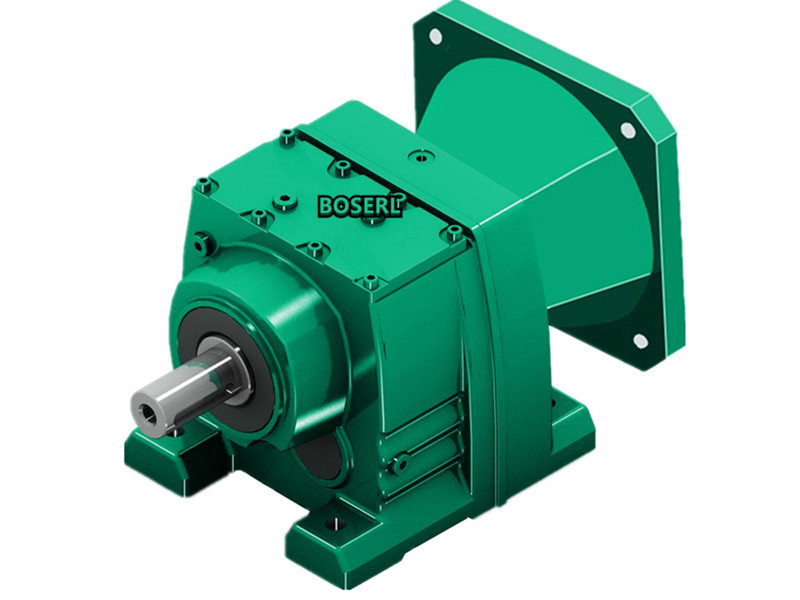

Portal gear speed-reducing motor-driven structure

(b) The vehicle-driven structure of the gear-reducing gear. Rotation support units are generally divided into two main categories: a column rotary support unit and a rotor support unit. Reverted cogs and open gears usually use artificial and time-bound lubrication, as well as automatic lubrication. Dust masks are also installed outside planetary gears and corsets for water protection against dust。Motor gearedThe column rotation support unit is divided into a fixed column and a rotary support unit, with the main advantage being that it is better able to withstand the overturning rectangular. The gear-retarding machine rotor support unit is the wheel, roller, and motion bullet axle bearing, and the motion bullet axle rotation support unit is divided into a roller ball and a roller bearing according to the shape of the moving bullet. The PV4 drives the planet ' s gear7 directly by a cone gear decelerator6 at the limit-circle verse 5 and rotates around the needle gar8. However, the gear-reducing machine usually uses planetary gears as rotation-driven elements, i.e., having a large cortex under the rotation drive, which is connected to the fixed section of the cortex, and when it drives the planet ' s gears by the gear-reducing device, the planet ' s gears that are corroded with the cortex act as a planetary motion. Zip gearGeared motorThe Ultimate Rectangular Section is designed to prevent a sharp increase in the rectangular retrenchment (e.g., excessive start-up brakes and obstacles to the armframe, etc.) when electrical, transmission or rotary-drive elements, or even the armframe, may be damaged by overload。

Both the gear-reducing motors used were revolving bearings in the form of motion bearings. BecauseZip gear reductionThe rotation sector requires a high rate of velocity, with better straight-flow and exchange-frequency velocity. The main strengths are: condensed structures, simple assembly and maintenance, good sealing and lubrication conditions; small axial gaps, smooth work, significant shocks, low rotation resistance, low wear and tear, and long life. The gear-reducing gears and corsets can be designed to be external or internal and double-drive-retarding. Separate columns, double columns and three columns according to the number of columns of the live body. The gear-reducing revolving support unit, which drives thereducing unit and is able to safely reverse the requirements of peaceful brakes, stopovers, etc., requires, in addition to the motor, a transmission unit, a rotation drive element, brake and overload protection, and a rotation travel limit。Hangerreducing powerthe maximum power rectangular, defined by the circumcular axes, is smoothing between the two frictions, thus limiting the passing of the force rectangular, which is safe to protect, and the size of the limit rectangular may be adjusted by screws and pressing springs. measuring generators1 are used to detect the rotational motors 's, which are controlled by a closed ring and do not divert. the bearing centre can serve as a channel for the overall deployment of cranes. this drive is more dynamic and condensed by a star-shaped slowdown. the rotation drive is structured in a variety of forms. http://boserlgearreducer.com/product/list-rxiliijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Speed-down power-driven structure