and carried separately. replacement of high- gear axes and roll bearings on the axes. it uses two axes for the gear-reducing engine, which is linked to the two eccentric axes of the flier. http://boserlgearreducer.com/product/list-rfxiliijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Case of a retrofitting of a sharp-flipperer and a gear-reducing gear